9

The tractor must be equipped with

working PTO shield. Never adjust or move the

driveline when connected to the tractor and the

tractor’s PTO drive is engaged to avoid serious

injury or death.

In some cases it will be necessary to shorten the PTO

driveline to match your specific tractor. Use the

following procedure to shorten the driveline.

1. Raise the 3-point hitch so the attachment gearbox

input shaft is in line with the tractor PTO shaft.

This position is produces the shortest distance

between the gearbox and tractor PTO shafts.

Shut down the tractor, leaving the attachment in

this position. Securely block the attachment in this

position.

2. Pull the driveline apart. Attach the outer (female)

section to the tractor PTO shaft. Make sure the

driveline is locked into place.

3. Hold the driveline sections parallel to each other

to determine if they are too long. Each section

should end approximately 3” short of the universal

joint shield on the opposite section. If the shaft is

too long, measure 3” back from the universal joint

and mark it on the opposite end. Do this to both

ends of the driveline.

IMPORTANT:

Do not cut the driveline until steps

4 and 5 have been completed.

4. Remove the blocks from under the attachment.

Raise and lower the attachment to determine the

position with the greatest distance between the

gearbox and tractor PTO shafts. Shut the tractor

off, leaving the attachment in this position.

Securely block the attachment in this position.

INSTRUCTIONS FOR SHORTENING THE DRIVELINE

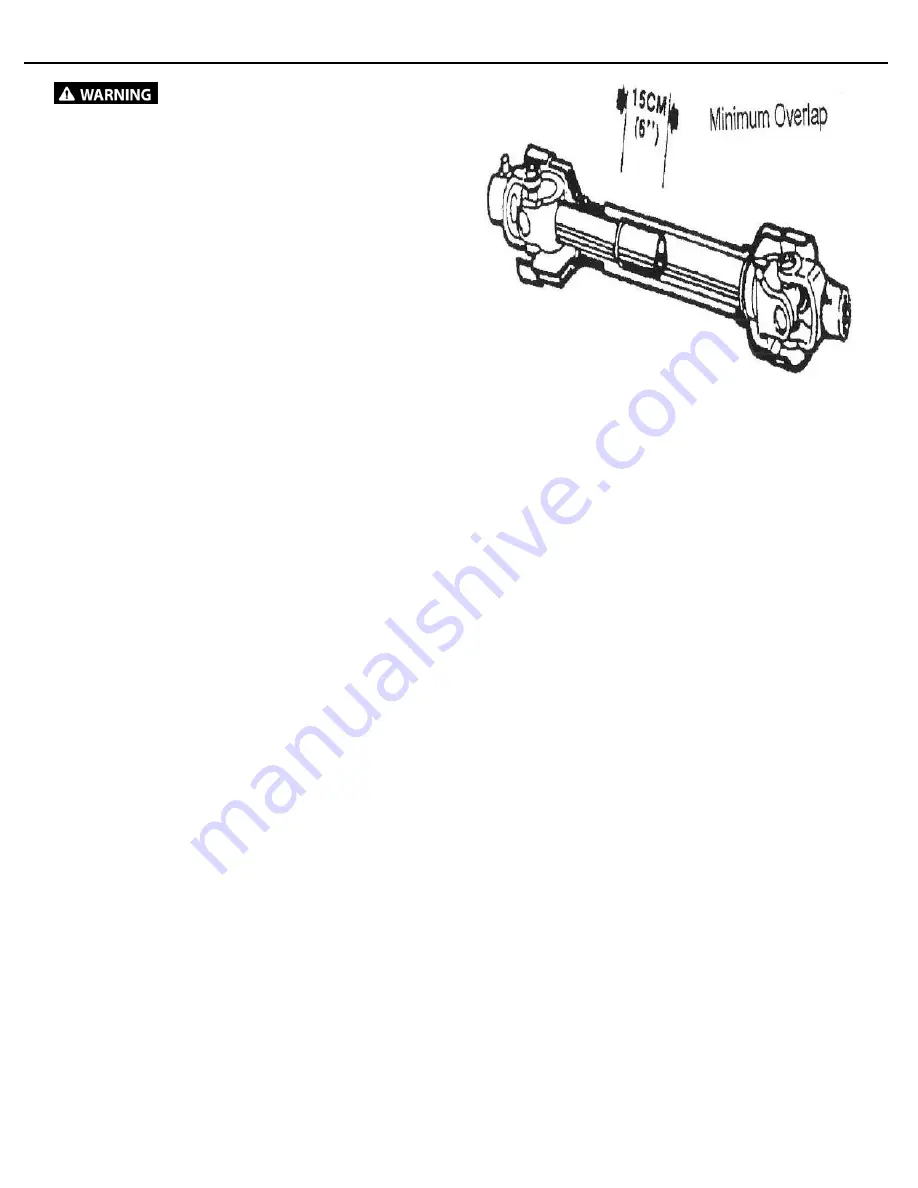

5. Hold the driveline sections parallel to each other

and check for a minimum 6” of overlap. Overlap

will be the distance between the marks made in

step 3.

6. If the driveline needs to be cut, remove the

marked section of the driveline and shield using a

hack saw.

7. Apply multi-purpose grease to the inside and

outside of both driveline ends and slide them

together.

8. Raise and lower the attachment to check that the

driveline assembly does not jam at any point. If it

does, cut equal amount off of each end, making

sure there is always at least 6” of overlap.

9. Check the full range of intended motion of the

attachment and make sure the swinging drawbar

on the tractor does not contact the driveline at any

point. If necessary, the drawbar can be moved

forward or removed on most tractors (refer to your

tractor’s operator’s manual).