Crack-Vac Model 100G Manual

Chapter 5 Operating Instructions

©2020 by Crafco, Inc. All Rights Reserved

Operating Instructions 5-1

5.0 Operating Instructions

Air quality, workers’ safety, and the safety of the motoring public are most important in today’s road

maintenance operations. The CRAFCO CRACK-VAC 100G was designed to thoroughly clean

pavement cracks while maintaining a dust free environment. With a HEPA filter system that

contains particulate matter down to .3 microns, The Crack-Vac 100G complies with the strict PM 2.5

air quality standards and OSHA standards for Respirable Crystalline Silica exposure in effect today.

This new concept in crack sealing preparation limits worker exposure to dust and improves visibility

problems that dust can cause for motoring traffic. The Crack-Vac is the future of crack cleaning

operations.

CRAFCO Inc. and its Distributors assume no liability for accident or injury incurred through

improper use of this machine.

DO NOT operate machine without reading operator’s manual and being thoroughly familiar with

controls.

Note:

DO NOT attempt to operate the machine without using these and all other instructions

.

5.1 Preparing the Machine for Start Up

Step

Action

1

All toggle switches and keys should be turned to the “OFF” position before doing

any work on the equipment. This will help prevent injuries.

2

Check engine crankcase oil. Add oil if low. Refer to Engine Operators Manual.

3

Fill engine gas tank with clean, fresh, unleaded gasoline. See “Fuel

Recommendations” in Engine Operators Manual.

4

Check engine cooling air intake and external surfaces of engine. Clean if dirty or

obstructed.

5

Check that the air cleaner components and all shrouds, equipment covers, and

guards are in place and securely fastened.

6

Check hydraulic fluid level in the hydraulic reservoir at 70°F. Use dexron III

transmission fluid. Add fluid as necessary. See

7

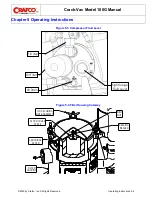

Check positive displacement rotary air blower fluid level. At ambient temperature

the oil should be at about the middle of the sight gauge. (Refer to the Blower

Manual). See

Figure 5-2 Rotary Blower Fluid Level

8

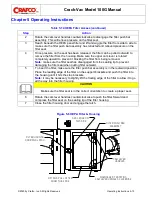

Check rotary screw compressor oil level. At ambient temperature the oil should be

between add and max arrows. (Compressor model only, use only VMAC

compressor oil). See

Figure 5-3 Compressor Fluid Level

9

Check to make sure that all the suction hoses are free from debris, kinks, or holes.

10

Check to make sure the pleat spun bond polyester cartridge filter is clean, in place,

and properly sealed. See

Figure 5-4 Filter Housing Cutaway

11

Check to make sure the filter housing is free of debris and clean. Make sure the

access lid is closed and properly secured. See

Figure 5-4 Filter Housing Cutaway

Table 5-1 Preparing the Machine for Start Up

Summary of Contents for 60800N

Page 1: ...CRACK VAC MODEL 100G Operator Parts Manual 26627N Revision O ...

Page 3: ...Crack Vac Model 100G Manual Revisions Revision Date ...

Page 4: ...CRACK VAC MODEL 100G with COMPRESSOR P N 60900N CRACK VAC MODEL 100G P N 60800N ...

Page 10: ......

Page 12: ......

Page 18: ......

Page 22: ......

Page 40: ......

Page 77: ......

Page 78: ... 2020 Crafco Inc ...