Crack-Vac Model 100G Manual

Chapter 6 Maintenance Instructions

©2020 by Crafco, Inc. All Rights Reserved

Maintenance Instructions 6-7

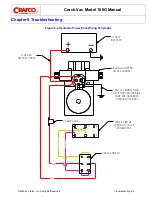

6.9 Rotary Air Blower

A good maintenance program will add years of service to your blower

Bearing Lubrication

Lubricate the drive end bearings every 40 hours of operation. Use NLGI #2 petroleum-based

grease with high temperature resistance and good mechanical stability. Use a pressure gun to force

new grease into each bearing until traces of clean grease come out of the relief fittings.

CAUTION

Do not inject grease too fast to avoid blowing out the drive shaft seal.

Oil service

Check and maintain oil level and add oil as necessary. Drain and refill oil after the first 100 hours of

operation and thereafter every 1000 hours, or more frequently depending on the type of oil and

operating temperature.

Oil capacity for the blower is 0.045 gallon (0.17 liters).

V-Belts

Re-tension belts after the first 8 hours of operation and check tension every 40 hours thereafter. To

check tension, place a straight edge across the belt span. Using a belt tension checker, push the

belt down midway between the pulleys and measure the deflection. Recommended deflection is ¼

inch with a 6lb force applied.

Inspect the belts regularly for signs of cracking or fraying. Replace the belts if they are showing

signs of wear. If one belt is showing signs of wear, replace all the belts together.

CAUTION

Over tightening the belts will cause shortened belt life and bearing failure of the blower and/or

engine. Do not use belt dressing on the V-belts. Keep sheaves and V-belts free of oil and grease.

Storing Procedures

If the machine is to remain inactive for extended periods of time, the unit should be stored in a dry

place. Protect the blower from corrosion; spray the interior of the blower (lobes, housing, and end

plates) with a rust preventative such as WD-40 to keep the blower from freezing up do to rust. If

possible, cap off the openings from air and moisture.

Remove tension from the drive belts.

When putting the machine back into service; spray the interior with penetrating oil and rotate the

drive shaft by hand to make sure the lobes will turn freely.

Re-tension the belts to the recommended tension. See section

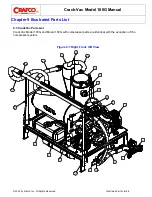

Summary of Contents for 60800N

Page 1: ...CRACK VAC MODEL 100G Operator Parts Manual 26627N Revision O ...

Page 3: ...Crack Vac Model 100G Manual Revisions Revision Date ...

Page 4: ...CRACK VAC MODEL 100G with COMPRESSOR P N 60900N CRACK VAC MODEL 100G P N 60800N ...

Page 10: ......

Page 12: ......

Page 18: ......

Page 22: ......

Page 40: ......

Page 77: ......

Page 78: ... 2020 Crafco Inc ...