�

�

�

��������������������

�

��

�

��

�

��

�

�

�

��������������������

�

��

�

��

�

��

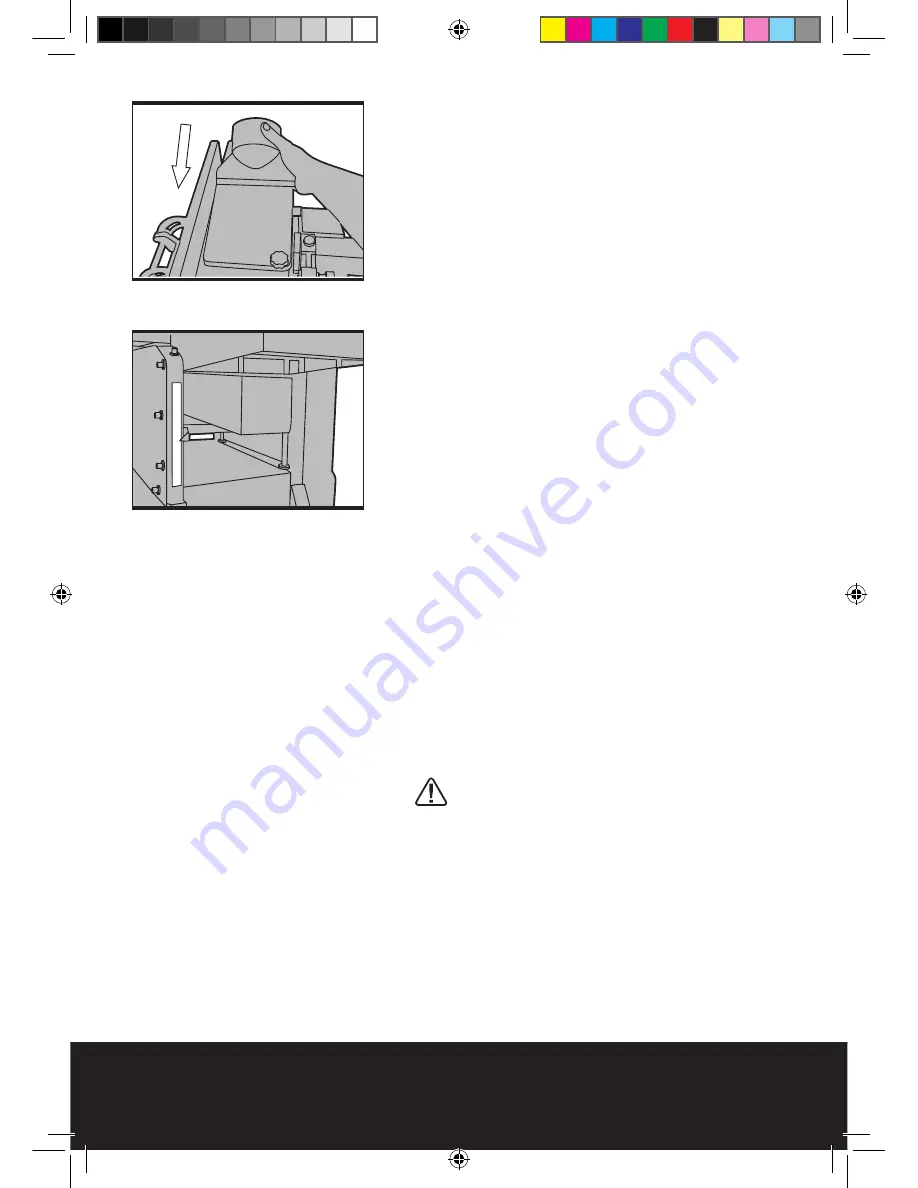

2.3 Thicknesser mode: Setting the depth of

cut. (See Fig 27)

The depth of cut is set by how high / low the

thicknessing bed is in relation to the cutter-block.

1) Measure the workpiece.

2) Set the bed to just over this measurement,

using the scale to the left of the in-feed table.

3) Turn the height adjusting handle (11) anti-

clockwise to lower the thicknessing bed, clockwise

to raise it.

4) Ensure that the cutter block is free from

foreign objects (including the workpiece to be

thickened).

5) Connect the planer thicknesser to the mains

supply.

6) Turn the thicknesser on with the green “1”

button (1).

7) Allow the planer to reach its maximum speed.

8) Place the workpiece onto the in-feed table.

9) Turn the height adjustment handle (11) half a

turn clockwise to raise the bed.

10) Continue this process until the workpiece

comes into contact with the thicknesser drive

rollers.

11) Once the workpiece comes into contact with

the rollers they will automatically “pull” it through

the machine and over the cutterblock.

12) Continue this process until the workpiece is at

the desired thickness.

Note:

A longer workpiece should be supported

after it leaves the machine to ensure a good even

finish.

MAINTENANCE

Caution:

Always ensure that the machine

is turned off and that the plug is removed

from the mains supply before carrying out any

repairs or maintenance.

1. Before each use.

• Check for damaged parts and repair or replace

them as necessary.

• Ensure all nuts and bolts etc are secure.

• Ensure that all moving parts move freely and are

not binding prior to starting the machine.

• Remove adjusting keys and wrenches and check

to see that keys and adjusting wrenches are

Fig 27

Fig 26

BTP210F-M-070928.indd 18

2007-9-28 13:35:59