selected, all parameters will be set to zero, and will need to

be entered manually. Parameters entered while using batch

0 are never stored (i.e. the “0” batch is a scratch memory

location). Parameters for all other batches are stored, so the

next time that particular batch is called, those parameters will

be presented as defaults. If any parameters are edited, the

new values will be stored for the next time that batch is

entered. All batches that have parameters stored can be

edited by entering the desired batch number.

CREATING A NEW BATCH:

Enter the number on the last line of the batch prompt screen,

in this case 1. The first edit screen will appear:

Length units IN #1 (Use + or - key to change to mm)

Length 0.00

Length compensation 0

Quantity 0

The current batch number is shown beside the # at the top

right. The cursor will be flashing just before the in (inch),

indicating that the field is currently editable. In general, the

line being edited will display a blinking cursor. Press ENTER

to accept the default of inches, or press the “+” or “-“ key to

toggle to mm, for millimeters, then press ENTER to store

mm. Each time ENTER is pressed, the cursor advances to

the next parameter.

Enter a value for the length parameter. If ENTER is pressed

accidentally before a value is entered, a long error beep will

sound, otherwise the entered value will be stored. If a mistake

is made, press the BS key to back space over the entry. If the

enter key has been pressed, press the ESC key and start

over. All values entered so far will have been stored, so you

would only have to press ENTER until you returned to the

place where you wanted to make a change-the values would

not have to be entered again. Any value between .01 and

23,300 may be entered. This allows for 5 digits before the

decimal place and 2 digits after. In mm mode, only 1 decimal

place is allowed after the decimal point and 6 digits in front of

the decimal.

Due to variations in materials, pre-feed systems and belt

tension, actual cut length may vary from the inputted length

by a proportional amount. The WC601B incorporates a length

compensation feature to provide an easy adjustment in these

cases. The length can be compe/-1% to +/- 99% of

the inputted length. The length compensation display will

show (-) for a negative value. Example: If 10" (254mm) is

entered as the desired length, but the actual cut pieces

measure 9.8" (249mm), a length compensation of +2% will

increase the cut length by .200 (5mm) to the desired 10"

(254). The default is 0, or the “+” or “-” keys may be used to

add or decrease length compensation of plus or minus 1 -

99% of the inputted length. NOTE: Often it will not be known

if length compensation is needed until after a trial run is

completed. When programming a batch, leave the field at 0

and edit the batch later if necessary to add length compen-

sation. Once a value has been entered, or if the default of 0

is to be used, press ENTER. The length compensation will

remain with the batch program. An alternate, more accurate,

method would be simply to enter the desired cut length,

measure the error and add/subtract the error to/from the

targeted length (e.g. a desired 10.00” is entered into the

length parameter; a measured 9.82” is cut. The operator

compensates for this by adding 0.18” to the targeted cut

length value. The new cut length value becomes 10.18”).

ENTER THE QUANTITY OF CUT DESIRED - UP TO 999,999.

Rate Screen:

Feed Rate 3

#x

(Enter 1 thru 9, rate #3 is default.

x=current batch number)

Initial Rate 1500

Final Rate 8600

Acceleration 18

After the quantity is entered, the rate edit screen appears.

Press “+” or “-” to increment or decrement the feed rate value.

Alternately, the desired feed rate may be entered manually

(any number between 1 and 9). As the value is changed, the

rate values are updated to show what values are active for that

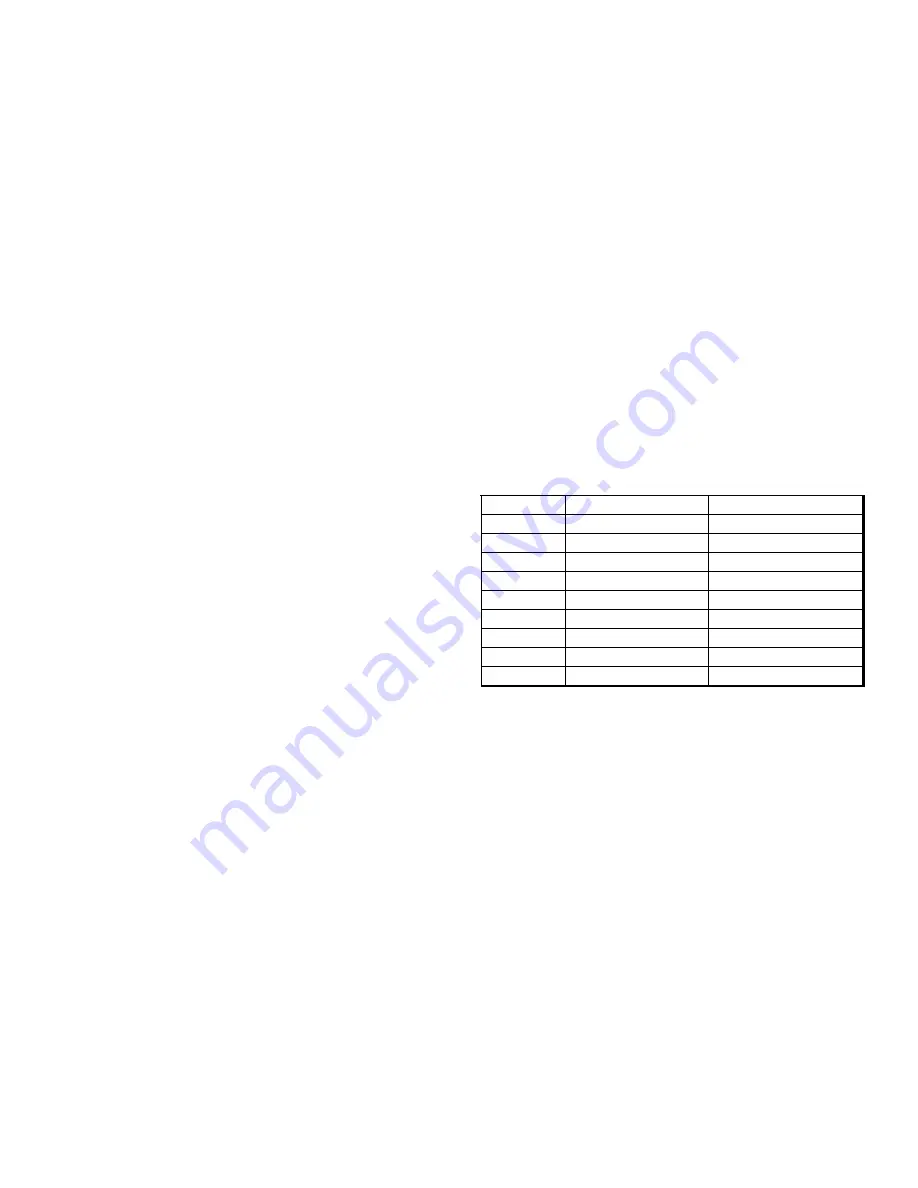

feed rate. The following table represents the maximum speed

at any feed rate of the feed belts:

NOTE: The slower the feed rate, the more accurate in length

the cut pieces will be. It is advised to start with the lowest feed

rate and check results, then adjust the feed rate if desired.

Cutter Screen:

Cutter Parameters

Cut Speed 6

(Enter 1 thru 9, 6 is default)

Cut Time 1.000 (Enter 0.1 to any number of seconds, 1 is default)

The cut speed controls the speed and pressure at which the

rotary blade cuts through the material. If material does not cut

completely through, increase the speed control. If cut is not

clean enough, decrease the speed control. The cut time can

be changed for materials of different hardness. Average cut on

times are from 0.5 second to 2 seconds. The blade speed and

cut time should be set as low as possible to give the best

possible cut. There are 9 cut speeds that allow incremental

adjustment of the rotary speed of the cut head (typically 750

RPM to 1900RPM).

After the Cut Time is entered, the display under “Cut Time

x.xxx” will show: “Press Run to Start”. Press RUN or ENTER

to begin the cutting cycle of the tubing cutter.

Run Screen:

Feed Rate # Linear Speed (in/sec) Linear Speed (mm/sec)

1

5.7

144

2

8

203

3

12.2

309

4

16.6

421

5

20.8

528

6

25.1

637

7

29.3

744

8

33.4

848

9

39.8

1011