5

NOTE: Never work under the raised dump

box without using the safety arm to prevent

the box from falling down.

All four stabilizers and rollback must be

fully extended when greasing fittings on the

RB4000.

Greasing guidelines vary slightly on pre-

2014 RB4000 units. For older units, contact

the manufacturer’s recommended service

provider (Index A) for guidance on grease

locations.

Use provided grease tube to apply lubricant

to the following areas on all units:

L U B R I C A T E F I T T I N G S

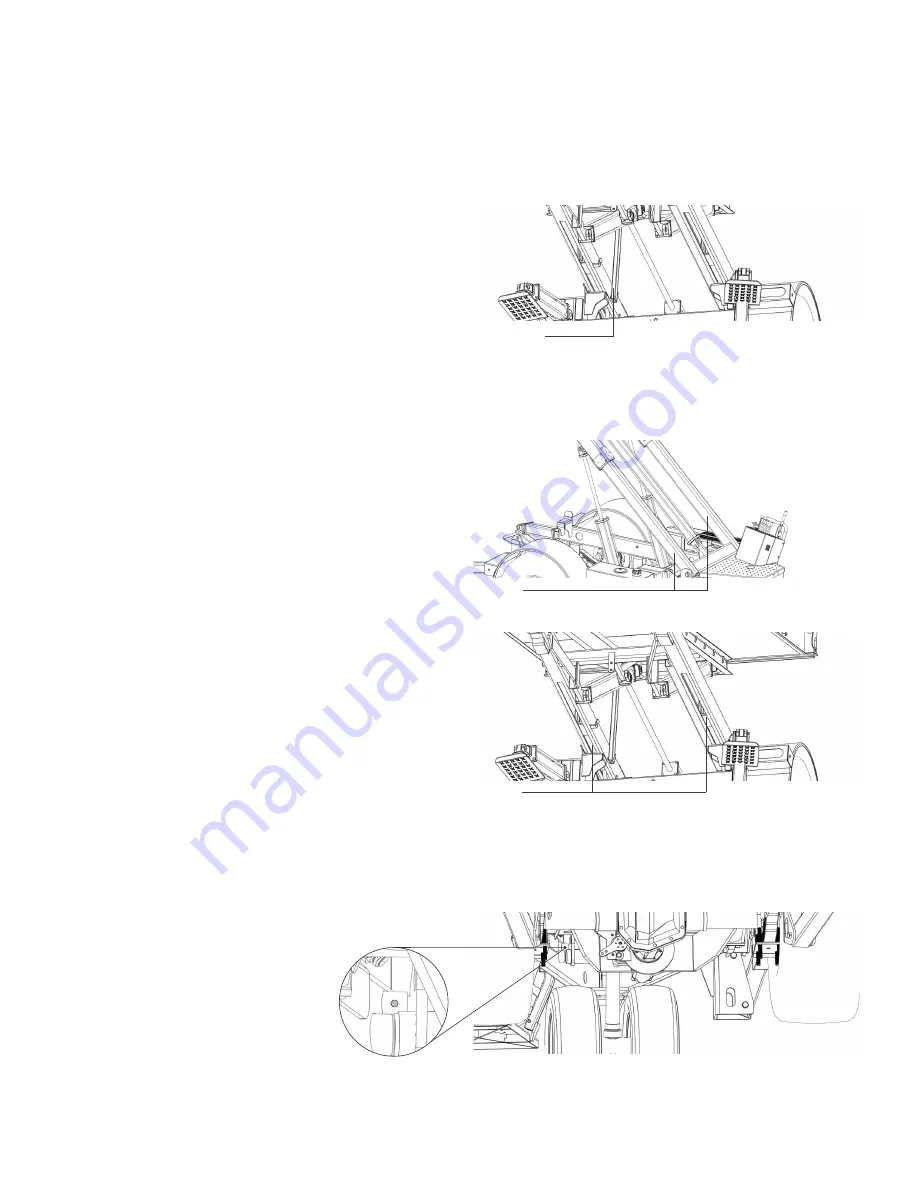

Slide Rails

NOTE: Use provided gloves to apply the

grease to slide rails directly.

1. With the rollback fully extended, grease

the 3” x 5” tubes.

2. Grease the inside of the 4” x 6” tubes.

Wheel Lock Pin

NOTE: This step is applicable

for units manufactured on or

before October 2019. Units after

October 2019 are equipped with a

greaseless bushing.

1. Reach under the wheel lock

guard.

2. Insert grease into the zerk.

3. Pull the wheel lock handle and

grease the pin.

Step 1

Step 2

Safety Arm

Summary of Contents for RB4000

Page 1: ...R B 4 0 0 0 S E R V I C E M A N U A L ...

Page 2: ......

Page 12: ...8 ...

Page 15: ......