LIMITED WARRANTY

Your new

EQUIPEX

product is warranted to the original purchaser for a period of one year from the date of purchase.

This limited warranty is against defects from original factory imperfections in material and/or workmanship

and includes labor for replacement of defective parts, provided repairs are performed by an authorized service

agency. Our obligation under this warranty is limited to repairing or replacing any part or parts thereof. The

CUSTOMER must inform the Service Agency of warranty coverage and provide a copy of the dated sales or

delivery receipt BEFORE WARRANTY REPAIRS BEGIN. Replacement parts and accessories are warranted for

ninety (90) days from the date of purchase when purchased separately and will be verified by dated sales receipt or

packing slip for that item. All parts or accessories replaced under warranty must be returned to the Service Agency.

This warranty applies only to equipment under normal use and service in the U.S.A. and Canada. It does not

apply to any item which has been repaired or altered in any way so as, in the judgment of EQUIPEX, to affect its

reliability.

THE FOLLOWING ARE NOT COVERED UNDER WARRANTY:

1. Damage caused by abuse, misuse or dropping or other similar incidental damage caused by, or as a

result of, customer failure to follow assembly, operation, cleaning, user maintenance or storage

instructions.

2. Labor to replace inoperative parts such as bulbs, plugs or racks due to normal wear and tear or abuse.

3. Materials or labor to repair scratched, stained, chipped, pitted, dented or discolored surfaces, attachments or

accessories.

4. Transportation charges to or from a service agency for repair of your machine. If you should have

questions relating to this issue, please call

Equipex

at 1-800-649-7885.

5. Labor charges to install or

test attachments or accessories, which are replaced for any reason.

6. SHIPPING DAMAGES. Visible and hidden damages are the responsibility of the freight carrier.

The consignee must file the claim promptly against the carrier. KEEP ALL ORIGINAL

CONTAINERS AND PACKAGING MATERIAL FOR CARRIER INSPECTION.

7. Products placed or stored in the equipment are not subject to this warranty and no responsibility is

assumed thereof.

THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A PARTICULAR PURPOSE AND

CONSTITUTES THE ONLY WARRANTY MADE BY EQUIPEX, LLC. IT NEITHER ASSUMES, NOR AUTHORIZES

ANY PERSON TO ASSUME FOR US, ANY OTHER LIABILI TY IN CONNECTION WITH THE SALE OF THE

SUBJECT EQUIPMENT.

For service, please call

EQUIPEX

at 1-800-649-7885, menu option # 3

765 Westminster Street

Providence, Rhode Island 02903

U.S.A.

Tel: (401) 273-3300 Fax: (401) 273-3328

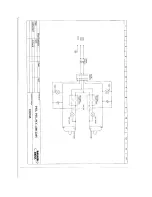

Summary of Contents for SODIR PCC-400

Page 6: ...Spare Parts PSE 400 ...

Page 8: ...PSE 600 ...

Page 10: ...PSS 400 ...

Page 12: ...PSS 600 ...

Page 14: ...PSS 900 ...

Page 16: ...PCC 400 ...

Page 18: ...PCC 600 ...

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......