Chapter 2 Setup

59

2

Setting the Memory Switches and R/E

W

it

h

t

he memory sw

it

ches a

n

d R/E (rece

i

p

t

e

n

ha

n

ceme

nt

) f

un

c

ti

o

n

, wh

i

ch are sof

t

ware se

tting

s

for

t

he pr

int

er, yo

u

ca

n

se

t

t

he var

i

o

u

s f

un

c

ti

o

n

s.

For a

n

o

ut

l

in

e of

t

he f

un

c

ti

o

n

s, see

t

he follow

ing

sec

ti

o

n

. Use

t

he me

t

hods show

n

in

t

he

t

able

below; TM-S9000 U

ti

l

it

y or Memory Sw

it

ch Se

tting

Mode

t

o se

t

t

he memory sw

it

ches a

n

d R/E

f

un

c

ti

o

n

s.

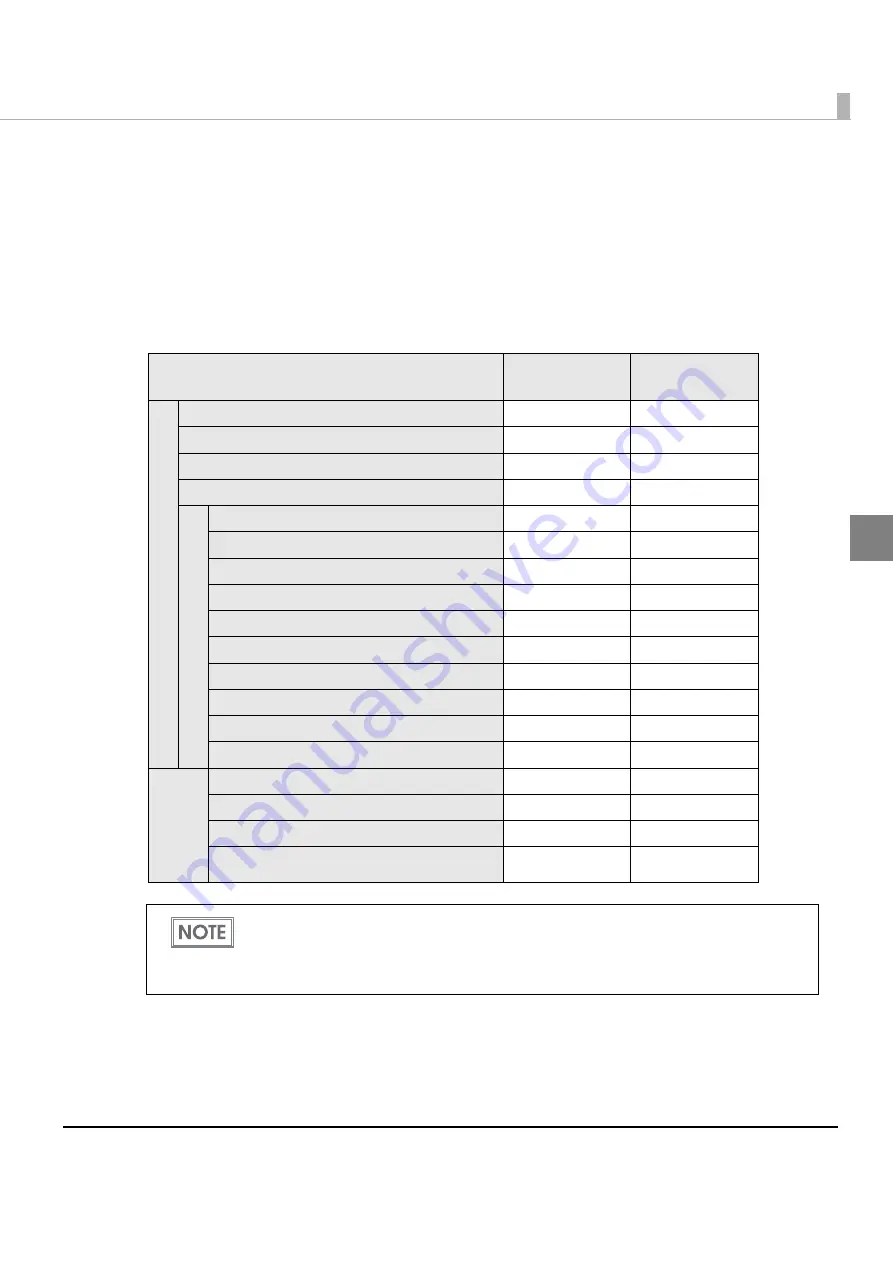

Settings/Setttings Methods

TM-S9000

Utility

Memory Switch

Setting Mode

Memor

y

S

w

itches

Power ON information

✓

✓

Auto line feed

✓

✓

Remote wake-up

✓

✓

Roll paper cover open during printing

✓

✓

Customized

Value

s

Print density (roll paper)

✓

✓

Cut paper when the cover is closed

✓

✓

Roll Paper Reduction Settings

✓

✓

Multi-tone print density

✓

✓

Time to check ink head cleaning

✓

Top margin for validation

✓

Left margin for validation

✓

Top margin for cut sheet paper

✓

Left margin for cut sheet paper

✓

Time to enter power saving mode

✓

Rec

e

ipt

Enhancement

Top/Bottom logo print setting

✓

Print top logo when paper is cut

✓

Print top logo when device is powered on

✓

Print top logo when cover is closed

✓

For detailed information about the TM-S9000 Utility, see the

TM-S9000 Utility User’s

Manual

.

For information about how to use the memory switch setting mode, see