Installing the Touch Unit

96

b

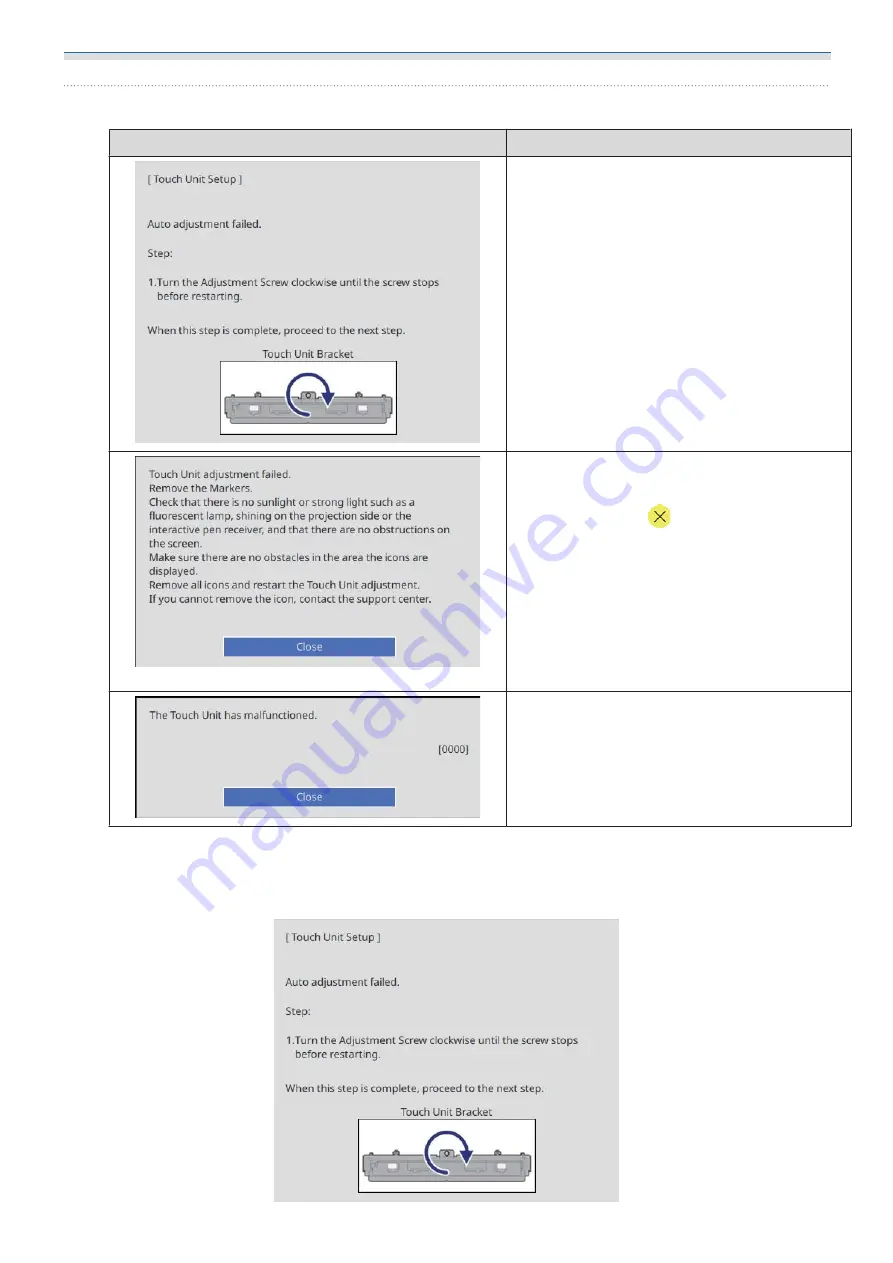

Check the message displayed and take the necessary action

Screen

Solution

Follow the on-screen instructions to adjust the

angle of the laser, and then perform auto adjust‐

ment again. For details, see "Adjusting the angle

of the laser"

.

Check the following after removing the markers

from the projection surface.

If you see an icon (

) on the projection surface,

check if there are any obstacles at the position of

the icon.

Check if the strong light such as sunlight or fluo‐

rescent light is shining onto the projection sur‐

face or the interactive light receiver.

When you have checked everything, perform

Touch Unit Setup

from the

Installation

menu.

The Touch Unit may be malfunctioning. Contact

your dealer.

Adjusting the angle of the laser

This section explains how to re-adjust the laser when you see the following screen.