13

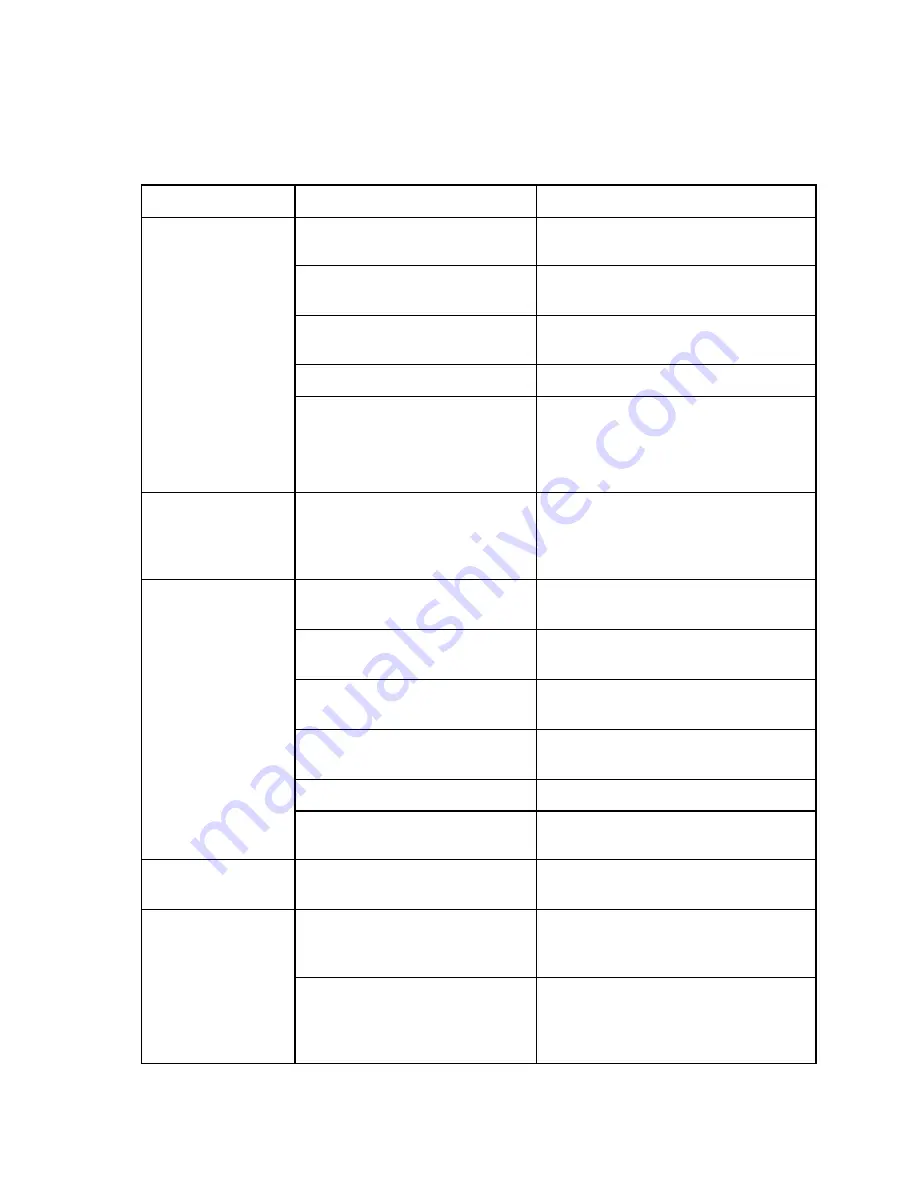

4 Trouble Shooting

Trouble

Possible Cause

Measures

Paper stuck just after it is printed

Loosen the paper sufficiently or feed the

paper after it is dry.

Stains on the paper separator

Clean the paper feed separator using the

unit cleaner.

The paper is not fed

Stains on the paper feed rubber roller.

Clean the paper chips or ink on the paper

feed roller with the unit cleaner.

(slipped)

The paper separator is worn out.

Replace the paper separator with a new one.

The volume of the paper loaded on

the paper feed table is not enough.

If the volume on the paper feed table is not

enough, it does not feed since the paper

detection lever is installed. Load 20 sheets

or more.

The machine does not

operate even after the

Start/Stop key is

pressed.

Paper jam inside the unit.

Detach Table 1 and 2 and remove the paper

in the unit.

Paper stuck just after it is printed

Loosen the paper sufficiently or feed the

paper after it is dry.

Stains on the paper separator

Clean the paper separator using the unit

cleaner.

Stains on the paper feed roller

Clean the paper chips or ink on the paper

feed roller with the unit cleaner.

Wrinkles appear on the

paper.

Stains on four paper fold rollers

Clean the stain on four fold rollers using the

unit cleaner.

Table 1 and 2 are not properly set.

Reset properly.

Paper jam in Table 1 and 2

Detach Table 1 and 2 and remove the

jammed paper out.

Improper fold position

The total length of the paper is not

standard size.

Measure the total length of the paper and

adjust using the fine adjustment knob

The surface of four fold rollers are

stains with paper chips or ink (slippery

situation)

Clean away the stain on four fold rollers

using the unit cleaner.

Drawing paper (125kg

or lighter) cannot be

folded.

Low room temperature

The paper gets stiff and hard to fold at the

low room temperature in winter. Perform

folding after leaving the paper as it is for 3 to

4 hours at the temperature of 20 to 25 C.