Fuel Conversion

14

Figure 12: Removing valve

screw.

Figure 13: Flip valve

screw.

Figure 14: O-ring on valve screw.

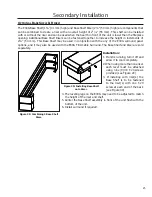

Figure 15. Ignitor assembly

beside the burner.

d) Insert a

5

/

32

” or 4 mm Allen wrench into the hexagonal key-way of the screw (see Figure

12), rotate it counter-clockwise until it is free and extract it.

e) Flip the screw (refer to Figure 13).

f) Using the Allen wrench as shown in Figure 12, rotate the screw clockwise.

WARNING!

Do not

over tighten the screw.

g) Verify that if the conversion is from NG to LPG, the screw must be re-assembled with the red

o-ring visible (refer to Figure 14). If the conversion is from LPG to NG, the red o-ring of the

screw must not be visible.

h) Re-attach the black protection cap that was removed in step “c)”. Refer to Figure 11.

i) Reinstall the knob extensions. They are keyed into the notch on the knob.

j) Reinstall the Valve Cover plate.

8. Reinstall the burner, porcelain panels, glass beads,

and glass door. Also refer to

s

econDary

I

nstallatIon

- F

Irebox

l

Iner

anD

b

urner

t

ray

r

emoVal

in your

Owner’s Manual. When re-installing the burner,

ensure that the burner to pilot hood relationship

is similar to what is shown in Figure 15. On some

units you will need to pay special attention when

installing the burner that the venturi adjustment

rod is properly installed into the venturi adjustment

piece welded to the burner venturi tube

9. Reconnect the main gas line if it was disconnected

and open the shut-off valve at the gas line to the

unit.

10. Use a small brush to apply a warm soapy water

solution to all gas connections (use half dish soap

and half warm water). If a gas leak is present,

bubbling will occur. Gas leaks can be repaired by using an approved pipe thread sealant or

approved Teflon tape. NEVER USE AN OPEN FLAME WHEN TESTING FOR LEAKS.

11. Reconnect the electrical power to the unit.

12. Relight the main burner in both the “HI” and “LO” positions to verify proper burner ignition and

operation and proper flame appearance.

13. MAKE SURE that the conversion label is installed on or close to the rating label to signify that the

unit has been converted to a different fuel type.