WARNING:

After lifting is completed, always support

the load using the proper Enerpac U-Rings or

appropriately rated load supports. Never rely on the

cylinder's hydraulic pressure to support the lifted load.

WARNING:

Wait an appropriate amount of time before

working under the load after it is supported by U-Rings

or load supports. Any settling of jack base or load

supports into the ground below must not exceed 1/4 inch [6.4

mm]. If additional settling occurs, reposition jack or load supports

on solid ground.

IMPORTANT:

if there is to be no cylinder movement for more

than one minute, it is recommended that the motor be turned

off to prevent overheating of pump and air motor (models with

manual control valve only).

TO LOWER THE LOAD:

1. Be sure the control valve lever is in the center (neutral/hold)

position. If jack is equipped with pendant, be sure that both

buttons are released (not pressed) so that valve returns back

to the center position.

2. Open the air supply valve. On models equipped with a

manual control valve, the motor will start.

3.

Move the control valve lever to the extend position or depress

the pendant up-arrow button. Allow cylinder to advance a

small amount, so that load is lifted off of U-Rings or clears

the load supports. Then place the control valve lever in the

center (neutral/hold) position or release the up-arrow button.

4. After the U-Rings or load supports are removed, move the

control valve lever to the retract position or depress the

pendant down-arrow button to retract the cylinder.

CAUTION:

Be careful while lowering to ensure that the

load is lowered evenly, so that load shifting does not

occur.

5. When load has been fully lowered, place the control valve

lever in the center (neutral/hold) position or release the

pendant down-arrow button. On models with manual control

valve, close the air supply valve to stop the motor.

AFTER COMPLETING THE JOB:

Fully retract the cylinder and close the air supply valve. With the

motor off , shift the control valve several times between the extend

and retract positions to relieve system pressure.

Disconnect the air supply hose and remove any extensions or

spacers from the cylinder. Place U-Rings (if used) on the storage

rack provided on the jack.

Always store the jack and its accessories in a clean and dry area,

free of moisture and direct sunlight.

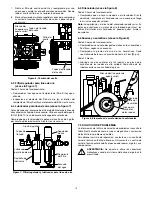

5.4 Stacking Instructions - Extensions and Spacers

(See Figure 4)

Extensions and spacers are available as optional accessories

from your Enerpac authorized distributor. They may be ordered

individually or in sets. Refer to tables 3 and 4 for additional

information.

PRE Series extensions allow the jack's useful lifting height to

be increased in increments of 5, 7, 9 or 11 inches [127, 178,

229 or 279 mm]. On short stroke Pow'r-Riser models only, larger

extensions can also be used, allowing the useful lifting height to

be increased in increments of 14 or 18 inches [356 or 457 mm].

PRS Series spacers

allow additional fi ne adjustment of the

extension stack height. They may be used alone or in conjunction

with PRE Series extensions.

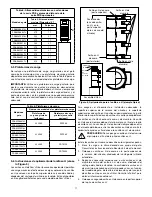

Table 3 - PRE Series Extensions (optional accessories)

Extension

Model

Thickness (each)

inches

mm

PRE5

5

127

PRE7

7

178

PRE9

9

229

PRE11

11

279

PRE14

*

14

356

PRE18

*

18

457

PRES6024

Extension Set

Includes PRE5, PRE7, PRE11 and PRE18 (1 each).

*

For use on short stroke jacks only (models ending in “14L” or “16L”)

Table 4 - PRS Series Spacers (optional accessories)

Spacer Model

Thickness (each)

inches

mm

PRS1

1

25

PRS2

2

51

PRS3

3

76

PRS4 Spacer Set

Set includes PRS1, PRS2 and PRS3 (1 each).

CAUTION:

Never exceed the maximum additional stack

height for your jack model. Refer to Table 5 for additional

information.

Important:

Refer to

Table 5 for maximum

additional stack height

information.

PRS Series Spacer

(see Table 4)

Load Cap

(see Table 6)

PRE Series

Extension

(see Table 3)

Cylinder Rod

Figure 4, Extension and Spacer Installation (typical)

5