INSTALLATION INSTRUCTIONS

serving a separate solid-fuel burning appliance.

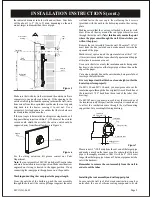

Begin the installation by locating the wall studs on the side

wall of the structure. Find the centerlines between the studs

where you want the unit to be mounted. Refer to the following

illustration (Figure 5) for a side view of how the finished

installation should look. This appliance is certified for

installation on walls which are a maximum of 12” (305 mm)

thick. The vent assembly supplied with the unit will

accomodate walls up to that thickness.

With the template flat and level against the inside wall, mark

the location for the opening for the vent assembly as well as the

location of the two holes for mounting the wall support plate

and the one for the gas supply, if the supply is to be through the

wall. If desired, (and in accordance with all applicable

building and plumbing codes) the gas piping can be brought

into the room through the floor underneath the unit.

Remove the template from the wall and with a long drill, make

a hole in the center of the opening for ventilation all the way

through inside and outside wall. Trace the wall opening in

Cutting the Vent Hole

Location of Furnace

Locating Wall Opening

Note:

The heater must be on an outside wall in the room to be heated.

When choosing a location for the furnace please remember

that the vent cap supplied with the unit must be installed

without alteration, with the exception of cutting the vent tubes

and insulation to length, as directed in these instructions. The

outside vent cap needs to be flush to the wall, so select a

relatively smooth exterior surface.

Since this appliance is a direct vent (balanced flue) design, all

combustion and ventilation air is drawn from outside of the

structure. No special considerations for combustion are

necessary inside the structure. Once you have determined that

the exterior vent will meet the clearances above, you must

locate the heater on the inside wall of the room to be heated.

Begin the installation by locating the wall studs on the inside

wall of the structure. Find the centerlines between the studs

where you want the unit to be mounted.

A full scale template is furnished with the unit which

illustrates the vent and gas supply openings and mounting

holes in their correct locations on the wall.

the figure 4 gives the required dimensions for mounting

the unit, in the event that the template is unusable or lost.

Place the template on the wall so that the vent opening will be

located between the studs and, in the case of the MV 130, for

example, the bracket mounting holes are over the studs (16” /

406 mm, on center). DO NOT CUT THE WALL STUDS IN

ORDER TO INSTALL THE UNIT. Place the bottom edge of

the template directly on the floor or the floor covering such as

carpeting or tile.

Make sure that the location you have selected for the furnace

complies the requirements above before its installation.

This gas appliance must not be connected to a chimney flue

Installing the Unit

3/16” (4.7 mm)

Mounting Holes

D

A

C

21

5/

8

” (

5

5

0

m

m

)

FLOOR

Figure 4

CLEARANCES (cont.)

J=

K=

L=

M=

clearance to nonmechanical air supply inlet to

building or the combustion air inlet to

any other appliance

clearance to a mechanical air supply inlet

clearance above paved sidewalk or paved

driveaway located on public property

clearance under veranda, porch deck, or balcony

CANADIAN INSTALLATIONS

1

US INSTALLATIONS

2

6” (15 cm) for appliances 10,000 Btu/h

(3 kW), 9” (23 cm) for appliances 10,000

Btu/h (3 kW) and

0,000 Btu/h (15 kW)

3 feet (91 cm) above if within 10 feet

(3 m) horizontally

<

>

5

<

clearance in accordance with local

installation codes and the

requirements of the gas supplier

1 In accordance with the current CSA B149.1,

.

Natural Gas and Propane Installation Code

2 In accordance with the current ANSI Z223.1/NFPA 54,

.

3 A vent shall not terminate directly above sidewalk or paved driveaway that is located between two

National Fuel Gas Code

single family dwellings and serves both dwellings.

4 Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides

beneath the floor.

6” (15 cm) for appliances 10,000 Btu/h

(3 kW), 12” (30 cm) for appliances 10,000

Btu/h (3 kW) and 100,000 Btu/h (30 kW)

6 feet (1.83 m)

7 feet (2.13 m)

12” (30 cm)

4

<

>

<

3

Page 8

A

10 1/4” (260 mm)

16” (406 mm)

16” (406 mm)

D

5 1/2” (140 mm)

6 3/4” (171 mm)

8 1/2” (216 mm)

E

6 1/8” (155 mm)

9” (230 mm)

9” (230 mm)

C

4 1/4” (108 mm)

4 1/4” (108 mm)

3 3/4” (98 mm)

MOD

MV 120

MV 130

MV 145

E

MV1XX-1-0603