PILOT FLAME CHARACTERISTICS

MAIN BURNER FLAME CHARACTERISTICS

There will be a short blue inner flame with a much larger

lighter blue secondary flame. The burner flame may have a

yellow tip when hot. See the burner drawing showing the

approximate heights of each part of the flame. Dust in the

combustion air will produce an orange or red flame. Do not

mistake the orange or red flame for an improper yellow flame.

After use, cleaning may be required for the proper flame.

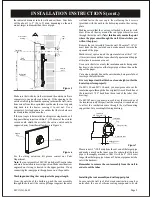

The correct flame will be almost horizontal, blue and will

extend past the thermocouple 1/4" (6 mm). The flame will

surround the thermocouple just below the tip.

On propane (LP-gas) slight yellow might occur where the pilot

flame and burner flame meet.

Natural gas pilots require adjusting when the inlet pressure is

above 5" w.c. (1.25kPa). Turn adjustment screw clockwise to

reduce flame.

Propane (LP-gas) will not require adjusting.

Pilot

Flame must extend

past the thermocouple

Thermocouple

Figure 11

Figure 12

The appliance should be inspected and cleaned before using

each year by a qualified service person.

the following instructions are designed to direct a

qualified technician through the proper periodic maintenance

and repair which may be required throughout the expected life

of this unit.

1. Remove the cover from the unit by removing the two nuts at

the bottom of the unit.

Warning:

NO attempt should be made by the homeowner

to perform these functions.

2. The gas supply should be turned OFF at the shut-off valve in

the supply piping leading to the appliance (if installed), or at

the gas meter or propane/ LP tank.

3. Remove the two screws which hold the unit to the wall

support plate and lift and pull the unit away from the wall.

4. Carefully examine the interior of the vent pipes, both large

and small diameter. If you notice any blockage or

obstruction, clean the pipes.

5. Look inside the openings of the rear of the unit and check for

any foreign materials. Remove any objects which may

block or obstruct the free flow of combustion and

ventilation air. You will only be able to see a portion of the

interior of the unit from this angle.

6. The main burner and pilot burner can be removed from the

unit for cleaning by first loosening the compression fittings

The gas to the unit

should be disconnected so the unit can be removed from

the wall.

that supply gas to both the main burner and pilot. Note:

before removing either the pilot assembly or main burner

assembly be sure to have replacement gaskets on hand.

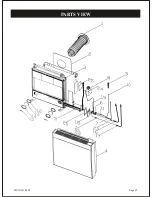

See Figure 13. After unscrewing the gas connection to the

burner and removing the compression nuts, unscrew the

thermocouple from the base of the pilot and remove it from

the pilot assembly. Remove the four screws which hold the

main burner/pilot plate in place, and withdraw the

burner/pilot from the unit. Check the burner/pilot for dirt,

lint, or a black powdery carbon deposit. If any is noted,

brush it off completely using a soft bristled brush, or blow it

MAINTENANCE

Burner flame

Primary flame 1/4” (6 mm) to 1/2” (13 mm)

Secondary flame 4” (102 mm) to 6” (152 mm)

Figure 13

Screws that hold

the main burner/pilot

plate in place

Gas connection

to the burner

Thermocouple

Page 12

MV1XX-1-0603