37410-0-0616

Page 17

OPTIONAL BLOWER INSTALLATION INSTRUCTIONS

Installing blower Using Three-Prong Plug

1. Install furnace according to Installation Instructions and Owner's

Manual.

2. Refer to Drawing for measurements to locate (2) mounting holes

on wall surface above furnace.

On Solid Wall

3. After locating mounting holes, attach (2) #10 x 1 1/2" screws provided

in blower kit into wall. Do not completely tighten screwheads to

wall, leave a 7/16" gap between screwheads and wall.

On Sheet Rock Wall

3. After locating mounting holes, drill (2) 5/16" diameter holes into

wall. Insert the (2) plastic expansion anchors into holes. Insert (2)

#10 x 1 1/2" screws provided in blower kit into (2) plastic expansion

anchors. Do not completely tighten screwhead to plastic expansion

anchors, leave a 7/16" gap between screwheads and plastic

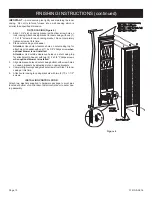

expansion anchors. Refer to Figure 2.

4. At the top of outer casing remove (1) screw from center clearance

hole that attaches outer casing to header assembly. Also, remove

(2) screws that attach bottom of outer casing to inner casing.

5. Pull the outer casing forward approximately 1 inch away from wall

surface.

6. Remove (4) 8 x 3/8" screws that attach blower front to blower

housing.

Caution:

When removing blower front be careful not to damage

motor coil wires. Damaged coil wires will disable blower function.

7. Position blower housing on top of header assembly and route

three-prong cord set between left side of outer casing and inner

casing.

Caution:

Blower cord set routing is important. Cord set should be in

proper location to avoid being overheated. Incorrect routing of cord

set may result in damage to cord set.

8. Replace the outer casing to the wall surface.

9. Attach outer casing to header assembly.

Attention:

The center

clearance hole will not be used. The two outside clearance holes

will be used to attach outer casing to header assembly, (1) screw

from Step 4 and (1) screw supplied in hardware package. Refer

to Figure 1.

Figure 1

10. Attach outer casing to inner casing with (2) screws from Step 4.

11. Align key hole slots on back of blower housing with the (2) screws

attached to wall. Position blower housing flush with wall surface

and on top of outer casing. Complete tightening blower housing

screws from Step 3 to wall.

12. Attach caps and plugs from blower housing and blower front.

13. Attach blower front to blower housing with (4) 8 x 3/8" screws from

Step 6.

14. Installation of optional blower assembly is completed.

Caution

: When installing blower housing onto wall be careful motor

coil is not damaged.

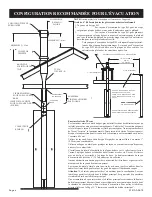

Installing blower With Hard Wiring

1. When facing the wall opening, install 120V electrical outlet junction

box inside wall opening on left wall stud approximately 12 inches

above header plate.

2. Refer to Drawing for measurements to locate access hole for

electrical wiring on wall surface.

3. After locating access hole, drill a 1/2" hole into wall.

4. Route enough field wiring from 120V electrical outlet junction box

through 1/2" access hole in wall for connection to blower housing.

5. Install furnace according to Installation Instructions and Owner's

Manual.

6. Refer to Drawing for measurements to locate (2) mounting holes

on wall surface above the furnace.

On Solid Wall

7. After locating mounting holes, attach (2) #10 x 1 1/2" screws provided

in blower kit into wall. Do not completely tighten screwheads to

wall, leave a 7/16" gap between screwheads and wall.

On Sheet Rock Wall

7. After locating mounting holes, drill (2) 5/16" diameter holes into

wall. Insert (2) plastic expansion anchors into holes. Insert (2) #10

x 1 1/2" screws provided in blower kit into (2) plastic expansion

anchors. Do not completely tighten screwhead to plastic expansion

anchors, leave a 7/16" gap between screwheads and plastic

expansion anchors. Refer to Figure 2.

Figure 2

8. Remove three prong cord set from blower housing.

9. Remove (4) 8 x 3/8" screws that attach blower front to blower

housing.

10. Position blower housing on top of header assembly.

11. Route 120V field wiring into blower housing through cord set hole

on back of blower housing.

12. Refer to wiring diagram to make wiring connections inside blower

housing. Be sure to follow all local and National electrical codes

when making field wiring connections.

13. Align key hole slots on back of blower housing with (2) screws

attached to wall. Position blower housing flush with wall surface

and on top of outer casing. Complete tightening blower housing

screws from Step 7 to wall.

14. Attach caps and plugs from blower housing and blower front.

15. Attach blower front to blower housing with (4) 8 x 3/8" screws from

Step 9.

16. Installation of optional blower assembly is completed.

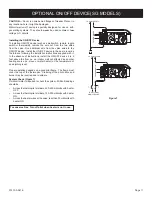

GWTB2W-1 FOR MODELS

GWT-25W, GWT-35W, GWT-50W