TB-6584

Page 6 of 13

© 2016 DESCO INDUSTRIES, INC.

Employee Owned

T. RS-485 Communication Terminal:

Used when

connecting a series of SmartLogs in an RS-485 daisy chain.

Contact the manufacturer

for more information.

U. Relay Terminal:

Can be integrated with electronic door

locks, lights, buzzers, etc. See “Relay Terminal” on page 10

for more information.

V. Clock Configuration Buttons:

See “Configuration” in

the following section for more information.

W. Reset Button:

Press this button to reset the power on

the SmartLog V5™.

X. Ground Jack:

Insert the banana plug end of the

included ground cord to this jack. Connect the ring terminal

end of the cord to equipment ground. This connection will

remove any static charge from the user before the test.

NOTE: Failure to correctly ground the SmartLog V5™ may

result in damage not covered under warranty.

Installation

The following procedures will walk you through the setup and

installation of your SmartLog V5™.

Clock Configuration

NOTE: The Clock Configuration procedure only needs to be

followed when installing multiple SmartLogs.

1. Unscrew the right-hand connection cover, and power the

SmartLog V5™ using the included power supply.

2. The SmartLog will cycle through a self diagnostic

program. The time and date will appear on the screen

when the diagnostics are complete.

3. Press the MENU button six times to enter setup mode.

If the MENU button is not pressed within 20 seconds

after power up, the SmartLog will lockout from setup

mode and require a power reset for another attempt to be

made.

4. Use setup mode to cycle through various settings. Use

the ADVANCE button to change any value and the

ENTER button to move to the next setting.

Ensure that your SmartLog has the following

configurations:

BAUD

9600

PARITY

ODD

SMART LOG ID

00

The SmartLog ID is a two digit field that ranges from

00-63. Each SmartLog must have a unique ID number

should you have several units configured to your system.

DAYLIGHT

DISABLE

PORT EXPAND

YES

DECODE

NO

READER

MAGSTRIPE

5. Press the MENU button to save and exit setup mode.

Tester Configuration

The resistance limits for footwear and wrist strap tests are

controlled by the DIP switches located on the right side of the

SmartLog V5™. Use the following tables for the DIP switch

settings and their corresponding test values.

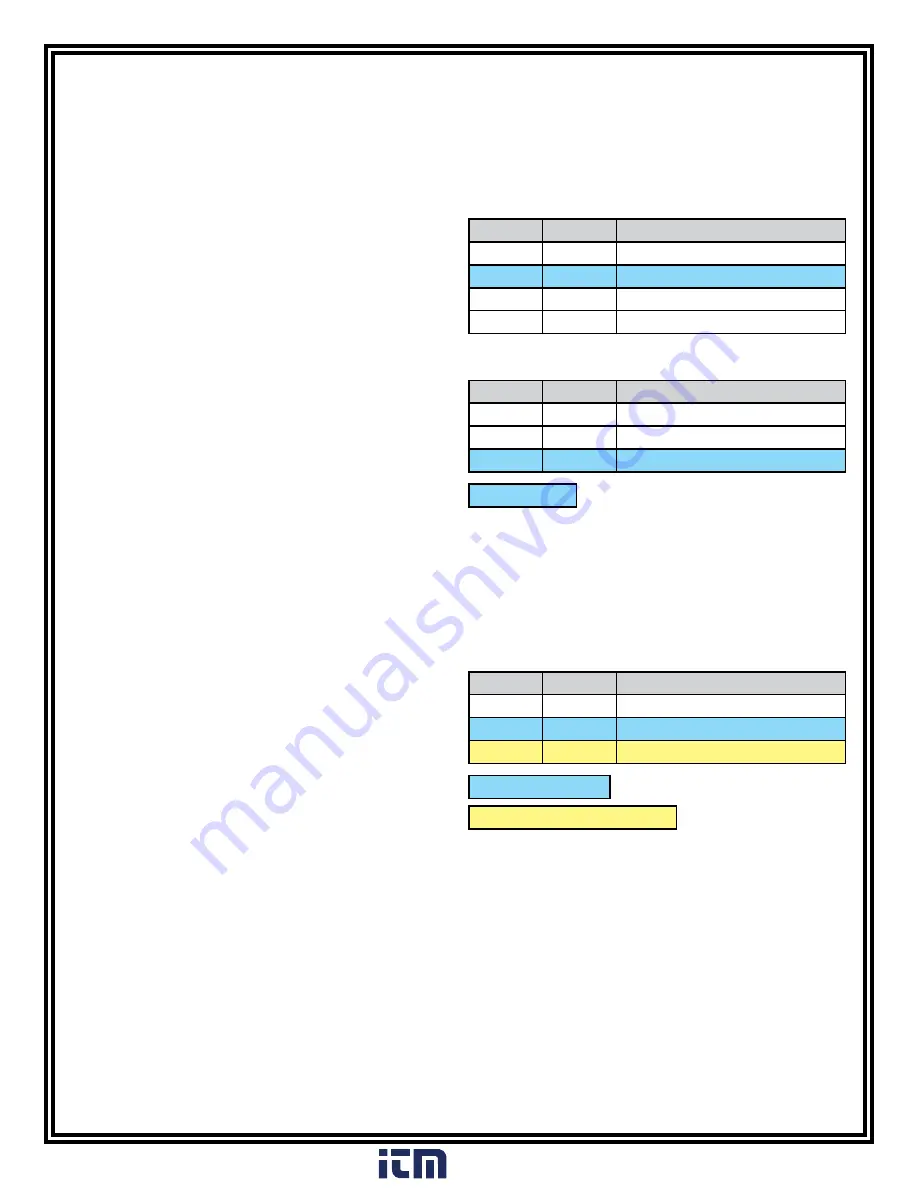

Footwear Resistance

DIP switches 1 and 2 control the HIGH test limit.

Switch 1 Switch 2 HIGH Limit Resistance

ON

ON

10 Megohms (1 x 10

7

)

OFF

OFF

35 Megohms (3.5 x 10

7

)

ON

OFF

100 Megohms (1 x 10

8

)

OFF

ON

1 Gigohm (1 x 10

9

)***

DIP switches 3 and 4 control the LOW test limit.

Switch 3 Switch 4 LOW Limit Resistance

OFF

OFF

footwear test disabled

1

ON

OFF

100 Kilohms (1 x 10

5

)

OFF

ON

750 Kilohms (7.5 x 10

5

)

default setting

***At 1 Gigohm high limit resistance, a dirty foot plate

could result in a false pass. Be sure to keep the foot

plate clean with 99% isopropyl alcohol when using this

setting. This setting is not suitable for relative humidity

greater than 50%.

Wrist Strap Resistance

DIP switches 5 and 6 control the HIGH test limit.

DIP switch 5 must be ON (default setting) for the wrist

strap test to be active. The wrist strap test will be

disabled if DIP switch 5 is set to OFF.

The LOW limit for the wrist strap test is set to 750

Kilohms and cannot be modified by the user.

Switch 5 Switch 6 HIGH Limit Resistance

OFF

OFF

wrist strap test disabled

1

ON

ON

10 Megohms (1 x 10

7

)

ON

OFF

35 Megohms (3.5 x 10

7

)

default USA setting

default Europe & Asia setting

1

EMIT recommends using the TEAM5 Software to

disable wrist strap and footwear tests. TEAM5 can

assign test protocols unique to the operator.

www.

.com

1.800.561.8187