3

PENBERTHY

MODELS GL AND GH GAS OPERATED JET PUMPS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

4 INSTALLATION

Note:

The user should refer to the relevant

technical data sheet or product proposal to

obtain dimensional information for the specific

size and model of jet pump.

Check the exploded view (Figure 3) for the

location of operating, suction and discharge

connections to insure correct hook up.

4.1 Effect of related piping and precautions

1. Penberthy models GL and GH gas operated

jet pumps may be installed and operated in

any position.

2. Jet pumps should be installed with pipe and

fittings which provide minimum resistance

to fluid flow. Pipe line friction losses must

always be a consideration when estimating

jet pump performance.

3. It is recommended that provisions be made

for pressure gauge connections near the

inlet, suction and discharge connections

of the jet pump. If operating difficulties are

encountered at any time, it may become

necessary to install pressure gauges to

identify the problem.

4. Steam must not have over 20°F (-7°C) of

superheat, or performance will differ from

that published in the relevant technical data

sheet or product proposal referred to above.

5. When pumping liquids, suction piping

should be sized so that the velocity of the

liquid does not exceed 4 feet per second.

This is almost always obtained automatically

when the suction line is the same pipe size

as the suction connection.

6. Install a valve in the suction line if it is

desirable to:

a. Prevent contamination of suction fluid by

the motive fluid at start up.

b. Prime a centrifugal pump.

c. Throttle suction flow.

7. When a gas operated jet pump is used to lift

liquids by suction or vacuum, the jet pump

should be located as close to the level of

the liquid as practical. However, any liquid

entrained into the jet pump,

other than water

when using steam as the operating medium

,

may cause the jet pump to stop pumping,

resulting in a possible suction flow reversal.

8. Discharge piping should be sized as short as

possible and with the least number of turns

and restrictions. Discharge piping friction

losses must always be considered when

estimating jet pump performance. Increase

discharge line pipe size if necessary to

minimize loss.

9. Do not impose system piping loads on a

jet pump. The unit is NOT designed to be a

load-bearing fitting.

10. All piping should be clean and free of foreign

materials which could clog the jet pump.

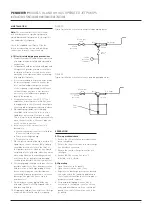

FIGURE 1

Typical installation schematic gas operated pumping gases

FIGURE 2

Typical installation schematic steam operated pumping water

Motive gas

valve

Inlet

Discharge

Motive

pressure

Suction

Suction

pressure

(vacuum)

Check

valve

Motive gas

valve

Suction

Discharge

Motive

pressure

Foot

valve

5 OPERATION

5.1 Pre-operational check

1. Ensure that all installation procedures have

been completed.

2. Ensure that any restrictions in the discharge

line have been removed.

3. Ensure that any discharge line valves are

fully open.

4. Ensure that the suction line valve, if

installed, is fully closed.

5.2 Operating

1. Open the motive valve quickly.

2. Open the suction line valve, if any.

3. Regulate the discharge pressure as desired

to a value within the capability published in

the relevant technical data sheet or product

proposal referred to above.

4. For pump priming applications, when

evacuation is completed, close the suction

valve and immediately start the centrifugal

pump. Then shut off the motive valve to the

jet pump.

Inlet