4

PENBERTHY

MODELS GL AND GH GAS OPERATED JET PUMPS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

6 MAINTENANCE

WARNING

Maintenance should only be undertaken by

qualified, experienced personnel who are

familiar with this equipment and have read and

understood all the instructions in this manual.

DO NOT proceed with any maintenance unless

the jet pump has been relieved of all pressure

or vacuum, has been allowed to reach ambient

temperature and has been drained or purged of

all fluids. Failure to follow these instructions may

cause a sudden release of pressure resulting in

personal injury or property damage.

6.1 Preventative maintenance

The following items should be evaluated

regularly by the user for purposes of

maintenance:

1. Jet pump units for corrosion or debris

build up.

2. Piping and fittings for corrosion or debris

build up.

3. All connections for tightness.

4. Strainers for debris build up.

5. Units for wear.

The user must determine an appropriate

maintenance schedule most suitable for his or

her specific application, upon evaluation of their

own application and the factors stated above.

6.2 Troubleshooting (see Table 2)

TABLE 2 - TROUBLESHOOTING

Problem

Cause

Solution

The suction flow is less than expected

1. Suction piping is too restrictive

1. Remove restriction

2. Discharge pressure is too high

2. Remove restriction

3. Motive fluid pressure is lower than required

3. Increase pressure

4. Suction liquid is at much higher than ambient temperature

4. Lower temperature or size larger jet pump

5. Suction piping leaks

5. Tighten fittings

7 DISASSEMBLY - REASSEMBLY

WARNING

Do not proceed with removal of the jet pump

from connecting piping unless the jet pump has

been relieved of all pressure or vacuum, has

been allowed to reach ambient temperature and

has been drained or purged of all fluids. Failure

to follow these instructions may cause personal

injury or property damage.

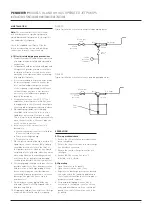

Models GL and GH jet pumps are made up of

two parts (see Figure 3): a nozzle (61) and a

body (11) which are held together by a straight

right hand mechanical thread, closing the face

seal between these parts.

To disassemble the unit, first attach a short

piece of pipe to the suction connection as a

handle, then grip the nozzle flats and rotate in a

counterclockwise direction.

When ready to reassemble the unit, be sure

the seal face of the nozzle and body are free of

foreign material and raised metal due to nicks.

A non-hardening pipe seal compound may

be applied to the threads to promote sealing

further. Thread the body back on to the nozzle

turning in a clockwise direction.

8 DISPOSAL AT END OF USEFUL LIFE

Penberthy jet pumps are used in a variety of

fluid applications. By following the appropriate

federal and industry regulations, the user

must determine the extent of preparation and

treatment the jet pump must incur before its

disposal. A Material Safety Data Sheet (MSDS)

may be required before disposal services accept

certain components.

Metal, glass and polymers should be recycled

whenever possible. Refer to order and

relevant technical data sheets for materials of

construction.