NELSON

™

INSTALLATION

AXPTC125 POWER TEE SPLICE CONNECTION KIT

INSTRUCTIONS

TULSA, OK 74146

TEL 918-627-5530

FAX 918-641-7336

www.nelsonheaters.com

GA-5052 Rev. 3

Sheet 8 of 10

August 2017

Install thermal insulation and protective lagging.

Apply sealant around standoff penetration to

prevent moisture entry.

Leave installation instructions with end user for

future maintenance and/or trouble shooting.

Fill in the blank fields on the label located on the

cover of the junction box as follows:

CIR. NO.

– Electrical circuit heating cable

connected too.

CAT. NO.

– Type of heating cable used

VOLTS

– Operating voltage of heating cable – Max

277VAC

AMPS

– Operating current of heating cable – Max

18A continuous current. 25A for XLT cable.

STEP 10

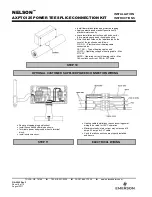

OPTIONAL CUSTOMER SUPPLIED POWER CONNECTION WIRING

Remove stopping plug and locknut.

Install flex conduit and drain as shown.

Terminate power and ground wires to terminal

block.

Install enclosure cover.

STEP 11

ELECTRICAL WIRING

Heating cable installations require incoming power

wiring to be rated for 105ºC operation.

Maximum steady-state current may not exceed 18

amps. 25 amps for XLT cable.

Verify that all connections are properly installed

and secure.