Type Y696

3

chemicals, or other foreign material, point the vent down

or otherwise protect it.

4. To remotely vent the regulator, remove the vent

(key 56) and install obstruction-free tubing or piping into

the 1/4-inch NPT vent tapping. Provide protection on a

remote vent by installing a screened vent cap into the

remote end of the vent pipe.

5. If continuous operation of the system is required

during inspection or maintenance, install a three-valve

bypass around the regulator.

6. Vapor recovery regulators are used to maintain a

constant inlet (blanket) pressure with the outlet flowing

to a system whose pressure is lower than that at the

inlet. The vapor recovery regulators are not intended to

be used as an ASME certified relief device for overpres-

sure protection. They are to be used as part of a gas

blanketing system to control the outflow of blanketing

gas under normal conditions and to collect tank vapors

for the vapor disposal or reclamation system. You

should provide alternate methods of emergency over-

pressure protection.

Startup and Adjustment

To avoid personal injury, property dam-

age, or equipment damage caused by

bursting of pressure containing parts or

explosion of accumulated gas, never

adjust the control spring to produce an

outlet pressure higher than the upper

limit of the outlet pressure range of that

particular spring. If the desired outlet

pressure is not within the range of the

control spring, install a spring of the

proper range according to the dia-

phragm and spring case area section of

the maintenance procedure.

With installation completed, the regulator can be placed

in operation by slowly opening the upstream and

downstream block valves, if used, while using gauges to

monitor pressure.

The regulator has been adjusted at the factory to

provide approximately the pressure requested. The

range of allowable pressure settings is stamped on the

spring casing nameplate. If a pressure setting beyond

the stamped range is required, install a spring with the

desired range by following the procedures for changing

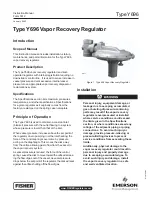

Figure 2. Operational Schematic

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

E0751

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 3. Principal of Operational Schematic

LIQUID

VAPOR PRESSURE

VAPOR RECOVERY

VACUUM SOURCE