For flanged bodies, use suitable line gaskets and approved

piping and bolting practices. Install the regulator in any

position desired

(2)

, unless otherwise specified, but be sure

flow through the body is in the direction indicated by the

arrow on the body.

Note

It is important that the regulator be installed

so that the vent hole in the spring case

is unobstructed at all times. For outdoor

installations, the regulator should be located

away from vehicular traffic and positioned

so that water, ice and other foreign materials

cannot enter the spring case through the vent.

Avoid placing the regulator beneath eaves

or downspouts, and be sure it is above the

probable snow level.

Overpressure Protection

T205 Series regulators have an outlet pressure rating lower

than the inlet pressure rating. The recommended pressure

limitations are stamped on the regulator nameplate. Some

type of overpressure protection is needed if the actual inlet

pressure can exceed the maximum operating outlet pressure

rating. Common methods of external overpressure protection

include relief valves, monitoring regulators, shut-off devices

and series regulation. Overpressuring any portion of the

regulators beyond the limits in the Specifications section

may cause leakage, damage to regulator parts or personal

injury due to bursting of pressure-containing parts.

Regulator operation below the maximum pressure limitations

does not preclude the possibility of damage from external

sources or debris in the line. The regulator should be

inspected for damage after any overpressure condition.

Startup

The regulator is factory set at approximately the midpoint

of the spring range or the pressure requested, so an initial

adjustment may be required to give the desired results.

With proper installation completed and relief valves properly

adjusted, slowly open the upstream and downstream

shutoff valves.

Adjustment

To change the control pressure, perform the

following procedure.

For internal flat circular adjusting screw:

1.

Remove the closing cap (key 22).

2. Use a 25 mm / 1 in. hex rod or flat screwdriver to turn

the adjusting screw (key 35) either clockwise to increase

control pressure or counterclockwise to decrease

control pressure. The regulator will go into immediate

operation. To ensure correct operation, always use a

pressure gauge to monitor the tank blanketing pressure

when making adjustments.

3.

After making the adjustment, replace the closing cap

gasket (key 25) and install the closing cap (key 22).

For external square head adjusting screw:

1.

Loosen the locknut (key 20).

2. Turn the adjusting screw (key 35) either clockwise

to increase control pressure or counterclockwise to

decrease control pressure. Always use pressure gauge

to monitor the tank blanketing gas pressure when

making adjustments.

3. After making the adjustment, tighten the locknut (key 20).

Taking Out of Service (Shutdown)

!

WArNINg

To avoid personal injury resulting from sudden

release of pressure, isolate the regulator from

all pressure before attempting disassembly.

* Recommended spare part

1. Use for optional external square head adjusting screw assembly recommended for 83 to 172 mbar / 1.2 to 2.5 psig, 0.17 to 0.31 bar / 2.5 to 4.5 psig, and 0.31 to 0.48 bar / 4.5 to 7 psig

spring ranges only.

2. Not available for Types T205H and T205HM.

Parts List

Key Description

1 Body

2

Cap Screw

3

Spring Case

4

Lower Casing

5*

Orifice

6

Spring

7

Diaphragm Head

8

Pusher Post

9*

Diaphragm Gasket

10* Diaphragm

11* Body Seal O-

Ring

12* Insert Seal O-ring

13* Disk Assembly

14

Stem

15* Cotter Pin

16

Lever Assembly

17

Machine Screw

18

Guide Insert

19

Upper Spring Seat

(1)

20

Lock Nut

(1)

22

Closing Cap

23

Hex Nut

24

Spring Case Cap Screw

25* Closing Cap Gasket

26

Vent Assembly

Key Description

27

Pipe Plug (Types T205

and T205H only)

30* Stem Seal O-ring

(Types T205M and

T205HM only)

31* Throat Seal O-ring

(Types T205M and

T205HM only)

32

Pitot Tube (Types T205

and T205H)

34

Machine Screw

(Types T205M

and T205HM only)

35

Adjusting Screw

36

Washer

38

Diaphragm Cap Screw

45* Diaphragm Head Gasket

46

Nameplate

47

Drive Screw

48

Flow arrow (not shown)

49

Backup Ring

50

Lower Spring Seat

51

NACE Tag (not shown)

52

Tag Wire (not shown)

54

Diaphragm Head

(not shown)

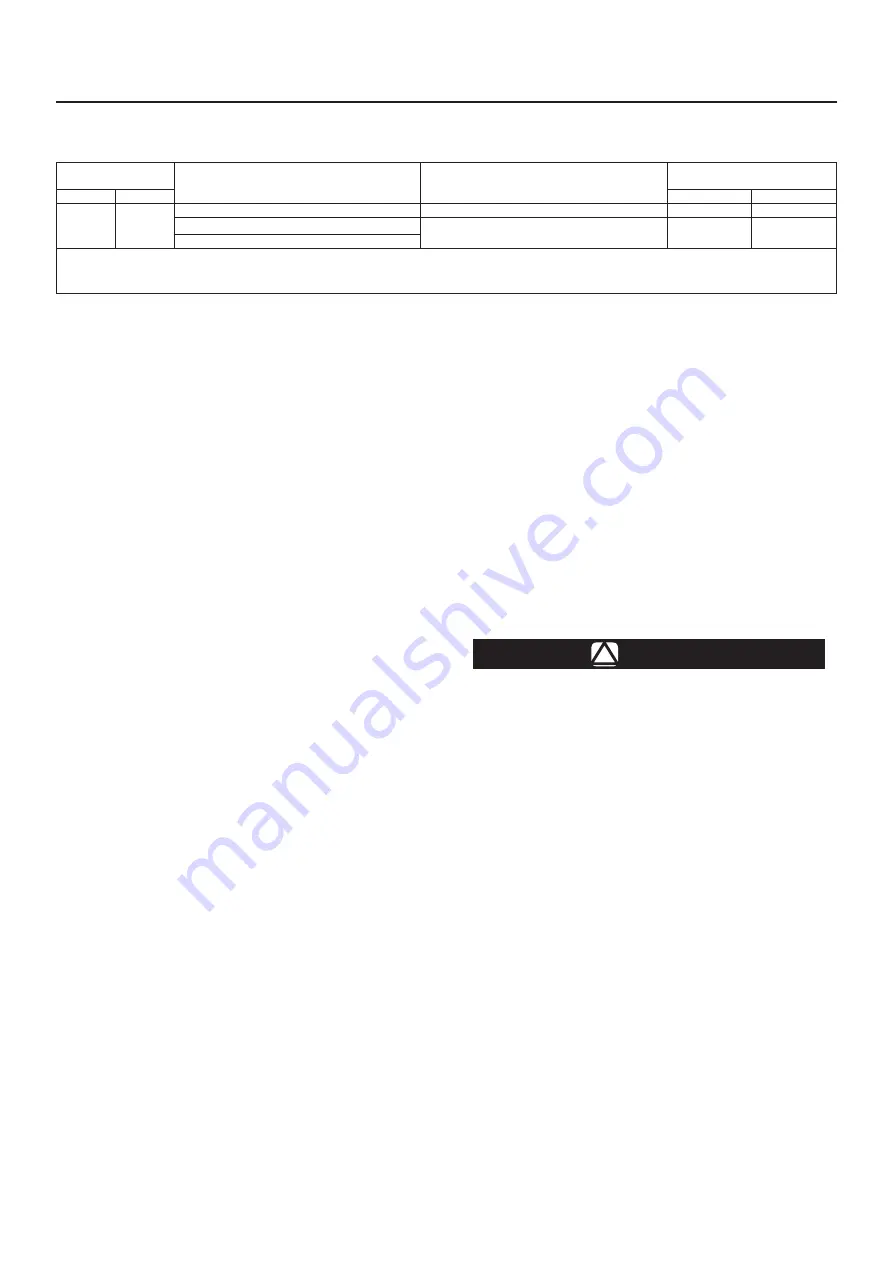

Table 1.

Body Sizes, End Connection Styles and Maximum Allowable Inlet Pressures

BODY SIZE

BODY MATERIAL

ENd CONNECTION STylES

(1)

MAxIMuM AllOWABlE ANd

OPErATINg INlET PrESSurE

dN

In.

bar

psig

20 or 25

3/4 or 1

Gray Cast Iron

(2)

NPT

10.3

150

WCC Carbon Steel

NPT, CL150 RF, CL300 RF or PN 16/25/40 RF

13.8

(3)

200

(3)

CF8M/CF3M Stainless Steel

(4)

1. All flanges are welded. Weld-on flange dimension is 356 mm / 14 in. face-to-face.

2. Not available for Types T205H and T205HM.

3. Inlet pressure is limited to 10.3 bar / 150 psig for Types T205H and T205HM.

4. Pipe nipples and flanges are 316 Stainless steel for flanged body assemblies.

T205 Series

2