Instruction Manual

D103425X012

546NS Transducer

June 2021

14

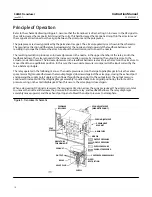

Principle of Operation

Refer to the schematic drawing in figure 5. Assume that the transducer is direct‐acting. An increase in the DC signal to

the coils increases the magnetic field around the coils. This field increases the magnetic strength in the armature and

the magnetic attraction across the air gap between the armature and the pole pieces.

The pole pieces are already polarized by the permanent magnet. The armature polarity is as shown in the schematic.

The magnetic attraction will therefore be downward at the nozzle end and upward at the feedback bellows end,

resulting in a torque that rotates the armature about the fixed torsion rod to cover the nozzle.

The resulting restriction produces an increased pressure in the nozzle, in the upper chamber of the relay, and in the

feedback bellows. The relay responds to the increase in nozzle pressure by increasing the output pressure to the

actuator and control valve. The increased pressure in the feedback bellows creates a force that acts on the armature to

move it back to an equilibrium position. In this way, the new nozzle pressure is compared to the input current by the

force‐balance principle.

The relay operates in the following manner. The nozzle pressure acts on the large top diaphragm to force the center

spacer assembly (mounted between the two diaphragms) downward against the valve plug, closing the exhaust port

and opening the supply port. Supply air then flows through the open port to the output load. The output pressure

continues to increase until the relay diaphragm assembly is pushed back to its original position by the force of the

pressure acting on the small diaphragm. When this occurs, the valve plug is closed again.

When a decreasing DC signal is received, the magnetic attraction across the air gap is reduced. The armature rotates

to uncover the nozzle and decrease the pressure in the nozzle, relay, and feedback bellows. The relay diaphragm

assembly moves upward, and the exhaust port opens to bleed the output pressure to atmosphere.

Figure 5. Transducer Schematic

FEEDBACK

BELLOWS

POLE

PIECES

COIL

ARMATURE

TORSION ROD

EXHAUST

OUTPUT

RELAY

VALVE PLUG

SUPPLY

FIXED

RESTRICTION

CENTER SPACER ASSEMBLY

EXHAUST PRESSURE

SUPPLY PRESSURE

NOZZLE PRESSURE

OUTPUT PRESSURE

NOZZLE

ARMATURE

PERMANENT

MAGNET

ZERO ADJUSTMENT

SPAN ADJUSTMENT

(MAGNETIC SHUNT)

CP4285-A

A1505-3