Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

24

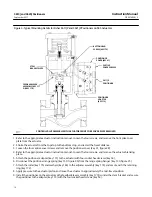

The table in figure 14 and a label inside the positioner cover (key 41, figure 28) recommend flexure adjustment

starting positions for various actuator types. Start with the flexure adjustment set to the recommended starting

distance from the gain adjustment plate, the X dimension in figure 14. To adjust the minor loop gain, proceed as

follows:

1. Unscrew the four captive cover screws and remove the cover (key 41, figure 28).

dimension between the plate and the adjustment.

flexures to increase or decrease the X dimension. Moving the flexure adjustment in the direction of the arrow on the

top flexure (decreasing the X dimension) slows the positioner response. Moving the flexure adjustment in the

opposite direction speeds up the positioner response.

4. Tighten the flexure adjustment screw and check the positioner response. Repeat step 3 if readjustment is required.

5. If this is the only adjustment, replace the cover. If not, continue with the Crossover Adjustment.

20B1277‐E

A3233‐2

GAIN ADJUSTMENT

PLATE

SOCKET HEAD

SCREW (KEY 55)

TOP FLEXURE

(RELAY BEAM

FLEXURE)

FLEXURE

ADJUSTMENT

(KEY 156)

Actuator

”X” Dimension

mm

Inches

1052/20, 2052/1

1051, 1052/30, 33, and 40, 2052/2

1051, 1052/60

1052/70

2052/3

22

24

35

38

37

7/8

15/16

1‐3/8

1‐1/2

1-7/16

1061/30

1061/40

1061/60

1061/80

21

22

24

27

13/16

7/8

15/16

1‐1/16

1061/100

1069/100

29

44

1‐1/8

1‐3/4

585C/25 and 50

585/100

33

1‐5/16

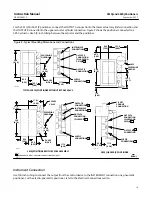

Crossover Adjustment

Perform one or the other of the following procedures, depending on the positioner and actuator type. When finished

with the crossover adjustment, proceed to the zero and span adjustments.

Spring and Diaphragm Actuators (3610J or 3620J Positioners)

Note

Do not perform these steps 1 through 6 if calibrating a 3610JP, 3611JP, 3620JP, or 3621JP positioner. These 6 steps are only

applicable to 3610J and 3620J positioners used on spring and diaphragm actuators.

1. Unscrew the four captive cover screws and remove the cover (key 41, figure 28).

2. If the positioner does not have pressure gauges, connect a pressure gauge to OUTPUT A.

3. Apply supply pressure.

Figure 14. Minor Loop Gain Adjustment