5-8

L3820EA

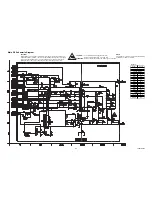

19. Purity Adjustment

Purpose:

To obtain pure color.

Symptom of Misadjustment:

If Color Purity

Adjustment is incorrect, large areas of color may not

be properly displayed.

1. Set the unit facing east.

2. Operate the unit for over 30 minutes before

adjusting.

3. Fully degauss the unit using an external

degaussing coil.

4. Loosen the screw on the Deflection Yoke Clamper

and pull the Deflection Yoke back away from the

screen. (See Fig. 6)

5. Loosen the Ring Lock and adjust the Purity

Magnets so that a red field is obtained at the

center of the screen. Tighten Ring Lock. (See Fig.

5,6)

6. Slowly push the Deflection Yoke toward bell of

CRT and set it where a uniform red field is

obtained.

7. Tighten the clamp screw on the Deflection Yoke.

20. VRS Adjustment

1. Connect Oscilloscope and get the cross hatch

pattern.

2. Adjust the two magnets for VRS adjustment like

the below figure so that the cross hatch pattern

becomes flat.

21. Convergence Adjustment

Purpose:

To obtain proper convergence of red, green

and blue beams.

Symptom of Misadjustment:

If Convergence

Adjustment is incorrect, the edge of white letters may

have color edges.

1. Loosen the Ring Lock and align red with blue dots

or Crosshatch at the center of the screen by

rotating (RB) C.P. Magnets. (See Fig. 7)

2. Align red / blue with green dots at the center of the

screen by rotating (RB-G) C.P. Magnet. (See Fig.

8)

3. Paintlock the C.P. Magnets after adjustment.

Test Point

Adj. Point

Mode

Input

---

Deflection Yoke

Purity Magnet

---

Red Color

Tape

M. EQ.

Spec.

---

Pattern

Generator

See below

Figure

Fig. 5

GREEN

RED

BLUE

Test Point

Adj. Point

Mode

Input

---

C.P. Magnet (RB)

C.P. Magnet (RB-G)

Deflection Yoke

---

Dot Pattern

or

Crosshatch

Tape

M. EQ.

Spec.

---

Pattern Generator

See below

Figure

Fig. 6

Fig. 7

Fig. 8

DY WEDGE

DEFLECTION YOKE

C.P. MAGNET

RING LOCK

SCREW

SCREW

RB-G

RB

PURITY

CRT

COIL

COIL CLAMPER

C.P. MAGNET CLAMPER

B

G

R

R

G

B

C.P. MAGNET (RB)

RB

G

RB

G

C.B. MAGNET (RB-G)