1592023040 XM668D GB r1.1 2011.07.05.doc

XM668D

6/14

second possibility, it can be used only in centralized plants and it is available

only with electronic expansion valve

by selecting [

CrE=Y

] parameter. The third

kind of regulation has been thought to be used with vales called evaporator valves

[

CrE=EUP

], in this configuration the valve is placed at the end of the evaporator. In

any case, the regulation is performed via PI regulator that gives the opening

percentage to the valve.

Standard regulation: [CrE=n]

In this case, the

HY

parameter is the differential for standard ON/OFF regulation. In

this case the

int

parameter is neglected.

Continuous regulation: [CrE=Y]

In this case, the

HY

parameter is the proportional band of PI in charge of room

temperature regulation and we advise to used at least [

HY = 5.0°C/10°F

]. The

int

parameter is the integral time of the same PI regulator. Increasing

int

parameter the

PI regulator become slowly in reaction and of course is true vice versa. To disable the

integral part of regulation you should set [

int=0

].

Evaporator valves: [CrE=EUP]

In this case, the system performs a regulation of the temperature without thinking

about the superheat (in fact the valve is at the end of the evaporator). The

HY

parameter is the proportional band for the temperature regulation and

int

is the

integral time for the regulation. In this situation there is no superheat regulation.

12.3

DEFROST

Defrost starting

In any case, the device check the temperature read by configured defrost probe

before starting defrost procedure, after that:

-

(If RTC is present)Two defrost modes are available through the

tdF

parameter:

defrost with electrical heater and hot gas defrost. The defrost interval is controlled

by parameter

EdF

: (

EdF=rtC

) defrost is made in real time depending on the hours

set in the parameters

Ld1

to

Ld6

in workdays and in

Sd1

to

Sd6

on holidays;

(

EdF=in

) the defrost is made every

idF

time.

-

Defrost cycle starting can be operated locally (manual activation by means of the

keyboard or digital input or end of interval time) or the command can come from

the Master defrost unit of the LAN. In this case the controller will operate the

defrost cycle following the parameters it has programmed but, at the end of the drip

time, will wait that all the other controllers of the LAN finish their defrost cycle

before to re-start the normal regulation of the temperature according to

dEM

parameter.

-

Every time any of the controller of the LAN begin a defrost cycle it issue the

command into the network making all the other controllers start their own cycle.

This allows a perfect synchronization of the defrost in the whole multiplexed

cabinet according to

LMd

parameter.

-

Differential defrost:

Selecting

dPA

and

dPb

probes and by changing the

dtP

and

ddP

parameters the defrost can be started when the difference between

dPA

and

dPb

probes is lower than

dtP

for all

ddP

time. This is useful to start defrost when a

low thermal exchange is detected. If [

ddP=0

] this function is disabled.

-

Defrost ending

-

When defrost is started via

rtC

, the maximum duration of defrost is obtained from

Md

parameter and the defrost end temperature is obtained from

dtE

parameter

(and

dtS

if two defrost probes are selected).

-

If

dPA

and

dPb

are present and [

d2P=Y

]

,

the instrument stops the defrost

procedure when

dPA

is higher than

dtE

temperature and

dPb

is higher than

dtS

temperature.

At the end of defrost the drip time is controlled through the

Fdt

parameter.

12.4

FANS

CONTROL WITH RELAY

The fan control mode is selected by means of the

FnC

parameter:

C-n

= running with the solenoid valve, OFF during the defrost;

C-Y

= running with th1e solenoid valve, ON during the defrost;

O-n

= continuous mode, OFF during the defrost;

O-Y

= continuous mode, ON during the defrost.

An additional parameter

FSt

provides the setting of temperature, detected by the

evaporator probe, above which the fans are always OFF. This can be used to make

sure circulation of air only if his temperature is lower than set in

FSt

.

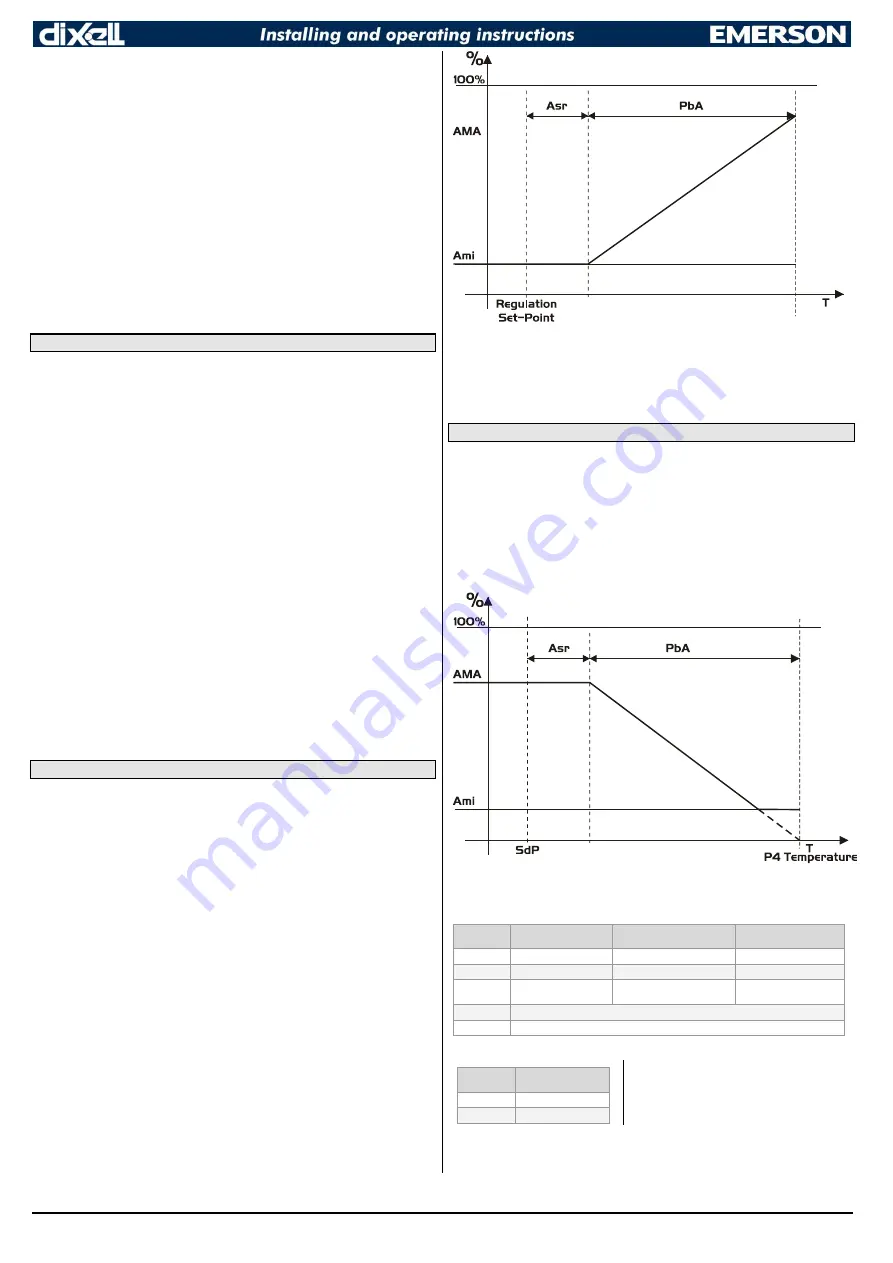

CONTROL WITH ANALOG OUTPUT (if present)

The modulating output [

trA=rEG

] works in proportional way (excluding the first

AMt

seconds where the fans speed is the maximum. 10seconds is the minimum value).

The regulation set point is relative to regulation set point and is indicated by

ASr

, the

proportional band is always located above [

SET+ASr

] value and its value is

PbA

.

The fans are at minimum speed

AMi

when the temperature read by fan probe is

[

SET+ASr

] and the fan is at maximum speed (

AMA

) when the temperature is

[

SET+ASr+PbA

].

12.5

ANTI SWEAT HEATERS

The anti-sweat heater regulation can be performed with on board relay (if

oA6=AC

)

or with the analog output (if present by setting

trA=AC

). However the regulation can

be performed in two ways:

Without real dew-point information: in this case the default value for dew-

point is used (

SdP

parameter).

Receiving dew-point from

XWEB5000

system: the

SdP

parameter is

overwritten when valid value for dew-point is received from XWEB. In

case of XWEB link is lost,

SdP

is the value that will be used for safety.

The best performance can be obtained using probe 4. In this case, the regulation

follows the chart:

Probe 4 should be placed on the showcase glass

. For each cabinet can be used

only one probe 4 (P4) sending its value to the others section that are connected to

the LAN.

HOW TO WORK WITH PROBE 4 THROUGH THE LAN:

Param.

XM6x8D_1

Without probe 4

XM

with

probe 4

XM

Without probe 4

Adr

n

n + 1

n + 2

LCP

LCP = n

LCP = Y

LCP = n

P4C

LAN or not

connect the probe

P4C = NTC, PtC or

PtM

LAN or not connect

the probe

trA

trA = AC if the device has the analog output

oA6

oA6 = AC if the device will use the AUX relay for regulation

HOW TO WORK WITHOUT PROBE 4:

Param.

XM6x8D

Without probe 4

P4C

nP

AMt

% of ON

In this case, the regulation is performed by

switching on and off the auxiliary relay on a

60 minutes time base. The ON time will be

the

AMt

value, so that the relay will be ON for

AMt

minutes and OFF for

[60-AMt]

minutes.

In case of P4 error or if P4 is absent the output is at

AMA

value for the

AMt

time then

the output is at 0 value for the time [

255–AMt

] time performing a simple PWM

modulation.