11

ANDERSON GREENWOOD

TYPE 91 AND 94 PILOT OPERATED SAFETY RELIEF VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

6 LEAK TESTING ASSEMBLY

6.1 General

The complete valve assembly should be leak

tested for internal and external leaks using a

pressure equal to 10% and 90% of set.

6.2 Internal leak test

Nozzle

Use a piece of wide masking tape to cover

the lower part of the main valve outlet, taped

across the opening 2” to 3” (50 to 76 mm) high.

Pour in enough water to cover just the base of

the nozzle. If bubbles are detected, the nozzle

seal is leaking.

Main seat

Pour in enough water to just cover the bottom

of the bellows and seat plate.

If bubbles are detected, the main seat is

leaking. Nozzle or seat may be damaged or

the bellows may not be seating squarely on

the nozzle. Improper bellows seating may

be due to incorrect assembly of cap to body.

Refer to Section 2

6.3 External leak test

Following the internal leak test, check for

external leakage by applying leak test solution

to all joints and seals. Tighten bolts or fittings

as required.

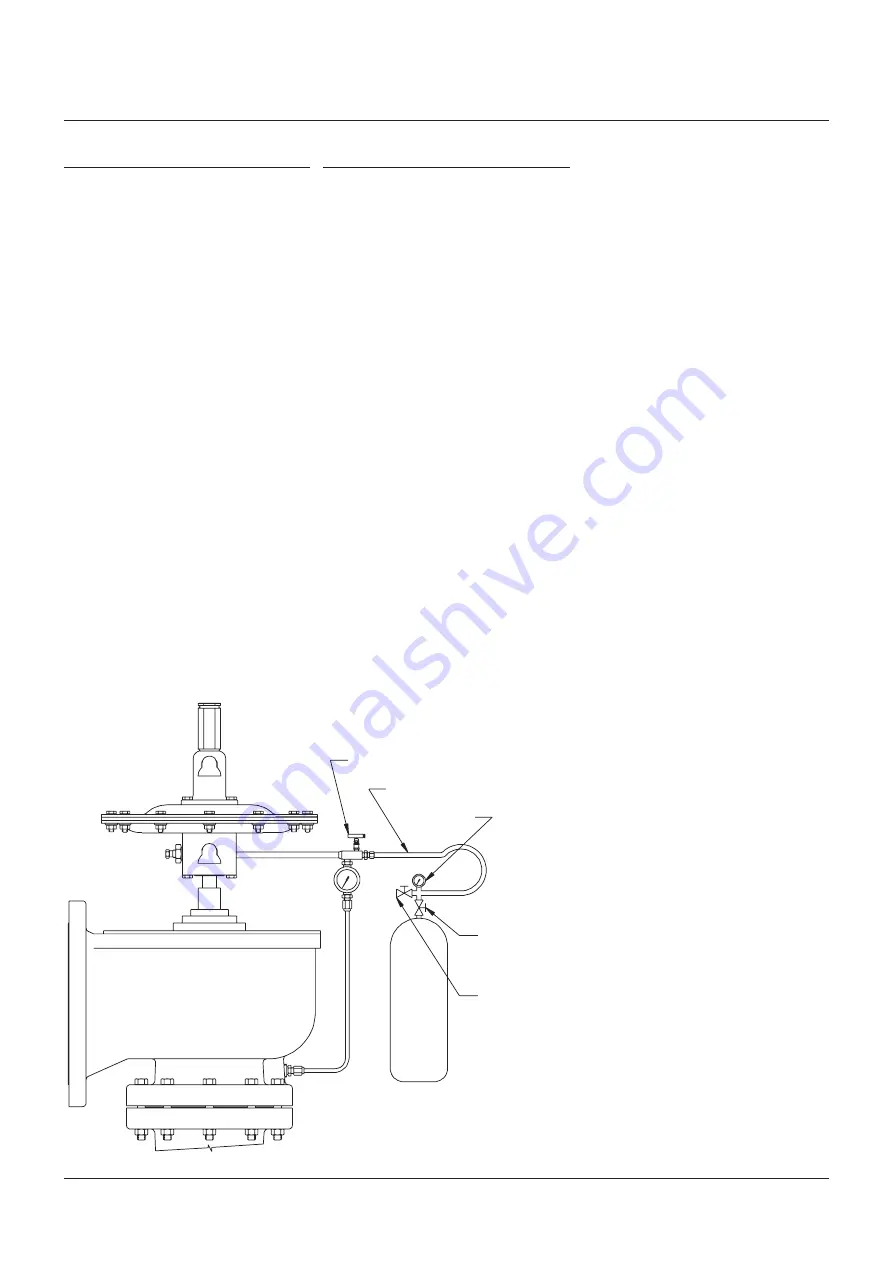

7 PILOT SET PRESSURE FIELD TEST PROCEDURE

7.1 General

The pilot set pressure can be checked in

the field by applying an external test pressure

to the pilot through the field test hand valve as

shown in Figure 9.

NOTE

If the process pressure at the time of test is less than

approximately 30% of the pilot set pressure, the main

valve will not open. If the process pressure is greater

than 30% and the main valve must remain closed,

temporarily replace the pilot exhaust vent with an

orifice plug having an orifice diameter of .040”/.060”

(1.02 mm/1.52 mm). This orifice must be removed

on completion of field testing as it prevents the main

valve from opening.

7.2 Procedure

1. Connect test gas bottle as shown in Figure 9.

2. Close vent valve “C”.

3. Open field test valve “B”. Test gauge will

read process pressure.

4. Open block valve “A” SLOWLY to increase

pressure until pilot “pops”. The set pressure

will be the pressure indicated on the test

gauge at the time of pop.

5. To remove test set up, close valves “A” and

“B”, open valve “C”.

FIGURE 9

Field test valve “B”

Flexible hose

Block valve “A”

Block valve “C”

Nitrogen

bottle

Test gage