PFA, BGT · Edition 03.11

22

6 .3 Wiring

Integrate module subracks BGT in the equipotential bonding

system.

6 .3 .1 Safety-related control signals

Signals from the safety interlocks and digital input are trans-

ferred independently of the bus communication by separate

cables.

The purge signals can be transferred via the bus communica-

tion or by a separate cable.

6 .3 .2 EMC

To achieve a high immunity of the system against electro-

magnetic interference radiation, a shielded data cable must

be used. The shield must be connected to protective earth

on both sides using wide-area shield clips that ensure good

conductivity.

In addition, it must be ensured that all cables leading to and

from the PFA be installed as far away as possible from cables

emitting strong fields (e.g. frequency converter cables).

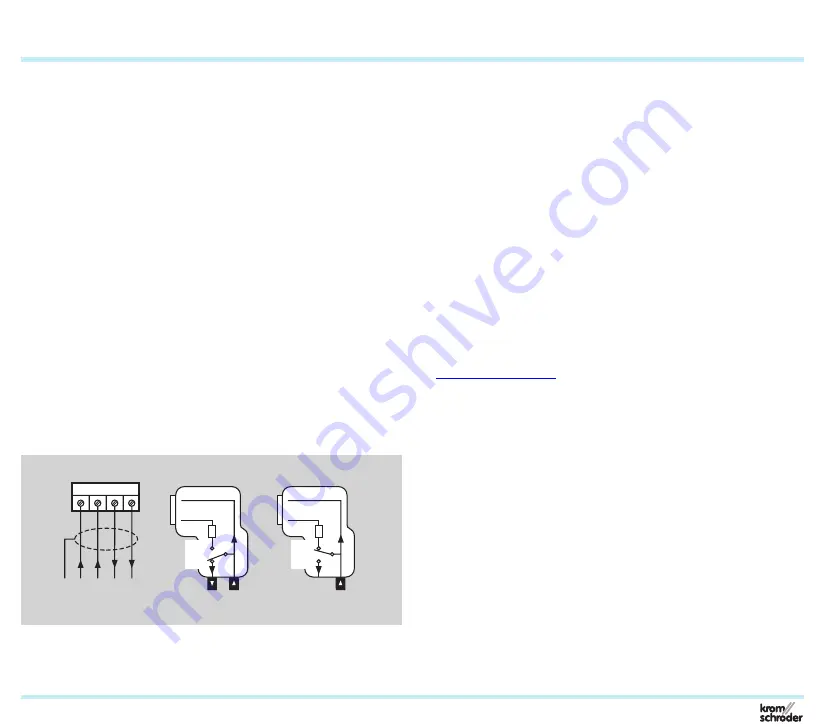

6 .3 .3 PROFIBUS plug connector

PROFIBUS-DP

A B A’ B’

OFF

ON

OFF

ON

Data cables A and B must not be reversed.

The power supply for the bus terminator is provided by the

PFA. The bus terminator can be connected in the PROFIBUS

plug connector.

Ensure an equipotential bond between the different slaves

and masters.

Bibliography

– PROFIBUS Specification, EN 50170 Vol. 2 (version 1.0).

– Installation Guideline for PROFIBUS DP/FMS, available

from the Profibus User Organization (PUO).

– PROFIBUS Technology and Application, Order No.: 4.001,

available from the PUO.

– M. Popp, The New Rapid Way to PROFIBUS DP, a textbook

for system operators.

– M. Popp, PROFIBUS DP Principles, Tips and Tricks for Us-

ers.

– www.profibus.com

6 .4 Manual operation

For emergency operation, the time-limited manual mode can

be deactivated.

The PFA is delivered with manual mode pre-set to a time limit

(parameter 34 = 1).

Project planning information