Technical Manual Cold Storage Controllers TKP / TKC x130 - x140

Page 11

Real Time Clock

The built-in real time clock is buffered for a period

where mains voltage is switched off (3 years up to

softw.vers. 6.9, appr. 10 days from softw.vers. 7.00).

Date and Time can be set on the 'mode page'.

Factory set is a GMT +01:00 ('timezone offset'=

60 min.), which is valid for mid europe. If the con-

troller is used in other zones, the values can be

readjusted.

Summer/Winter Time (Daylight Saving Time)

Switching / Time Zones

An automatic summer / winter switching (parameter

„

summer/ winter

“) considers the current EU-rules

from 1996 (EU 96), but it can also switched off or

set as necessary.

Variable Time Zones

By parameter "

timezone offset

" the summer/winter

time switching can be adapted as necessary.

"

summerOn month

" (fact.set: march, 3rd)

The month before summertime begins

"

summerOn day

"

(fact.set: 0, sunday)

The day of the week where summertime begins

"summerOn

x-day

"

(fact.set: 5, last sunday)

The day no. x in the month set with

"summerOn day

"

"

summerOn hour

"

(fact set: 2, (2:00 am))

The hour of the beginning of the summertime

"

summerOff month

" (fact.set: october, 10th)

The month of the end of the summertime

"

summerOff day

"

(fact.set: 0, monday)

The day of the week where summertime ends

"

summerOff x-day

"

(fact.set: 5, last sunday)

The day no. x in the month set with

"

summerOff day

"

"

summerOff hour

"

(fact.set: 2, 2:00 am)

The hour of the end of the summertime

All time settings are preset in winter time

.

Analog Output

The controller contains an analog output which

can be used for regulation or to provide a remote

display with an actual value image. The signal

is available as a DC-Voltage or a DC-Current-

Signal.

Parameter „

analog value

“ (actual page) shows the

current output signal as a %-part of the selected

range, "

analog function

" (assignment page) de-

termines the behaviour of the output:

Test functions (output delivers fixed values only)

0V

= voltage = 0V, current = 0 mA

4mA

= voltage = 2V, current = 4 mA

10V/20mA

= voltage = 10V, current = 20mA

Transmission of actual values to remote displays

or similar

act.img 0-10V

=

The outputs provide an image of the value of

refrig.sensor 1.

voltage: -50°C = 0V, +100°C = 10V

current: -50°C = 0mA, +100°C = 20mA

act.img 4-20mA

=

The outputs provide an image of the value of

refrig.sensor 1. .............

voltage: -50°C = 2V, +100°C = 10V

current: -50°C = 4mA, +100°C = 20mA

Control with the analog output signal (PI-con-

trol)

PID-T1 0-10V

=

This PID-controller with 0-10V DC-signal is

assigned to cooling circuit 1. The output signal

represents an addition of the components

P, I, D and T1.

PID-T1 4-20mA

=

This PID-controller with 4/20mA-signal is

assigned to cooling circuit 1. The output signal

represents an addition of the components

P, I, D and T1.

PID-T1 10-0V

=

PID-controller like above, but with inverted

voltage output (rising temperature = falling

voltage).

PID-T1 20-4mA

=

PID-controller like above, but with inverted

4/20 mA-output (rising temperature = falling

current)

To adapt the controller to the process use the

following parameters:

" PID propor band"

.....situated symmetrically

to '

setpoint Ch 1

'

" PID integr time"

.......integral time (I-part)

" PID attack time"

.......derivative time (D-part)

" PID delay"

............actuator response time

(T1-part)

How to affect the analog output manually

For certain operations it might be usefull to affect

the output signal manually. Therefore the function

„

analog value

“ (assignment page) can be assigned

to one of the digital inputs.

Applying mains phase to a configured digital input

the analog output will be forced to the value (in %)

that is programmed by „

opto->analogout

“ (setpoint

page). So e.g. a connected valve drive will be set

to a specific position.

"

function Opto. x

" (Assignment Page)

= configuration of the digital (OK) input for

this function

"

opto->analog val.

" (Setpoint Page)

= value of the output signal in %/V/mA, if

the digital (OK) input has been activated

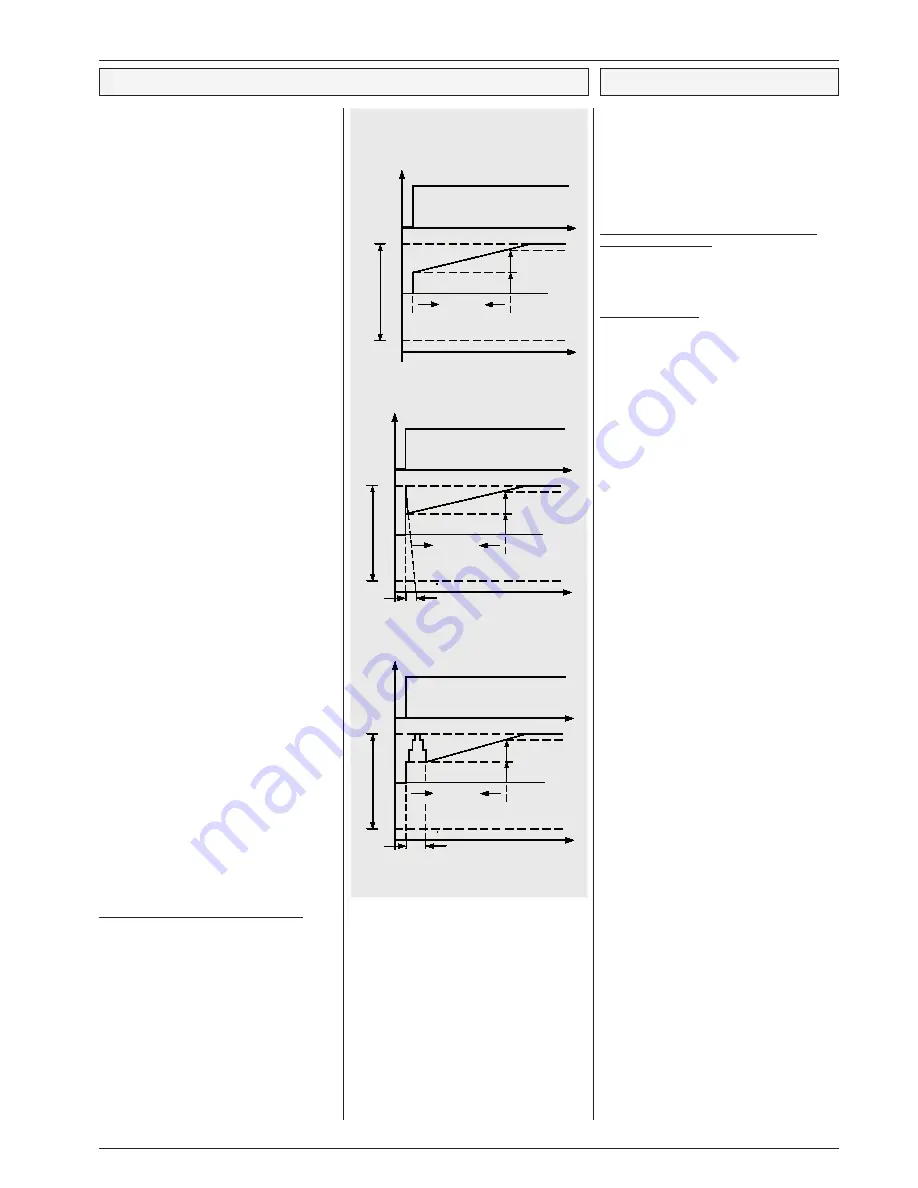

PI-control, D and T1-parts de-activated

PID-control, T1-part de-activated

PID-control, with T1-low-pass filter

Control Characteristic

P ID

integral tim e

pr

op

or

tio

na

l b

an

d

m in.

ou

tp

ut

se

tp

oin

t-

de

via

tio

n

m ax.

5V resp. 12m A

P -part

t

I-part

t

t

P ID attack tim e

P ID

inte g ral tim e

pr

op

or

tio

na

l b

an

d

m in.

ou

tp

ut

5 V re sp . 1 2 m A

P -p art

I-p art

se

tp

oin

t-

de

via

tio

n

m ax.

t

t

P ID d e lay

pr

op

or

tio

na

l b

an

d

m in.

ou

tp

ut

5 V re sp . 1 2 m A

P ID

inte g ral tim e

P -p art

I-p art

se

tp

oin

t-

de

via

tio

n

m ax.

t