22

MECHANICAL ADJUSTMENT

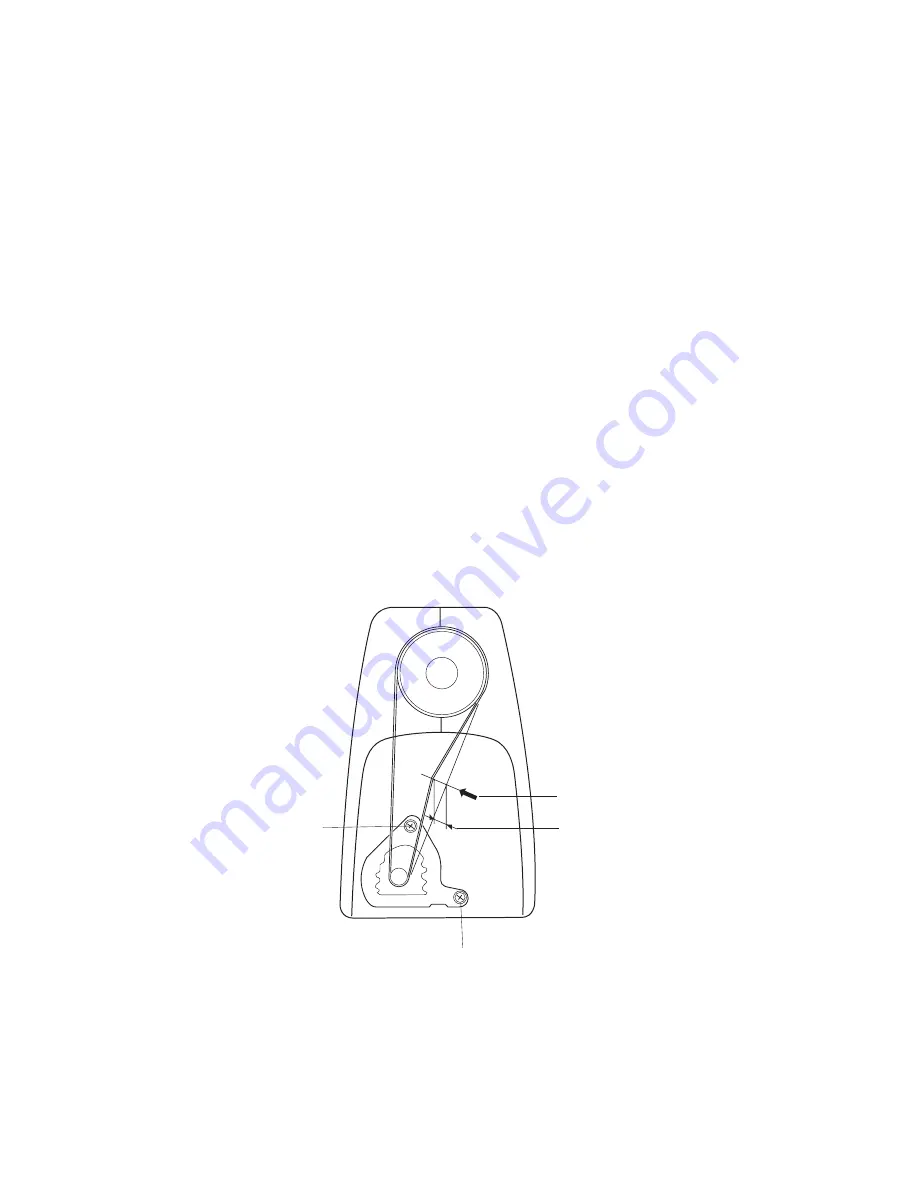

MOTOR BELT TENSION

To check:

1. Improper belt tension may cause noise, overload of motor, slow running or motor belt jumping.

2. The belt deflection should be 7mm - 9mm when pressing the middle of the motor belt with

approximately 300 grams of pressure.

Adjustment procedure:

1. Remove the belt cover (See page 4).

2. Loosen the setscrews (A) and (B).

3. Move the motor up or down to adjust the deflection about 7mm - 9mm.

4. Tighten the setscrews (A) and (B).

5. Attach the belt cover.

300g Load

Deflection 7-9mm

Setscrew (B)

Setscrew (A)