18

0420 Roto-Jet

Flexshaft breakage near the machine.

• Radius of flexshaft is too sharp. Position machine horizontally and at right angle to the tubes

being cleaned. (See “Operation” section)

• Flexshaft is too short for the length of tube being cleaned causing too sharp a radius for

proper operation of the flexshaft. Call Elliott to obtain the proper length

Flexshaft breakage near the cleaning device.

• Flexshaft is allowed to exit the far end of the tube being cleaned causing “Whipping” of the

flexshaft. Measure and mark flexshaft casing with tape to prevent “over-travel” of flexshafting

when cleaning. (See “Operation” section)

• Flexshaft is being forced through a tube blockage. Reduce the rate of feed on the flexshaft

and allow cleaning device additional time to clear the blockage. (See “Operation” section)

Flexshaft coils up when cleaning device is inserted into the tube.

• Check the internal diameter of the tube (Elliott Tube Gauge is recommended) past the expand-

ed portion at the tube opening. Verify the working diameter of the cleaning device being used.

• Reduce the feed rate of the flexshaft and allow more time for the cleaning device to remove

deposits.

• Check for internal enhanced (rifled) surface under the deposit layer. Some cleaning devices

are not designed to clean this type of surface.

• Check for sharp bends or pinch points in the flexshaft.

• Check for proper water flow through the flexshaft. (See “Operation” section)

How to repair broken flexshafts.

• See pages 22 & 23 for use of W900-00.

Summary of Contents for Roto-Jet 0420

Page 2: ......

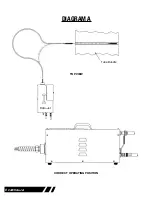

Page 8: ...8 0420 Roto Jet DIAGRAM A Tube Bundle Roto Jet TOP VIEW CORRECT OPERATING POSITION...

Page 19: ...0420 Roto Jet 19 NOTES...

Page 23: ...0420 Roto Jet 23...

Page 25: ......

Page 26: ......