15

EN

Operating and assembly instructions RDF

www.elektror.com

9016315 01.20/12

• Other standards and regulations must be observed

depending on the application.

• Blower feet and consoles must be designed only for the

respective blower’s own weight.

• Cover the open air intake and discharge with protective

grilles according to DIN EN ISO 13857.

• Ensure that the motor has adequate ventilation.

Permitted ambient temperatures with:

Standard model with Elektror motor and a rated voltage of

50 Hz or 60 Hz:

• Ambient temperature -20°C to +60°C

Note!

The rated e

ffi

ciencies and the e

ffi

ciency classes

of the motors are given as per IEC 60034-2-1 for

operation at an ambient temperature of 25°C.

As per IEC 60038 Elektror motors are generally

designed for an extended voltage range of ±10%.

However, the stated e

ffi

ciency relates to the rated

voltage, i.e., the extended tolerance is not taken

into account.

Special voltages, multi-voltage motors, models suitable for

frequency converters, FUK models, devices with UL ap-

proval, devices with Aircontrol and other motor makes:

• Ambient temperature -20°C to +40°C

• Voltage tolerance ±5% (For exceptions, see „4.2 Fre-

quency converter operation“)

• The drive motor ventilation system must not be a

ff

ected

by the installation situation.

Minimum distance to the blower cover (for the intake of

cooling air)

Drive power

Minimum distance

to the blower cover

[mm]

[inches]

≤

1.5 kW

34

1.34

> 1.5 kW

53

2.09

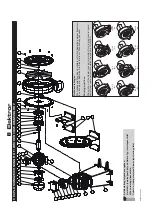

3.3 Electrical connection

Note!

The work described in this section may only be

performed by a quali

fi

ed electrician. Connect ac-

cording to the wiring diagram placed in the termi-

nal box complying with relevant local regulations.

Three-phase or a.c. motors can be used as drive motors.

In the appliance designation, the letter D stands for three-

phase a.c. and the letter E for single-phase a.c.

• The drive motor must be protected using a motor overload

switch (this does not apply to frequency converter oper-

ated appliances). Where appliances are frequency-

converter-operated, the existing temperature sensor (PTC

resistor sensor) or temperature switch (normally closed

contact) must be connected to the converter and evalu-

ated.

• The safety earth terminal can be found in the terminal box.

• Install Electrical ON/OFF switches that can be locked as

maintenance / repair switches.

• Suitable electrical controlling must ensure the blower runs

long enough to clear the line system of any residual media

and avoid its blockage.

• Check that the mains voltage corresponds to the voltage

speci

fi

ed on the nameplate.

Note!

The following information should also be ob-

served when operating the drive motor with a

frequency converter:

• Only motors must be used on the frequency

converter that are marked on the rating plate with

the option “/FU”, “suitable for use with a frequen-

cy converter” or that were ordered and con

fi

rmed

as “suitable for use with a frequency converter”.

• The frequency converter supply voltage must

only be a maximum of 400 V without the motor

fi

l-

ter. Appropriate measures such as a motor

fi

lter to

protect the motor must be installed on the motor

terminals with higher frequency converter supply

voltages, longer lines and/or if the pulse voltages

are exceeded (max. 1000 Vpk for drive motors up

to 0.75 kW, maximum 1300 Vpk for drive motors

larger than 0.75 kW) Please contact the converter

supplier in this case. If a motor

fi

lter is included

in the delivery, this must be installed between

the converter and the motor. Please ensure that

there is su

ffi

cient space in the switch cabinet and

take into account the installation and assembly

requirements in the operating instructions of the

frequency converter/motor

fi

lter manufacturer.

• The maximum cable length between the mo-

tor and switch cabinet frequency converter (e.g.

Lenze Vector, Omron MX2 and Omron RX) must

not exceed 20 m. Maximum cable lengths of up to

3 m are permitted with Kostal INVEOR frequency

converters installed close to the motor and up to

10 m with Lenze MOTEC frequency converters.

Further information on wall mounting close to the

motor can be found in the original operating and

assembly instructions of the respective frequen-

cy converter manufacturer. The electrical con-

necting cables between the motor and frequency

converter in the above cases must be suitable

shielded cables, laid using the shortest route and

without clamping and plug-in connections and

connected correctly at both sides.

• The shielding braid in the connecting cables

must be connected fully, continuously and on

both sides, i.e. to the frequency converter and

motor, and at low resistance and permanently to

protective earthing systems or the main earthing

bus bar. Suitable EMC cable glands must be used

for this on the motor side and also on the INVEOR

wall mounting plate, if necessary.

• It is important to ensure that the solid con-

nection of the device to the protective earthing

system or several suitable earthing lines is at low

resistance and permanent for blowers installed

with electrical insulation (e.g. through vibration

dampers, compensators, insulated pipes, etc.) for

frequency converter operation.

For further information about EMV compliant installation refer

to the operating and assembly instructions of the frequency

converter’s manufacturer.

3.3.1 Con

fi

guration for three-phase current blowers

Warning!

Danger due to loose or improperly tightened con-

nections!

Improperly tightened and loose connections

cause electric shocks,

fi

res, property damage and

personal injuries!

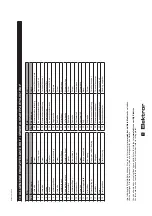

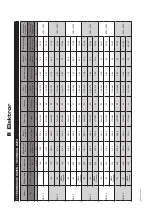

Check for loose connections and tighten in

accordance with the tightening torques in the fol-

lowing table.