15/38

Problem

Check if …

If not, action to do

the top heating element is absor-

bing current with the Multimeter

(approx. 4amps)

replace the upper plate kit

cabling between terminal block

and the board (connector 5) is

connected

connect the wires

the board is not giving power to the

heating elements through the relay

(voltmeter in connector 5 of the

board, 208 V - 230V for CE version)

replace the board

The bottom plate temperature is not

reaching the temperature setting

cabling of the bottom plate to the

board, connector 4 is connected on

position 4 on the power board.

connect the wires

the probe connector INF is connected

in position INF on the board ( lum-

berg black connector.

Connect the connector INF on the

board

the bottom heating element is ab-

sorbing current with the Multimeter

(approx. 4amps)

replace the heating element of the

bottom plate

the board is not giving power to

the heating elements through the

relay (voltmeter in connector 4 of

the board)

replace the board

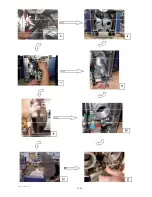

The lid doesn’t latch

The lid never latch

the handle reaches the right posi-

tion to the electromagnet

remove all obstacles and/or check

for mechanical frictions

the electromagnet and/or the

washer are dirty

make a proper cleaning

if the handle magnets are in place

replace the handle

the handle pins are blocked

try to unblock or replace the handle

screw of the washer is tight

readjust the latching system

cables of the electromagnet and

magnetic detectors are connected

(Connector 10)

connect the wires

electromagnet is working by a continuity

test from the connector 10

change the electromagnet

from connector 10 there is nominal

voltage when closing the lid

replace the board if the power

supply is suitable

magnetic detectors are working by

a continuity test from the connectors

14/15 (by closing the lid)

readjust or change the magnetic

detectors

the bimetallic sensors (CLK1 and

CLK2) are working by a continuity

test from the pins of the connector

3 (from the two left and the two right

contacts)

change the bimetallic sensor failed

KS1 is working by visually checking

if the indicator move from the initial

position and the power coming in

reconnect the wires or replace the

contactor

the lid doesn’t latch after some

cycles but restart to latch after

a while

there is enough free clearance for

the airfl ow from the exhaust pipes in

the rear of the machine

give the clearance according to the

installation diagram

HSPP tech GB 03 09

No

No

No

Yes

Yes: Check ...

No

Summary of Contents for HSG Panini

Page 1: ...Service Manual GB 07 2009 HSG Panini Service manual ...

Page 2: ...2 2 50mm 50mm 7 5 190mm ...

Page 3: ......

Page 4: ......

Page 11: ...7 38 Explanation on software settings EU Version U207 ...

Page 12: ...8 38 Explanation on software settings US Version U202 U208 ...

Page 28: ...24 38 HSPP tech GB 03 09 ADJUST THE SPRINGS ...

Page 29: ...25 38 HSPP tech GB 03 09 ...

Page 30: ...26 38 ...

Page 31: ...27 38 5 9 CHANGE THE GAS SPRING ...

Page 32: ...28 38 ...

Page 33: ...29 38 ...

Page 41: ...37 38 ...

Page 43: ......

Page 49: ...Vue éclatée Couvercle Cover exploded view Explosionszeichnung Haube F HSPP FR 03 09 ...

Page 51: ...Esploso coperchio Despiece tapa Sprängskiss lock H HSPP FR 03 09 ...

Page 53: ...Vue éclatée Articulation Hinge exploded view Explosionszeichnung Gelenk J HSPP FR 06 09 ...

Page 55: ...Esploso articolazione Despiece articulación Sprängskiss Rotation L HSPP FR 06 09 ...

Page 59: ...Vue éclatée Electrique Electric exploded view Explosionszeichnung Elektrik P HSPP FR 03 09 ...

Page 61: ...Esploso elettronica Despiece electricidad Sprängskiss elektronik R HSPP FR 03 09 ...

Page 64: ......