2007-10 SOI/DT-mdm FCPD-dp Quality-fz

52/59

599 70 32-47

NO

NO

NO

YES

EA1: Drum positioning system (DSP) faulty (top-loaders)

EA1

No signal or discontinuous signal from the sensor for more than 10 seconds during actioning

of the motor to position the drum

EA1

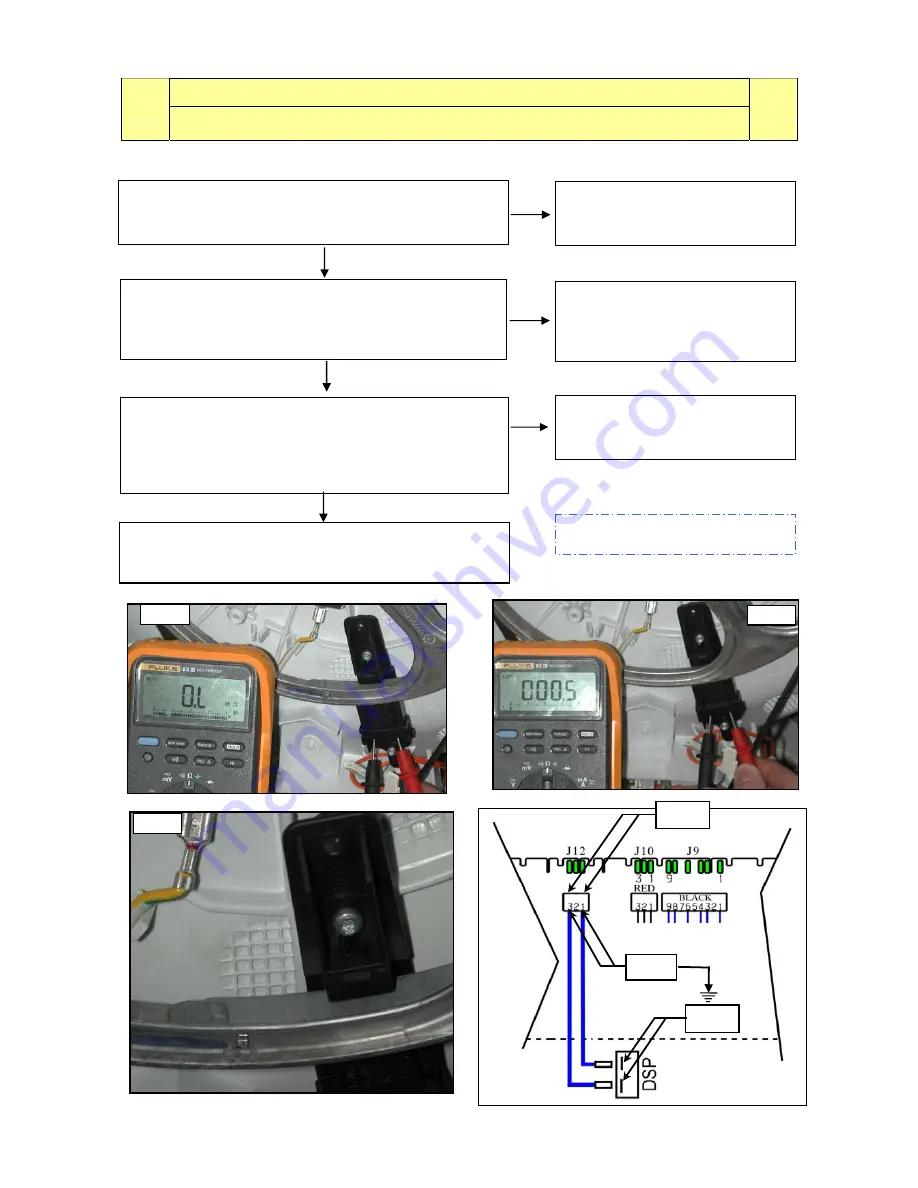

Tests to be performed:

YES

Is the drive belt OK? Is the pulley OK? Is the ferrite plate

positioned correctly?

(fig. 20)

Replace the belt/pulley and restart

the diagnostic cycle to check for

further alarm conditions.

If there are traces of burning on the

circuit board, refer to page

59

Remove the connector and measure directly on the

sensor: - circuit closed when on the normal section of the

pulley

(fig.18)

- circuit open when on the ferrite plate

(fig.19)

.

Is the sensor efficient?

Replace the positioning sensor and

restart the diagnostic cycle to check

for further alarm conditions.

YES

Replace the connector and measure across J12-1 and

J12-3 on the wiring connector: when the drum is rotated,

the circuit should open and close. Check for leakage to

ground across the same terminals.

Is the wiring OK?

Check/replace the wiring and restart

the diagnostic cycle to check for

further alarm conditions.

Start the diagnostic cycle (

phase 9

). If alarm EA1

reappears, replace the circuit board and restart the

diagnostic cycle to check for further alarm conditions.

fig. 18

fig. 19

fig. 20

Circuit

board

∞

Ω

0/

∞

Ω

0/

∞

Ω