16

Installation manual

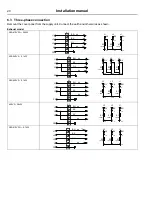

5.2

Fresh air

For maximum efficiency and the shortest possible drying time, it is important to ensure that fresh air is able to enter

the room from the outside in the same volume as that is blown out of the room.

To avoid draught in the room it is important to place the air inlet behind the machine.

The area of the air inlet opening is recommended to be five times the size of the exhaust pipe area. The area of the

inlet opening is the area through which the air can flow without resistance from the grating/slatted cover.

The resistance in the grating/slats on the air inlet cover panel should not exceed 10 Pa (0.1 mbar).

5 x A

A

5 x A

Condense model

Exhaust model

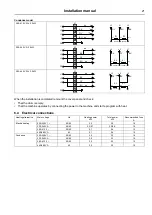

Note!

Gratings/slatted covers often block half of the total fresh air vent area. Remember to take this into account.

5.2.1

Exhaust duct

• Only rigid or flexible metal duct should be used for exhausting.

• Plastic ducting is not to be used.

• Recommended material for exhaust is galvanized steel.

• The duct is not to be assembled with screws or other fastening means that extend into the duct and catch lint.

• The exhaust air should not be vented into a wall, a ceiling, or a concealed space of building.

• The exhaust duct must lead clear of the building as condensation may cause frost damage to the building.

• The exhaust duct must lead to the outdoors.

• The exhaust duct must be placed in such a way that it is protected on the outside.

• The exhaust duct must be smooth on the inside (low air resistance).

• The exhaust duct must have gentle bends.

Summary of Contents for Lagoon TD6-6

Page 2: ......

Page 4: ......

Page 27: ......

Page 28: ...Electrolux Professional AB 341 80 Ljungby Sweden www electroluxprofessional com ...