factory reset - default parameters loading procedure

Sometime, e.g. when you re-configure an instrument previously used for other works or from other people or

when you have made too many errors during configuration and you decided to re-configure the instrument, it

is possible to restore the factory configuration.

This action allows to put the instrument in a defined condition (the same it was at the first power ON).

The default data are those typical values loaded in the instrument prior to ship it from factory.

To load the factory default parameter set, proceed as follows:

1. Press the

button for more than 5 seconds. The upper display will show

PASS

while the lower display

shows

0

;

2. using

and

buttons set the value

-481

;

3. Push

button;

4. The instrument will turn Off all Leds for a few seconds, then the upper display will show

dFLt

(default) and

then all Leds are turned ON for 2 seconds. at this point the instrument restarts as for a new power ON.

The procedure is complete.

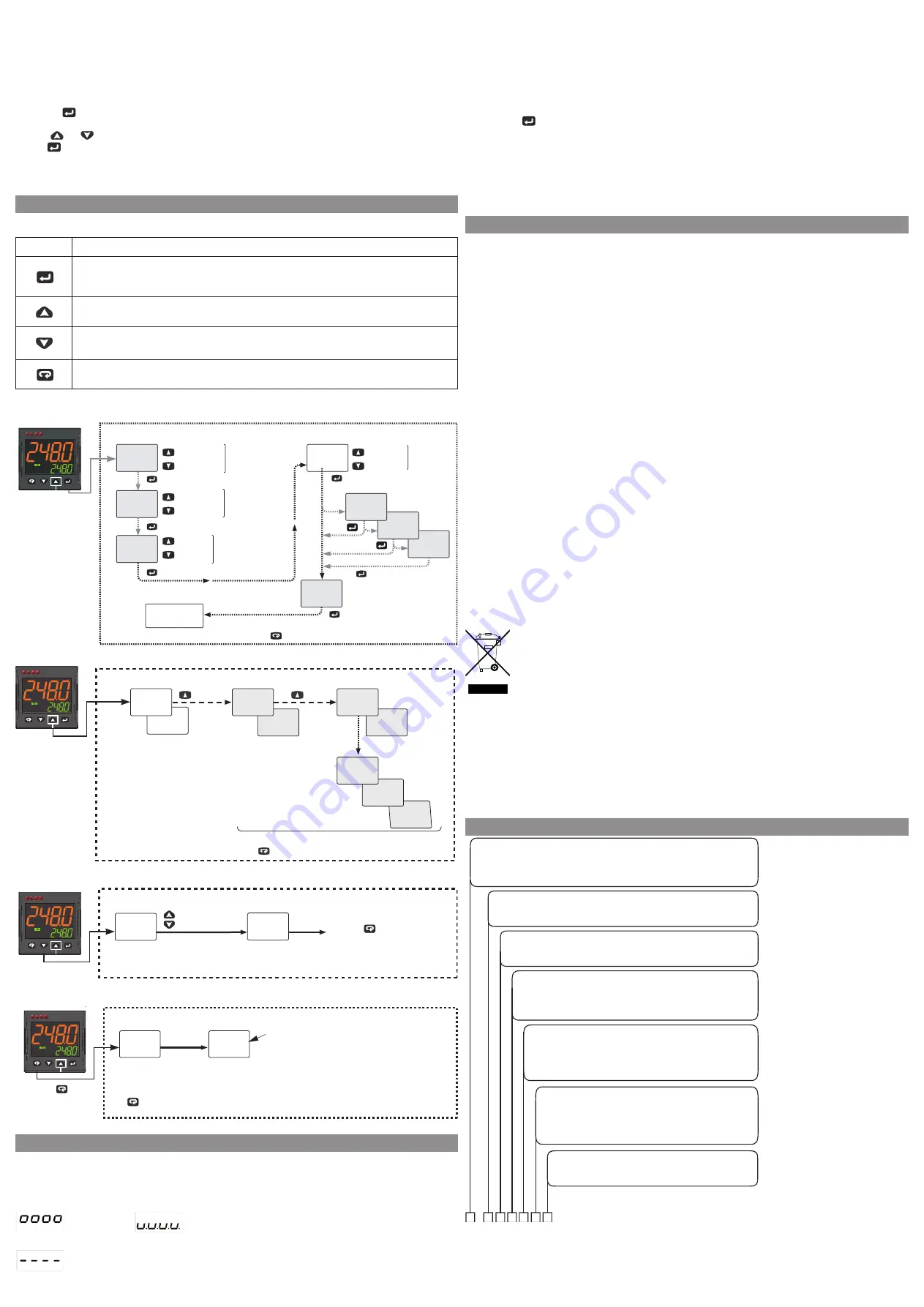

5. OPeraTIVe MOdeS

Keyboard function when the instrument is in auto mode

Key

Operator Mode

access to:

- Operator commands (Timer, Setpoint selection ...)

- Parameters

- configuration

access to Operator additional information (Output value, running time ...)

accesso to Set Point

Start programmed function with

usrb

parameter (autotune, auto/Man, Timer ...)

Operator commands

run

tr.st

248.0

sp

Confirm/Next

Confirm/Next

Confirm/Next

Confirm/Next

Operator Command

Increase

Decrease

run

: Start

hold

: Hold

res

: Reset

Active

Set Point

selection

1

a.sp

If more than

1 Set Point

active

(

nsp

> 1)

Confirm/Next

1

st

SP

value

change

If timer

activated

(

tr.F

)

250

AL1

If AL1 is active

Back to the

first parameter

To return to the Normal Mode, press the key for 3 seconds or wait for the 10s timeout

run

: Start

hold

: Hold

res

: Reset

run

pr.st

Confirm/Next

If program

activated

(

pr.F

)

sp4

nsp

> 1

nsp

> 2

nsp

> 3

340.0

225.0

sp3

120.0

sp2

additional information

t45.2

248.0

h854

248.0

C045

248.0

Additional Information

Output Value %

(e.g. heating = 35%,

cooling = 45%)

Program

Segment

If active

To return to the Normal Mode, press the key for 3 seconds or wait for the 10s timeout

H035

248.0

s1.00

248.0

r1.00

248.0

d854

248.0

U854

248.0

Heating

Cooling

Worked time

(days)

Worked time

(hours)

Power (kW)

or Energy (Wh)

Program/Timer

remaining time

P04.8

248.0

Soak

Ramp

Timer

Program

Set Point change

Press the key (3 s) or wait

for the 10s time out to

store the new Set Point

and return to Normal Mode

Increase value

Decrease value

Operative

Set Point

Changed

operative

Set Point

248.0

sp

250.0

sp

Set Point Change

running the Tuning functions

Press the key

for 3 s

Auto-tune

started

Auto-tune

in progress

tunE

248.0

248.0

248.0.

Note:

The key could be assigned by the user to other functions using the

Usrb parameter

setting

Dot flashes while the Smart TUNE is in progress

Smart TUNE

is a fast and fully automatic procedure that can be

started in any condition, regardless the deviation

from SP. The controller selects automatically the

best tune methodand computes the optimum

PID parameters.

Smart TUNE Start

6. errOr MeSSaGeS

Out of range signals

The instrument points out, on the upper display, the OVer-raNGe and uNder-raNGe conditions using the fol-

lowing indications:

Over-range

under-range

The sensor break will be signalled as an out of range:

Note: When an over-range or an under-range is detected, the alarms operate as in presence of the maximum

or the minimum measurable value respectively.

To check the out of span error condition, proceed as follows:

1. check the input signal source and the connecting line.

2. Make sure that the input signal is in accordance with the instrument configuration.

Otherwise, modify the input configuration (see section 4).

3. If no error is detected, send the instrument to your supplier to be checked.

List of possible errors

eraT fast auto-tune cannot start. The measure value is too close to the set point.

Push the

button in order to delete the error message.

ouLd Overload on output 4. The message shows that a short circuit is present on Out 4 when it is used as ou-

tput or transmitter power supply. When the short circuit disappears the output restarts to operate.

Noat auto-tune not finished within 12 hours.

ereP Possible problem in the instrument memory. The message should automatically disappear, if the error

persists, send the instrument to your supplier.

rone Possible problem of the firmware memory. If this error is detected, send the instrument to your supplier.

errt Possible problem of the calibration memory. If this error is detected, send the instrument to your supplier.

7. GeNeraL NOTeS

Proper use

every possible use not described in this manual must be consider as a improper use.

This instrument is in compliance with

eN 61010-1 “Safety requirements for electrical equipment for measure-

ment, control and laboratory use”; for this reason it could not be used as a safety equipment.

Whenever a failure or a malfunction of the control device may cause dangerous situations for persons, thing

or animals, please remember that the plant has to be equipped with additional safety devices.

eL.cO. S.r.l. and its legal representatives do not assume any responsibility for any damage to people, things

or animals deriving from violation, wrong or improper use or in any case not in compliance with the instru-

ment’s features.

declaration of conformity and Manual retrieval

eLKM43 is a panel mounting, class II instrument. It has been designed with compliance to the european direc-

tives.

all information about the controller use can be found in the engineering user Manual available on the down-

load area of our website www.elco-italy.com .

The declaration of conformity is available for free on request by our web-ticketing support service on our

website.

Maintenance

This instrument does not requires periodical recalibration and it have no consumable parts so that no particular

maintenance is required.

Sometimes it is advisable to clean the instrument.

1. SWITcH THe eQuIPMeNT Off (power supply, relay output, etc.).

2. using a vacuum cleaner or a compressed air jet (max. 3 kg/cm

2

) remove all deposits of dust and dirt which may

be present on the case and on the internal circuits being careful not to damage the electronic components.

3. To clean external plastic or rubber parts use only a cloth moistened with:

z

z

ethyl alcohol (pure or denatured) [c

2

H

5

OH] or

z

z

Isopropyl alcohol (pure or denatured) [(cH

3

)

2

cHOH] or

z

z

Water (H

2

O).

4. Make sure that there are no loose terminals.

5. Before turning ON the instrument make sure it is perfectly dry.

6. apply the power supply to the instrument.

disposal

The appliance (or the product) must be disposed of separately in

compliance with the local standards in force on waste disposal.

Warranty

This product is under warranty against manufacturing defects or faulty materials that are found within 12

months from delivery date. The warranty is limited to repairs or to the replacement of the instrument.

The tampering of the instrument or an improper use of the product will bring about the immediate withdrawal

of the warranty effects.

In the event of a faulty instrument, either within the period of warranty, or further to its expiry, please contact

our our support team through the web-ticketing service on our website.

The return policy will be communicated once the request will be accepted and is also available on the “Sales

condition”.

8. Order cOde

Model

ELKM43

= Controller

ELKM43T

= Cont timer

ELKM43P

= Cont timer + programmer

Power supply

240

= 100... 240 VAC

EV

= 24…240 VAC-VDC

Analogue input + Digital input DI1 (standard)

C

= J, K, R, S, T, PT100, PT 1000 (2 fili), mA, mV, V

E

= J, K, R, S, T, NTC, PTC, mA, mV, V

Output 1

A

= 0/4...20 mA, 0/2...10V

R

= Relais SPST 4A (resistive load)

S

= VDC forSSR

Output 3

-

= Not available

3R

= Relais SPST 2 A (resistive load)

3S

= VDC forSSR

3M

= Relè SPST 2 A (servomotor drive)

Serial communications

-

= TTL Modbus

S

= RS485 TTL Modbus

Output 2

-

= Not available

2R

= Relais SPST 2 A (resistive load)

2S

= VDC for SSR

2M

= Relais SPST 2 A (servomotor drive)

Note: add “W” after the product name for white coloured display led’s

Note: for servomotor drive, both Output 2 and Output 3 codes must be selected as “M”