i.d.a

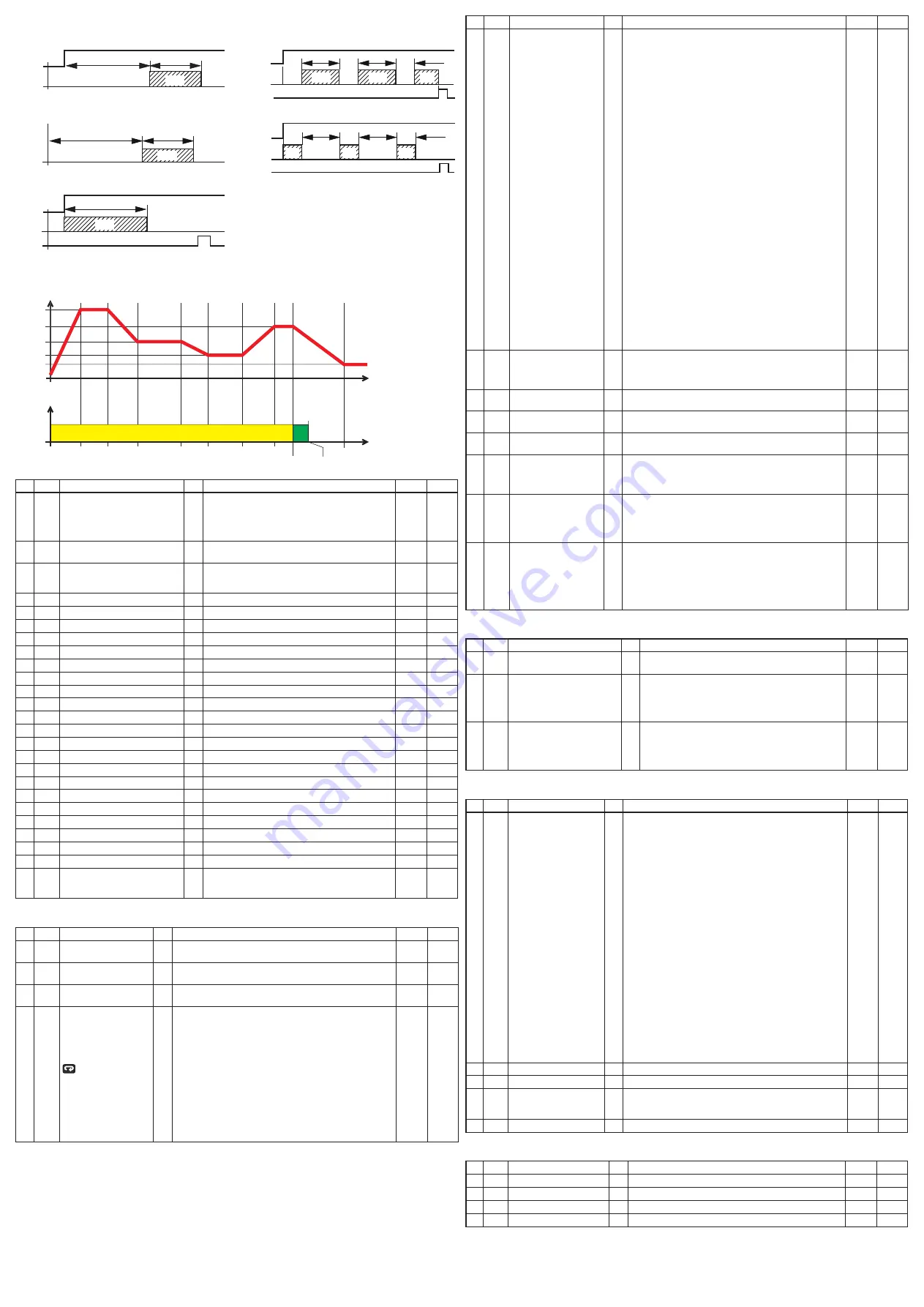

Delayed ON at Start command

i.up.d

Delayed ON at Power ON

i.d.d

At Start command

i.p.l

Asymmetrical oscillator with start in OFF

i.L.p

Asymmetrical oscillator with start in ON

Start

OUT

ON

off

Tr.t1

Tr.t2

off

OUT

PWR ON

ON

off

Tr.t1

Tr.t2

off

Start

OUT

Reset

ON

Tr.t1

off

Start

OUT

Reset

ON

off

Tr.t2

ON

off

Tr.t1

Tr.t1

Tr.t2

ON

off

Tr.t1

Tr.t2

Start

OUT

Reset

ON

off

Tr.t2

off

Tr.t1

Tr.t1

Tr.t2

off

Tr.t1

Tr.t2

ON

ON

PWR ON

PWR ON

Timer Types

(selected by

tr.f

) (option)

]

PRG Group - Programmer function parameters

Time

SPx

Status

Temperature

OFF

Pr.

e

= SPAt

Pr.S1

Pr.S4

Pr.S2

Pr.S3

Prog.

END

prg.1

prt.1

prg.3

prt.3

prg.4

prt.4

prg.2

prt.2

Program RUN

Start

Program Step

no. Par.

description

dec.

Values

default Notes

93 Pr.f

Program action at power up

0

none Programmer not used;

S.uP.d Start at power up with a first step in stand-by;

S.uP.S Start at power up;

u.diG Start at run command detection only;

u.dG.d Start at run command with a first step in stand-by.

none

94 Pr.u Time unit of the soaks

2

hh.nn

Hours and minutes;

nn.SS

Minutes and seconds.

hh.nn

95 Pr.e

Instrument behaviour at the end of

the program execution

0

cnt continue;

SPat

Go to the set point selected by SPat;

St.by

Go to stand-by mode.

SPat

96 Pr.et Time of the end program indication 2

from 0.00 (off) to 99.59 (inf) minutes and seconds off

97 Pr.S1 Set point of the first soak

dP from SPLL to SPHL

0

98 Pr.G1 Gradient of the first ramp

1

0.1... 999.9 engineering unit/minute (inf = Step transfer) inf

99 Pr.t1 Time of the 1

st

soak

2

0.00... 99.59 (time unit of the soaks)

0.10

100 Pr.b1 Wait band of the 1

st

soak

dP 0 (off)/1... 9999 (e.u.)

off

101 Pr.e1 events of the 1

st

group

2

00.00... 11.11 (

0

= event Off;

1

= event ON)

00.00

102 Pr.S2 Set point of the 2

nd

soak

dP Off or from SPLL to SPHL

0

103 Pr.G2 Gradient of the 2

nd

ramp

1

0.1... 999.9 engineering unit/minute (inf = Step transfer) inf

104 Pr.t2 Time of the 2

nd

soak

2

0.00... 99.59 (time unit of the soaks)

0.10

105 Pr.b2 Wait band of the 2

nd

soak

dP 0 (off)/1... 9999 (e.u.)

off

106 Pr.e2 events of the 2

nd

group

2

00.00... 11.11 (

0

= event Off;

1

= event ON)

00.00

107 Pr.S3 Set point of the 3

rd

soak

dP Off or from SPLL to SPHL

0

108 Pr.G3 Gradient of the 3

rd

ramp

1

0.1... 999.9 engineering unit/minute (inf = Step transfer) inf

109 Pr.t3 Time of the 3

rd

soak

2

0.00... 99.59 (time unit of the soaks)

0.10

110 Pr.b3 Wait band of the 3

rd

soak

dP 0 (off)/1... 9999 (e.u.)

off

111 Pr.e3 events of the 3

rd

group

0

00.00... 11.11 (

0

= event Off;

1

= event ON)

00.00

112 Pr.S4 Set point of the 4

th

soak

dP Off or from SPLL to SPHL

0

113 Pr.G4 Gradient of the 4

th

ramp

1

0.1... 999.9 engineering unit/minute (inf = Step transfer) inf

114 Pr.t4 Time of the 4

th

soak

2

0.00... 99.59 (time unit of the soaks)

0.10

115 Pr.b4 Wait band of the 4

th

soak

dP 0 (off)/1... 9999 (e.u.)

off

116 Pr.e4 events of the 4

th

group

0

00.00... 11.11 (

0

= event Off;

1

= event ON)

00.00

117 Pr.St Program status

0

reS

Program reset;

run

Program start;

HoLd

Program hold.

reS

]

PAn Group - Operator HMI

no. Par.

description

dec.

Values

default Notes

118 PaS2 Level 2 password

(limited access level)

0

off (Level 2 not protected by password);

1... 200.

20

119 PaS3 Level 3 password

(complete configuration) 0

3... 200

30

120 PaS4 Level 4 password

(cOde configuration level) 0

201... 400

300

121 uSrb

button function

during ruN TIMe

none No function;

tune

auto-tune/self-tune enabling. a single press (longer than 1

second) starts the auto-tune;

oPLo Manual mode. The first pressure puts the instrument in

manual mode (oPLo) while a second one puts the instrument

in auto mode;

aac

alarm acknowledge;

aSi

alarm reset;

chSP Sequential set point selection;

St.by Stand by mode. The first press puts the instrument in stand by

mode while a second one puts the instrument in auto mode;

Str.t

Timer run/hold/reset;

P.run Program run;

P.reS Program reset;

P.r.H.r Program run/hold/reset.

tune

no. Par.

description

dec.

Values

default Notes

122 diSP display management

none Standard display;

Pou

Power output;

SPf

final set point;

Spo

Operative set point;

aL1

alarm 1 threshold;

aL2

alarm 2 threshold;

aL3

alarm 3 threshold;

Pr.tu - during a soak, the instrument shows the soak elapsed time;

-

during a ramp the display shows the operative set point.

at program end, the instrument alternately displays

P.End

and the measured value;

- When no program is running, the instrument shows the

standard display;

Pr.td

- during a soak, the instrument shows the soak remai-

ning time (count down);

-

during a ramp the display shows the operative set point.

at program end, the instrument alternately displays

P.End

and the measured value;

- When no program is running, the instrument shows the

standard display;

P.t.tu When the programmer is running, the display shows

the total elapsed time. at program end, the instrument

alternately displays

P.End

and the measured value;

P.t.td When the programmer is running, the display shows the total

remaining time (count down). at program end, the instru-

ment alternately displays

P.End

and the measured value;

ti.uP

When the timer is running, the display shows the timer

counting up. at count end, the instrument alternately

displays

t.End

and the measured value;

ti.du

When the timer is running, the display shows the timer

counting down. at count end, the instrument alternately

displays

t.End

and the measured value;

Perc Percent of the power output used during soft start (when the

soft start time is equal to infinite, the limit is always active

and it can also be used when ON/Off control is selected);

PoS

Valve position (servomotor control).

0

123 di.cL display colour

0

The display colour shows the actual deviation (PV - SP);

1

display red (fix);

2

display green (fix);

3

display orange (fix).

0

124 ade

deviation for display colour

management

1... 999 (e.u.)

5

125 di.St display Timeout

2

off (display always ON);

0.1... 99.59 (mm.ss).

off

126 fiLd

filter on the displayed

value

1

off (filter disabled);

from 0.0 (off) to 20.0 (e.u.).

off

128 dSPu Instrument status at power

ON

aS.Pr Starts in the same way it was prior to the power down;

auto Starts in auto mode;

oP.0

Starts in manual mode with power output = 0;

St.bY Starts in stand-by mode.

aS.Pr

129 oPr.e Operative modes enabling

aLL

all modes will be selectable by the next parameter;

au.oP auto and manual (oPLo) mode only will be selectable by

the next parameter;

au.Sb auto and Stand-by modes only will be selectable by the next

parameter

aLL

130 oPer Operative mode selection

If oPr.e = aLL: - auto = auto mode;

- oPLo = Manual mode;

- St.bY = Stand by mode;

If oPr.e = au.oP:

- auto = auto mode;

- oPLo = Manual mode;

If oPr.e = au.Sb:

- auto = auto mode;

- St.bY = Stand by mode.

auto

]

Ser Group - Serial link parameter

no. Par.

description

dec.

Values

default Notes

131 add Instrument address

off;

1... 254.

1

132 baud baud rate

1200 1200 baud;

2400 2400 baud;

9600 9600 baud;

19.2

19200 baud;

38.4

38400 baud.

9600

133 trSP Selection of the value to be

retransmitted (Master)

none retransmission not used (the instrument is a slave);

rSP

The instrument becomes a Master and retransmits the

operative set point;

Perc The instrument become a Master and it retransmits the

power output.

none

]

COn Group - Consumption parameters

no. Par.

description

dec.

Values

default Notes

134 co.tY count type

off Not used;

1

Instantaneous power (kW);

2

Power consumption (kW/h);

3

energy used during program execution. This measure starts

from zero when a program runs end stops at the end of the

program. a new program execution will reset the value;

4

Total worked days: number of hours the instrument is turned

ON divided by 24;

5 Total worked hours: number of hours that the instrument is

turned ON;

6 Total worked days with threshold: number of hours the instru-

ment is turned ON divided by 24, the controller is forced in stand-

by when co.ty value reaches the threshold set in [137] h.Job;

7

Total worked hours with threshold: number of hours that the

instrument is turned ON, the controller is forced in stand-by

when co.ty value reaches the threshold set in [137] h.Job;

8

Totalizer of control relay worked days: number of hours the

control relay has been in ON condition, divided by 24;

9

Totalizer of control relay worked hours: number of hours the

control relay has been in ON condition;

10

Totalizer of control relay worked days with threshold: number

of hours the control relay has been in ON condition divided

by 24, the controller is forced in stand-by when co.ty value

reaches the threshold set in [137] h.Job;

11

Totalizer of control relay worked hours with threshold:

number of hours the control relay has been in ON condition,

the controller is forced in stand-by when co.ty value reaches

the threshold set in [137] h.Job.

off

135 uoLt Nominal Voltage of the load

1... 9999 (V)

230

136 cur

Nominal current of the load

1... 999 (a)

10

137 h.Job Threshold of the working

period

off Threshold not used;

0... 9999 days (when [134] cotY = 4);

0... 9999 hours (when [134] cotY = 5).

0

138 t.Job Worked time (not resettable)

0... 9999 days

]

CAL Group - User calibration group

no. Par.

description

dec.

Values

default Notes

139 aL.P adjust Low Point

from -1999 to (aH.P - 10) in engineering units

0

140 aL.o adjust Low Offset

-300... +300 (e.u.)

0

141 aH.P adjust High Point

from (aL.P + 10) to 9999 engineering units

9999

142 aH.o adjust High Offset

-300... +300

0

Note: To access all the instrument features, please see the “complete configuration procedure” in the “engineering user

Manual”.

complete configuration and Parameter setting can be easily uploaded from the controller and downloaded to

other controllers using the: configuration Key eLcO: KeY a-01.