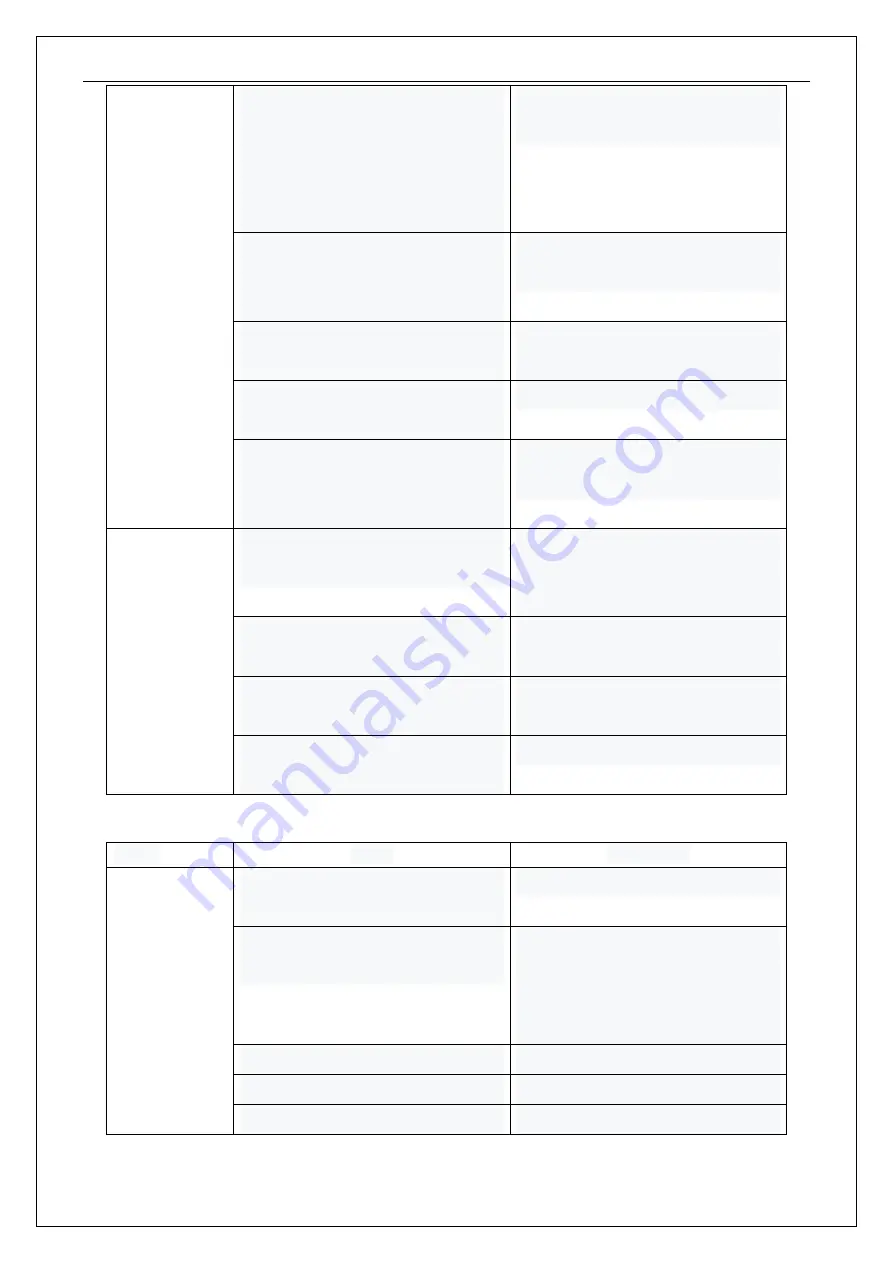

14

Oil

pump

noise

1. Most cases are caused by

insufficient oil absorption of oil pump,

such as blockage of oil absorption

filter; Oil level is too low; Inhalation of

air; Suction air at oil seal, etc

Keep oil level high and seal must be

reliable to prevent oil contamination

2. The return pipe is higher than the

oil level, and there are a lot of bubbles

in the oil

Immerse the return pipe below the oil

level

3. The viscosity of oil is too high and

the oil temperature is too low

Choose oil with proper viscosity

according to the season, or heat it up

4. The coaxial of the pump shaft and

prime mover shaft is too large

Adjust the coaxiality of the two axes

5. After maintenance, the driven gear

is inverted, and the meshing area

becomes smaller

Disassemble the oil pump and turn the

driven gear

Oil pump

temperature

rises too high

1, the pressure is too high, the speed is

too fast, the side plate burns

Properly adjust the overflow valve;

Reduce the speed to the specified

value; Repair the pump

2. The oil viscosity is too high or the

internal leakage is serious

Change the appropriate oil and check

the seal

3. The back pressure of oil return is

too high

Eliminate the cause of high return

back pressure

4, the fuel tank is too small, poor heat

dissipation

Increase the fuel tank

2.1.8 Other common faults and troubleshooting methods

Failure

cause

maintenance

Abnormal

sound during

exercise

1, hydraulic oil, gear oil and other oil

does not meet the requirements

Fuel until required

2, front and rear hub bearings loose,

broken

After tightening the bearing and

locking the nut, retract about 1/8 turn,

and the hub should be free to turn.

Fracture will renew the bearing

3, gearbox, gear, friction plate damage

replace

4, differential and cross shaft damage

replace

5. Fasteners are loose

Pry tight