Mechanical Operation and Maintenance Manual for ER20-1700 Industrial Robot

33

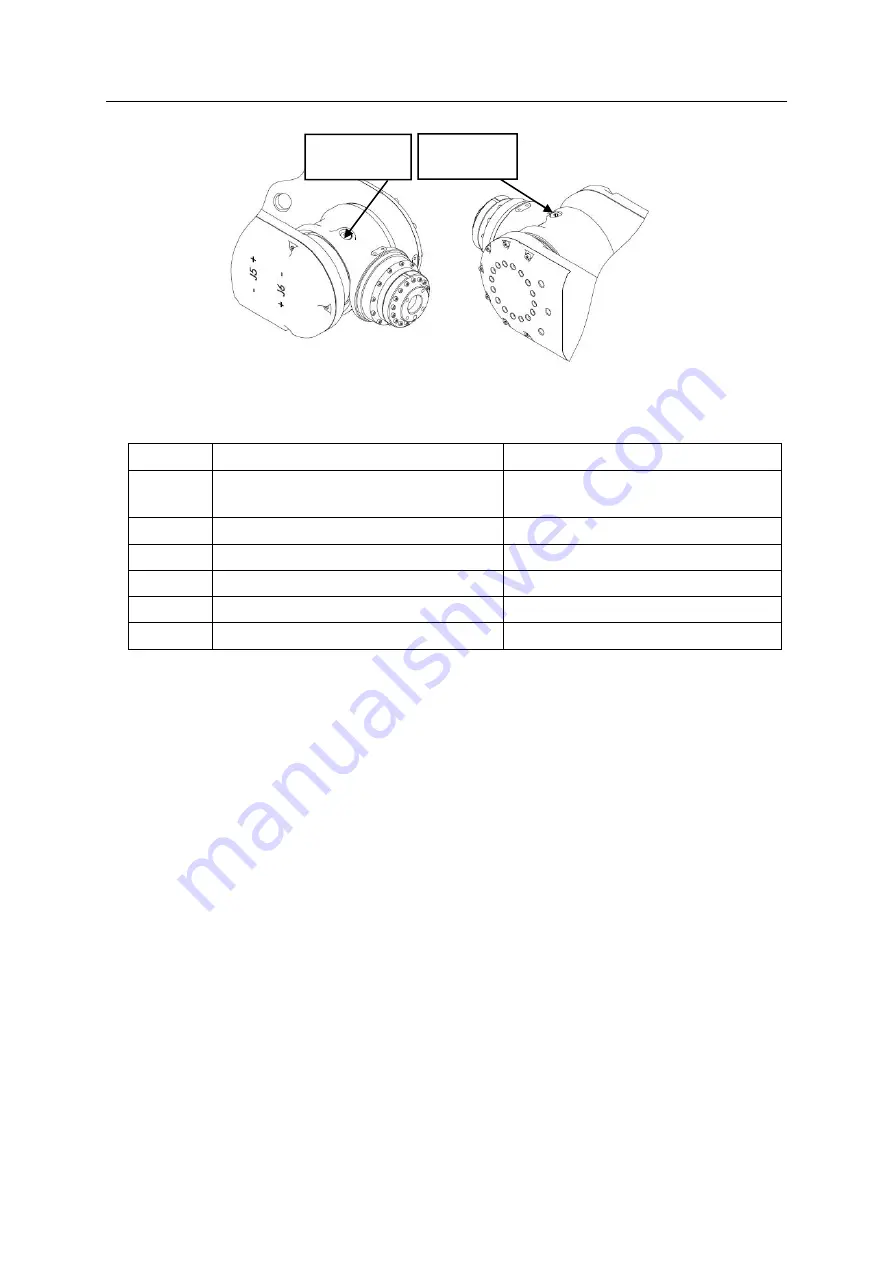

J5

注油口

Fig. 4-1 Inlet Port and Outlet Port Distribution

Table 4-3 Tools Required for Changing Lubricant

Number

格

Specification

Remarks

1

lubricant injector

with the function of measuring the

amount of lubricant

2

joint [M10x1]

1

3

hose [φ8x1m]

1

4

weight meter

weigh the lubricant

5

sealing tape

/

6

air source

/

4.3.4 Release Residue Pressure in Cavity

Operate the robot properly to release the residue pressure in the cavity after injection. Install a

recyclable bag under the inlet and outlet port to avoid lubricant splashing.

To release the pressure, keep the outlet port open, J1 axis within the range of

±

30

°

, J2/J3

axis within the range of

±

5

°

, J4 axis and J6 axis within the range of

±

30

°

, move for more than

twenty minutes in low speed state.

If the above movement cannot be performed due to surrounding situations, the robot should be

operated for the same number of times (When the axis angle can reach half, operation time should

be twice the original time). After the above movement is completed, install sealing screw plug with

combination pad or sealing tape on the outlet port.

4.4 Timing Belt Maintenance

Because the J5 and J6 axes are both driven by timing belt, operation for a period of time may cause

loosening and decline of performance precision. The timing belt may also be worn and cracked. If it is not

replaced and maintained, transmission failure and economic loss may occur. Therefore, it is recommended

to check the running state of the timing belt regularly (every half year). The loosening part should be

tightened and the damaged should be replaced to ensure the transmission precision and stability of the

timing belt.

J5 inlet port

J5 outlet port