EFORT Intelligent Equipment Co., Ltd

32

1

)

Open the outlet and remove the plug or screw before lubrication.

2

)

Use an injector which can specify the amount of lubricant to slowly and gently inject lubricant under

the speed of 40cc/10 seconds. Otherwise, measure the weight of lubricant before and after the

injection to confirm the injected amount.

3

)

Grease the valve on the injection side and be careful not to let air in.

4

)

If the required amount is not reached, a precision regulator for air supply can be used to squeeze the air

in the cavity before reinjection. The air pressure should be controlled under 0.025MPa.

5

)

Only use specified lubricant. Otherwise, damage of the reducer or other problems may occur.

6

)

When installing hexagon head plug after the injection, coil sealing tape to avoid leak at the outlet port.

7

)

To avoid accidental slip and fall, excess lubricant on the ground and the robot should be completely

removed.

8

)

Follow the steps in 4.3.4 to release the residual pressure in the lubricant tank and install hexagon head

plug. Coil sealing tape to avoid lubricant leak at inlet and outlet ports.

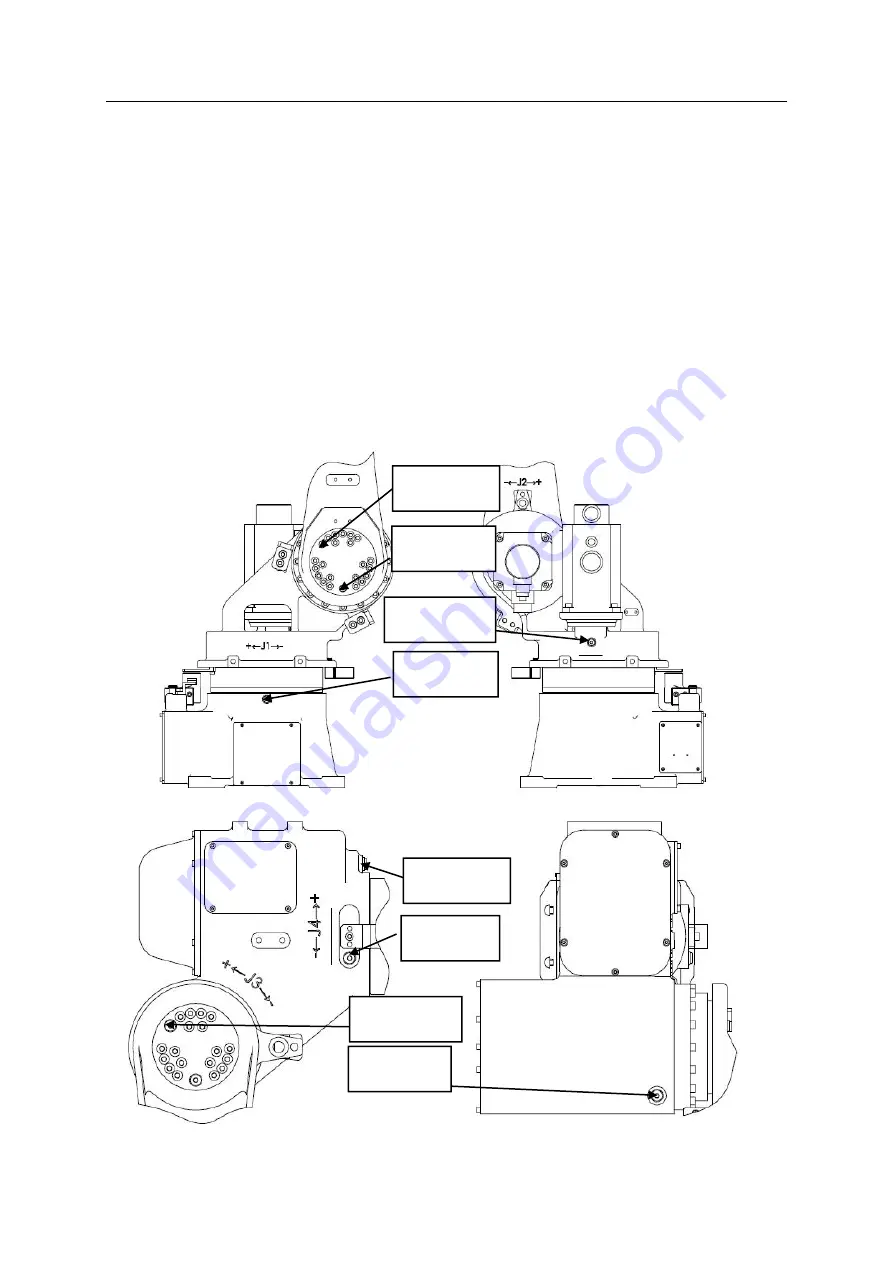

J

J

J

J

J

J2 outlet port

J2 inlet port

J1 outlet port

J1 inlet port

J4 outlet port

J4 inlet port

J3 outlet port

J3 inlet port