12

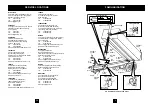

A body prop is considered by Edbro to be an Essential Safety

Requirement. A prop must always be used if maintenance needs to be

undertaken with the body raised.

•

never attempt to prop a loaded body

•

use a prop designed to locate securely between the body

underframe and chassis

•

the prop must be between body and chassis, not between the

body and the ground

•

lower the body gently onto the prop to minimise damage

•

confirm that the prop is sufficiently strong to carry the

bodyweight.

IT IS THE OPERATOR'S RESPONSIBILITY TO ENSURE THAT

ONLY FULLY TRAINED PERSONNEL REPAIR OR SERVICE

THIS EQUIPMENT. IF NECESSARY, CONTACT YOUR LOCAL

SERVICE AGENT FOR ASSISTANCE.

SAFETY DURING MAINTENANCE

Typical body-prop arrangement

13

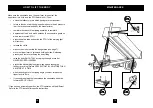

MONTHLY

Make sure the body is down, the handbrake is on and the engine is

switched off. Then top up the oil in the tank to dipstick level with clean

hydraulic oil (refer page 16).

Use a grease gun to lubricate the points shown in the inset diagrams on

pages 14 or 15 with a good quality, multi-purpose grease.

Grease the taildoor hinge and locking mechanism.

Replace any worn or damaged flexible pipes.

Make sure all flexible pipes are secured to the chassis and are not

hanging loose.

Check the outer cover fixing studs are tight.

Tighten any loose pipe connections.

Check and tell your Edbro service dealer if:

•

the outer cover (where applicable) is loose (side-to-side or

rotating)

•

any ram tube is damaged

•

the base ram nut is loose

•

the ram trunnion arms, the outer cover trunnion arms, or the rear

hinge brackets are worn

•

oil is leaking from the ram tubes, tipper valve, PTO, pump or

flexible pipes

•

air is leaking from the air pipes

•

air is leaking continuously from the controls

THREE MONTHLY

Use spanners to check the tightness of the fixing bolts on the tipper

valve, PTO and brackets.

YEARLY (more often in dusty or dirty conditions)

Drain and refill the tank with clean hydraulic oil (refer page 16). In order

to protect the environment, ensure that no oil is spilled when draining,

and old oil is disposed of correctly.

Depending on the specification of your equipment, other maintenance

checks may be required. These should be advised by the bodybuilder/

installer.

MAINTENANCE