8

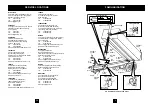

CONTROLS

17

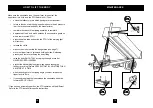

BLEEDING THE SYSTEM

•

loosen the hose connection at the cylinder

•

then with the pump running at low speed, put the control valve

into 'TIP'. After a few seconds any air will have escaped and the

connections can be tightened.

Warning: Take care to guard against the escape of high

pressure oil

•

tip the hoist to full stroke and leave the pump running on engine

tick-over with the control in 'TIP' for approx. 5 minutes. This will

purge the cylinder of air through the oil into the tank and

filler/breather

•

if the hoist still shows signs of trapped air, tip the body to full

stroke a further 10 times, and at the end of each stroke leave the

cab control in 'TIP' for about 30 seconds before lowering

•

finally, re-check the oil level

For later cylinders with a bleed screw (approxiamately, serial numbers

after LH017000 / LM002100).

•

lift the body to about 300mm (12") above the chassis frame

•

put the tipper lever in 'HOLD'

•

locate the bleed screw and slacken about one turn

•

the body will come down slowly and force the air out of the

system

•

when oil flows freely, tighten the bleed screw

•

if the hoist is still jerky, or sluggish, repeat the whole procedure

•

lower the body, and top up the tank with clean oil

•

replace the plastic cap on top of the outer cover

Bleeding an outer cover hoist

Bleeding an eye-ended hoist

Your Edbro hoist works best if the vehicle is fitted with matching Edbro

hydraulics (PTO, pump, valves, oil tank, pipes and controls).

The PTO and tipper controls are combined in one unit and work off the

vehicle's air system (fig. a).

The PTO control switch is fitted with a PTO engaged warning light.

The tipper control is a lever with four safety features:

•

a spring-loaded device stops it from being accidentally moved

into 'raise' or 'lower'

•

a spring return to 'hold' from 'raise' position, known as a

deadman's handle function, ensures the driver keeps his hand

on the tipper control all the time the body is being raised

•

when the lever is moved from 'hold' towards 'lower', the PTO is

automatically disengaged; this internal mechanical feature

prevents PTO, pump or gearbox damage if you forget to

disengage the PTO before driving off

•

controlled lowering (feathering) regulates speed of descent for

loaded or part-loaded bodies.

This type of control is recommended for conformity with European

standards. Other controls are available but, if used, the bodybuilder will

need to ensure that all Essential Safety Requirements are covered by

other means. For example, separate controls are available (fig. b).

*Alternative combined controls without automatic PTO disengagement

feature (for spreading or static discharge applications) are available.