8 - COMBUSTION AIR AND VENT PIPE

8.1 Connections And Termination

Boilers for connection to gas vents or chimneys, vent

installations shall be in accordance with “Venting of

Equipment” of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, or “Venting Systems and Air Supply for

Appliances”, of the Natural Gas and Propane Installation

Code, CAN/CSA B149.1, or applicable provisions of local

building codes.

Provisions for combustion and ventilation air must be

in accordance with section, Air For Combustion and

Ventilation, of the National Fuel Gas Code, ANSI 2223.1/

NFPA54, National Gas and Propane Installation Code, CAN/

CGA-B 149.1, in absence of such requirements to the

Authority having jurisdiction.

Boilers require dedicated direct vent system. All air for

combustion is taken directly from outdoors through

combustion air intake pipe. All flue products are discharged

to outdoors through vent pipe.

1.

See

Figures 5 and 6 for two pipe combustion air

and vent pipe roof and sidewall termination. Roof

termination is preferred. Combustion air and vent pipes

must terminate together in same atmospheric pressure

zone as shown.

2.

Use of concentric vent termination see Figures 7-9for

proper setup.

3.

For Canadian installations all plastic venting material

must be listed to ULC S636.

4.

Construction through which vent and air intake pipes

may be installed is maximum 24 inches, minimum ¼”

thickness.

5.

See Table 5 for combustion air and vent pipe fittings

approved material and standards.

6.

Canada

construct all combustion air and vent pipes

for this unit of ULC S636 listed schedule-40 CPVC,

schedule-40 PVC, PVC-DWV or ABS-DWV pipe and pipe

cement. SDR pipe is not approved in Canada.

• First 3 feet (900mm) of venting must be readily

available for visual inspection.

• Specified primers and glues of certified vent

system must be from single manufacturer, and not

intermixed with other manufacturer’s vent system

parts.

• Components of the certified system must not be

interchanged with other vent systems, or unlisted pipe

and/or fittings.

NOTICE

Transition from 2” pipe to 3” pipe must be made in

vertical run.

7.

Boiler combustion air and vent pipe connections are 2”

but must increase to 3”. Due to potential for flue gas

temperatures above 155°F, first 30” of supplied vent

pipe is CPVC while remaining vent pipe can be PVC. Any

replacement of first 30” of vent pipe must be made with

CPVC.

8.

Covering non-metallic vent pipe and fittings with thermal

insulation shall be prohibited.

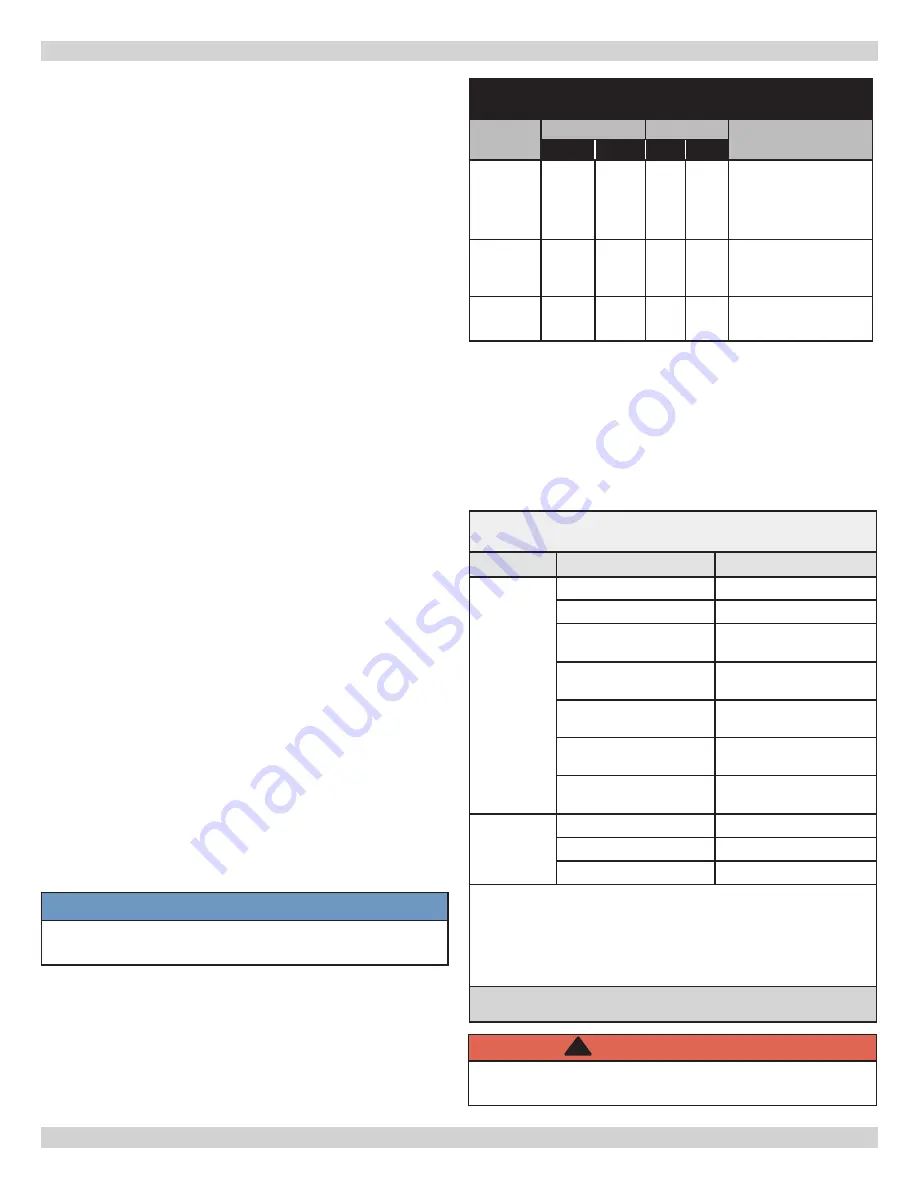

TABLE 4

Maximum Allowable Temperatures

Of Typical Non-Metallic Vent Material

Material

HDT

RTI

Standard

°F

°C

°F

°C

PVC

158

70

–

–

ASTM F 891 *

ASTM D2665 **

ASTM D1785 **

ASTM D2241 **

CPVC

210

100

–

–

ASTM D2846 **

ASTM F441 **

ASTM F442 **

ABS

180

82

–

–

ASTM D2661 ***

ASTM F628 ***

*

Allowable temperatures based on Classifications covered in ASTM

D4396 [Deflection Temperatures under Load (264psi) (1819 KPa)].

** Allowable temperatures based on Classifications covered in ASTM

D1784 [Deflection Temperatures under Load (264psi) (1819 KPa)].

*** Allowable temperatures based on Classifications covered in ASTM

D3965 [Deflection Temperatures under Load (264psi) (1819 KPa)].

Length of pipe is counted from end of supplied 2” CPVC

pipe exiting boiler. Termination is not counted in “Total

Equipment Length.”

Table 5 - Combustion air and vent pipe fittings

must conform with the following:

Item

Material

Standards

Vent Pipe

and Fittings

PVC schedule 40

ANSI/ASTM D1785

PVC - DWV

ANSI/ASTM D2665

CPVC schedule 40

ANSI/ASTM D1784/

F441

SDR-21 & SDR-26 PVC

ANSI/ASTM D2241

ABS-DWV

ANSI/ASTM D2661

Schedule 40ABS

ANSI/ASTM F628

PP (Polypropylene)

Pipe and Components

UL 1738

ULC S636-08

Pipe

Cement/

Primer

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

Schedule 40 ABS

ANSI/ASTM D2235

• IPEX is approved vent manufacturer in Canada listed

to ULC-S636.

• IPEX System 636 Cements and Primers are approved

in Canada listed to ULC-S636.

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel

®

,

(Polyphenolsulfone) in venting systems shall be prohibited.

WARNING

Use of cellular core PVC for venting flue gas could

result in death, or serious injury.

!

12

Summary of Contents for Dunkirk Q95M-200

Page 2: ...1 DIMENSIONS OPENING FOR SAFETY RELIEF VALVE DISCHARGE PIPE 30 785mm 39 1 1m 18 458mm 2 ...

Page 27: ...APPENDIX A BOILER PIPING AND WIRING Electrical Wiring Diagram 27 ...

Page 49: ...49 NOTES ...

Page 50: ...50 NOTES ...

Page 51: ...51 Company Address Phone Company Name Tech Initials Service Performed Date SERVICE RECORD ...