6.1 Locating the Boiler

1.

Place crated boiler as close to selected location as

possible and un-crate boiler. Boiler may be moved into

position with appliance dolly or 2 wheel hand truck.

Insert dolly or hand truck under

right hand side

of

boiler. It is possible to slide boiler for short distance on

smooth floor or surface.

2.

Select level location central to piping systems served

and as close to vent and air intake terminals as

possible.

3.

Accessibility clearances, if more stringent (i.e. larger

clearances) than required fire protection clearances,

must be used for boiler installation. Accessibility

clearances may be achieved with use of removable

walls or partitions.

WARNING

Fire hazard. Do not install on carpeting. Failure to

follow these instructions could result in death or

serious injury.

!

4.

Boiler is approved for installation in closets and on

combustible floors. Boiler shall NOT be installed on

carpeting.

5.

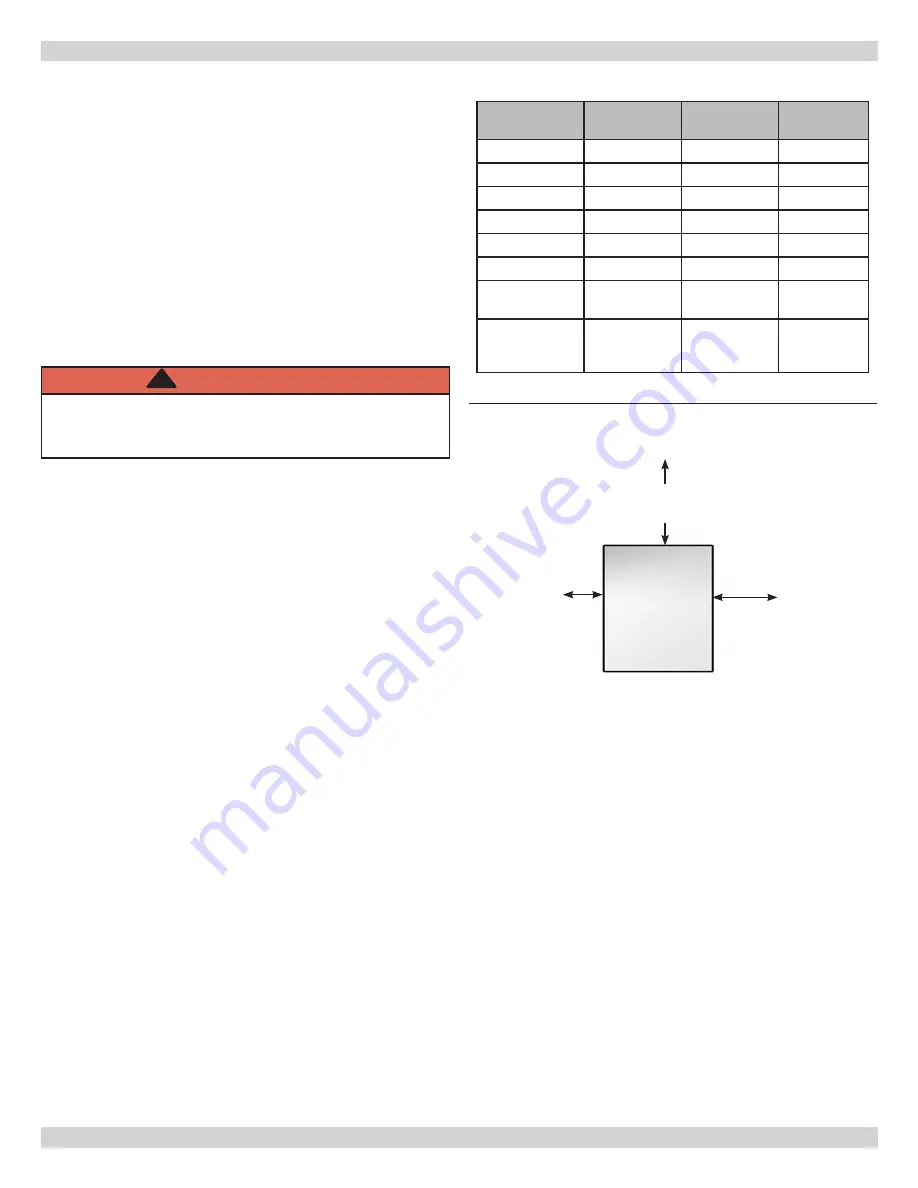

Clearances shown in Table 3 indicate required

clearances per CSA listing. Minimum 1” (26mm)

clearance must be maintained between combustible

construction and each of the right, top and back

surfaces of the boiler. Allow at least 24” (610mm) at

front and left side and 8” (204mm) at top for servicing.

No combustible clearances are required to venting or

combustion air intake piping.

6.

Install equipment in location which facilitates operation

of venting and combustion air intake piping systems as

described in this manual.

7.

Advise owner to keep venting and combustion air

intake passages free of obstructions. Both venting

and combustion air intake piping systems connected

to outdoors must permit flow through piping systems

without restrictions for boiler to operate.

8.

Install boiler so automatic gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during operation and service

(circulator replacement, control replacement, etc.).

9.

Keep boiler area clean of debris and free of flammable

and combustible materials, vapors and liquids.

10.

Locate boiler where ambient room temperatures

(minimum possible temperatures where boiler is

installed assuming boiler is not in operation and

therefore contributes no heat to space) are always

at or above 32°F (0°C) to prevent freezing of liquid

condensate.

Figure 1 - Minimum Clearances To Combustible

Construction

8”

Boiler

Rear

Front

Right Side

Left

Side

1”

(26mm)

1”

(26mm)

6”

(153mm)

0”

(0mm)

TABLE 3: BOILER CLEARANCES

Dimension

Combustible

Construction

Accessibility/

Cleaning

Service

Top

1” (26mm)

8” (204mm)

8” (204mm)

Left Side

1” (26mm)

24” (610mm) 24” (610mm)

Right Side

1” (26mm)

-

-

Base

Combustible

-

-

Front

0

24” (610mm) 24” (610mm)

Back

6” (153mm)

-

-

Intake/Vent

Piping

0

-

-

Near Boiler

Hot Water

Piping

1” (26mm)

-

-

6 - LOCATING THE BOILER

7

Summary of Contents for Dunkirk Q95M-200

Page 2: ...1 DIMENSIONS OPENING FOR SAFETY RELIEF VALVE DISCHARGE PIPE 30 785mm 39 1 1m 18 458mm 2 ...

Page 27: ...APPENDIX A BOILER PIPING AND WIRING Electrical Wiring Diagram 27 ...

Page 49: ...49 NOTES ...

Page 50: ...50 NOTES ...

Page 51: ...51 Company Address Phone Company Name Tech Initials Service Performed Date SERVICE RECORD ...