21

ECOWATER

S Y S T E M S

Non-Wi-Fi Systems Only: Remote Operation

CHANGING THE ORDER OF DATA ITEMS

DISPLAYED IN THE STATUS SCREENS

In addition to changing which data items the remote dis-

plays during normal operation, the order of these items

may be customized, as follows:

1

. Press the remote’s LEFT (

3

) or RIGHT (

4

) buttons

to manually advance to the status screen you want to

customize. For example, to change the order of the

conditioner/refiner’s screen, manually advance to the

EWS 3500

status screen.

2

. Press the remote’s SELECT (

¡

) button to display the

device menu.

3

. Press the DOWN (

6

) button to scroll through the

menu options until

Display order

is highlighted in a

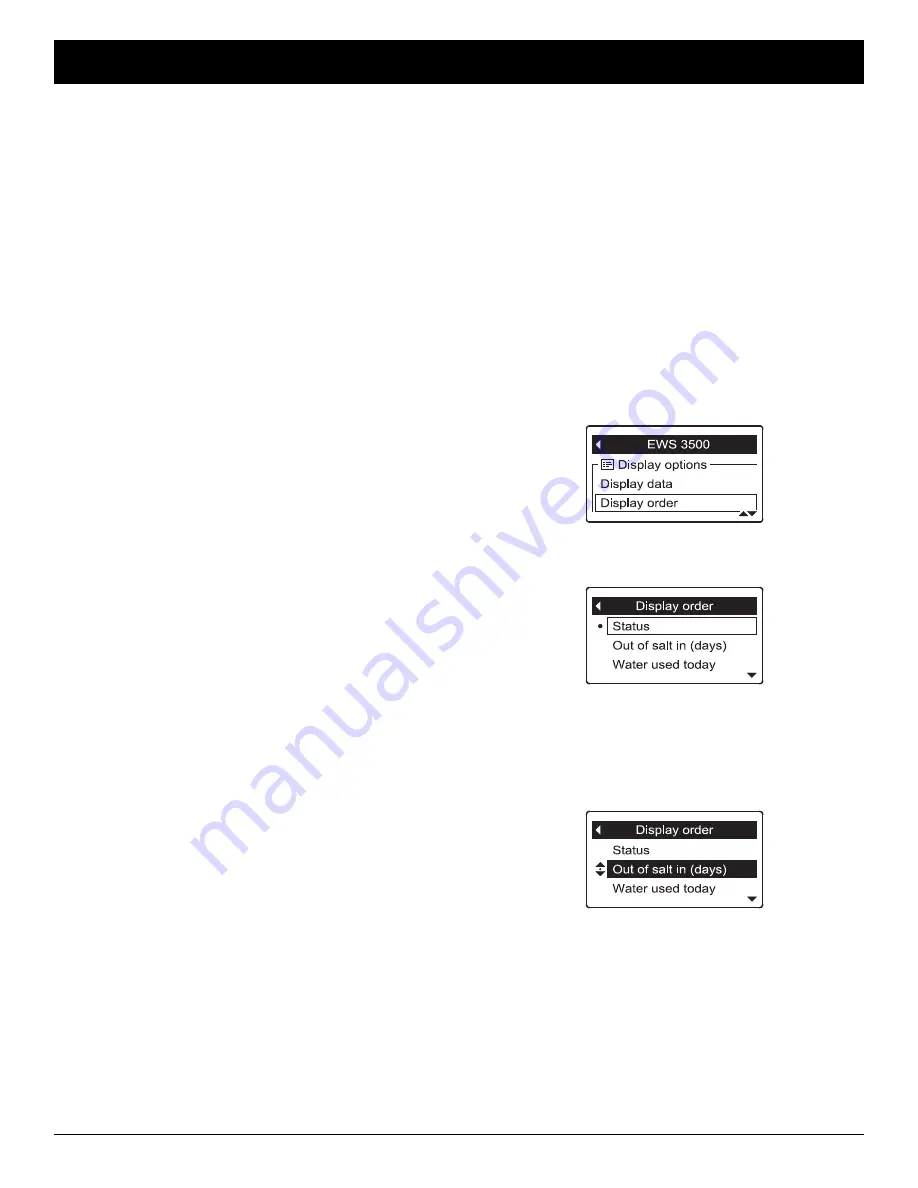

box (See Figure 66).

FIG. 66

4

. Press the SELECT (

¡

) button to display the Display

order screen (See Figure 67).

FIG. 67

FIG. 68

5

. Press the DOWN (

6

) or UP (

5

) buttons to scroll

through the list of display data items. Stop when the

item you want to move is highlighted in a box.

6

. Press the SELECT (

¡

) button. Arrows will appear

next to the item (See Figure 68).

7

. Press the UP (

5

) or DOWN buttons to move the

item higher or lower in the list.

8

. When the item is where you want it in the list, press

the SELECT (

¡

) button. The arrows next to the item

will disappear.

9

. To move another item, return to Step 5. When fin-

ished moving items, press the LEFT (

3

) button. The

display will go back to the device menu (Figure 66).

5

. Press the DOWN (

6

) or UP (

5

) buttons to scroll

through the list of display data items. Items with a

check mark in the box next to them will be displayed

during normal operation.

6

. To select an unchecked display data item, make sure

the box next to the item’s name is highlighted (box is

black inside). Then press the SELECT (

¡

) button.

The check mark will appear in the box.

7

. To un-select a checked display data item, make sure

the box next to the item’s name is highlighted (box is

black inside). Then press the SELECT (

¡

) button.

The check mark will disappear.

8

. When selections are complete, exit this menu by

pressing the LEFT (

3

) button. The display will go

back to the device menu (Figure 64).

9

. Press the LEFT (

3

) button to exit this menu, or wait

30 seconds for it to exit automatically.

OUT OF SALT IN (X) DAYS

This display, on both the conditioner/refiner and remote

status screens, is an

estimate

of the number of days

until the conditioner/refiner will be out of salt. This esti-

mate is based on salt level in the brine tank, salt dose

used, and average daily water use. It is recalculated

when the conditioner/refiner regenerates, and the num-

ber of days may decrease, remain the same or even

increase at regeneration time (a drop in water use could

cause the estimated days left to increase). Between

regenerations it will count down.

PHOTO CELL

To prolong battery life, the remote has a photo cell

above the display (See Figure 42). This cell triggers

the display to “go to sleep” (turn off) when the ambient

light level stays low for 10 minutes. The display will

immediately turn back on when the ambient light level is

increased.

NOTE:

The “Alert” LED (See Figure 42) will not “go to

sleep” if ambient light levels are low.