13

®

Rotor

L

N

C

1.

Manžeta

Cleaning & maintenance

The food waste disposer a maintenance-free device and usually requires no further attention.

The grinding chamber and grinding segments of the waste disposer are cleaned by the grinding process at each use. Fragments of crushed

materials, especially egg and nut shells, act lightly abrasive and do not allow for larger food waste deposits.

If, however, you decide to clean the device, pour some ice cubes into the grinding chamber, add a cup of salt, cover the drain with a stopper

(do not run the water yet), turn on the disposer and let it run until the crushing sound of ice is no longer heard, then remove the stopper, run the cold

water for a while and then turn off the disposer. This cleaning method removes deposits and bits of food waste from the grinding chamber.

You can also rinse the disposer with acetic water or baking soda. To freshen the disposer, use orange or lemon peel for a pleasant smell.

Fora professional solution, use

Disposer Care cleaning capsules or powder

, see chapter

„Waste disposer accessories“

.

Use as needed to keep your waste disposer and siphon trap smelling clean and fresh.

Mineral and lime deposits can also build up on the turntable and grinding segments of the disposer. These deposits may look like rust,

but don‘t worry, all crushing components are made of stainless steel.

The motor of the waste disposer has sliding, self-lubricating bearings. LUBRICATION IS NOT REQUIRED. There is no need to sharpen the grinding

segments. Due to the vibrations caused by grinding it is recommended to perform intermittent CHECKS of the tightness of the disposer mount as-

sembly and all other connections and nuts on the siphon trap waste pipe. Over time they may get loose and cause possible leaks.

It is advisable to occasionally remove and clean with a brush the underside of the rubber splash guard

impurities (Fig. 1), where food particles deposit and may decompose over time.

You can also put the splash guard in the dishwasher. After some time or in case of damage, replace the

splash guard for a new one, see the chapter

„Waste disposer accessories“.

Always return the plash guard to the sink flange by pushing it down until it sets on the rim,

which is approx. 5 cm under top edge of the flange. If the splash guard is not set properly,

it may be misaligned and may fall into the grinding chamber.

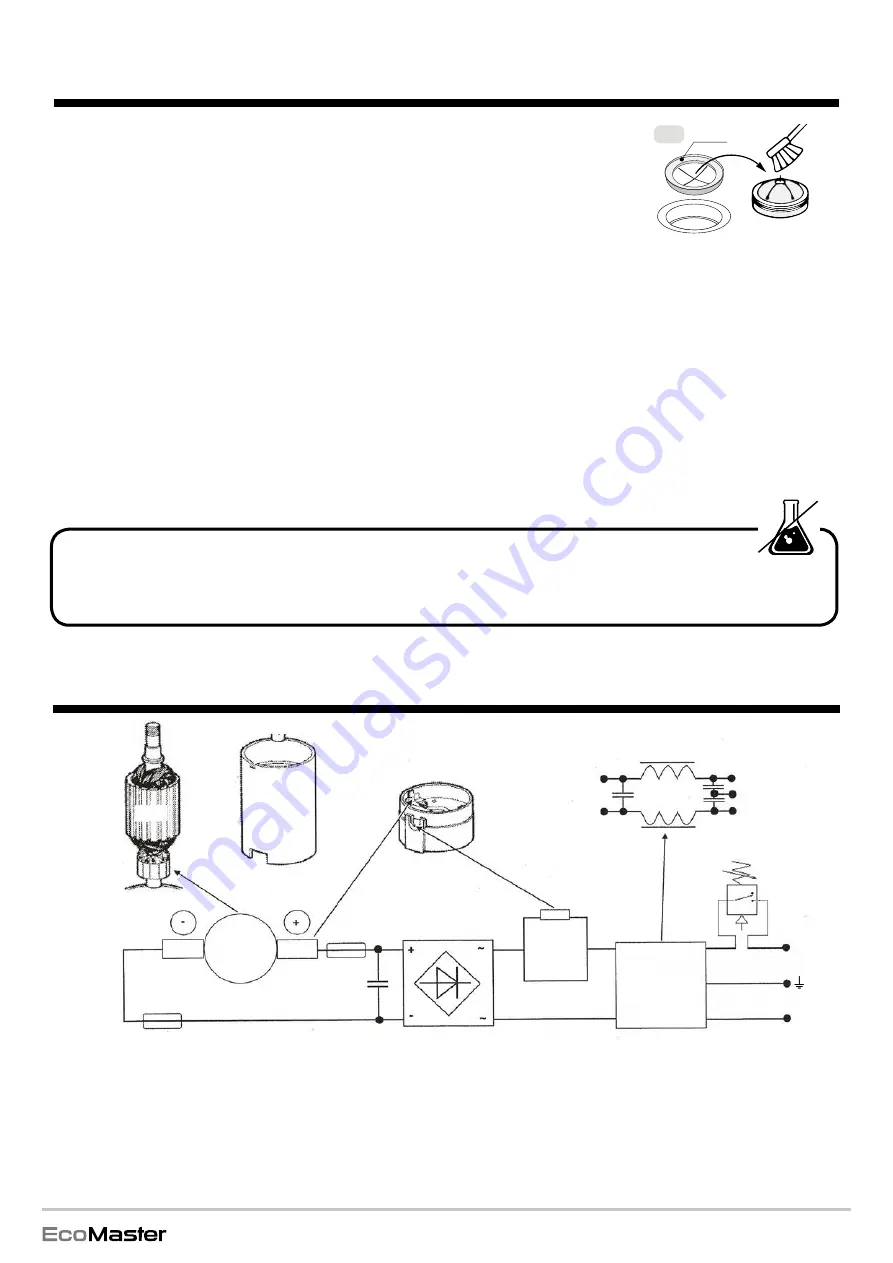

Wiring diagram

Never pour aggressive substances into waste disposer!

For example: bleach, chemical waste cleaner, etc. Chemicals may weaken the gasket seals and cause subsequent leakage

into the disposer damaging the motor by shorting electrical parts.

If you need to dissolve food deposits in the waste pipes and want to use one of the suited chemical preparations,

you MUST pour them directly into the waste pipe, NEVER into the disposer.

NOTICE

Stator

with permanent

magnets

Lower part of the motor

RFI filter

Carbon

Carbon

Commutator

Ferrite

Ferrite

RFI filter

Protective

fuse

overload

Diode bridge

(rectifier)

Pressure switch

Overload protection has two triggers connected in series:

1) Short-circuit (non-reversible)

– it consists of a hot wire. Typically, the wire is burned (interrupted) in the event of a short circuit in the rotor winding,

commutator in the event of a diode bridge failure, thereby protecting the supply line.

2) Thermal (reversible)

– consists of a bimetallic strip with contact and tripping mechanism. (Bimetallic - mechanically bonded two metal strips

of different thermal expansion) The bimetallic strip is heated by too much current passing through it, deformed in a given direction and activates the

tripping mechanism, which breaks the circuit. After relieving the overloaded motor and cooling the bimetal strip, the protection can be switched on again.

This protection is not thermally bonded with the rotor, therefore, it cannot react to an increase in temperature, caused by excessive long use, even if the

motor is not overloaded.

Summary of Contents for DELUXE EVO3

Page 20: ......