ecom-EN3

Page 23

2

3

4.1.1

Adaptation of the displays for gas analysis

Hint

The position of the measured and calculated values (gas analysis sub-menu)

on the display pages is free selectable

For alteration of the existing succession, proceed as follows:

- Press <Enter> / „Display values“ / <Enter> to activate the function

- Select line with cursor keys (Up/Down)

- Select desired parameter with cursor keys (Right/Left)

- Repeat procedure until desired layout is completed

- Press <Enter> to deactivate the function

4.1.2

Positioning the probe, search the core stream

Hint

The correct positioning of the probe in the gas stream is necessary in order to

achieve an impressive measuring result.

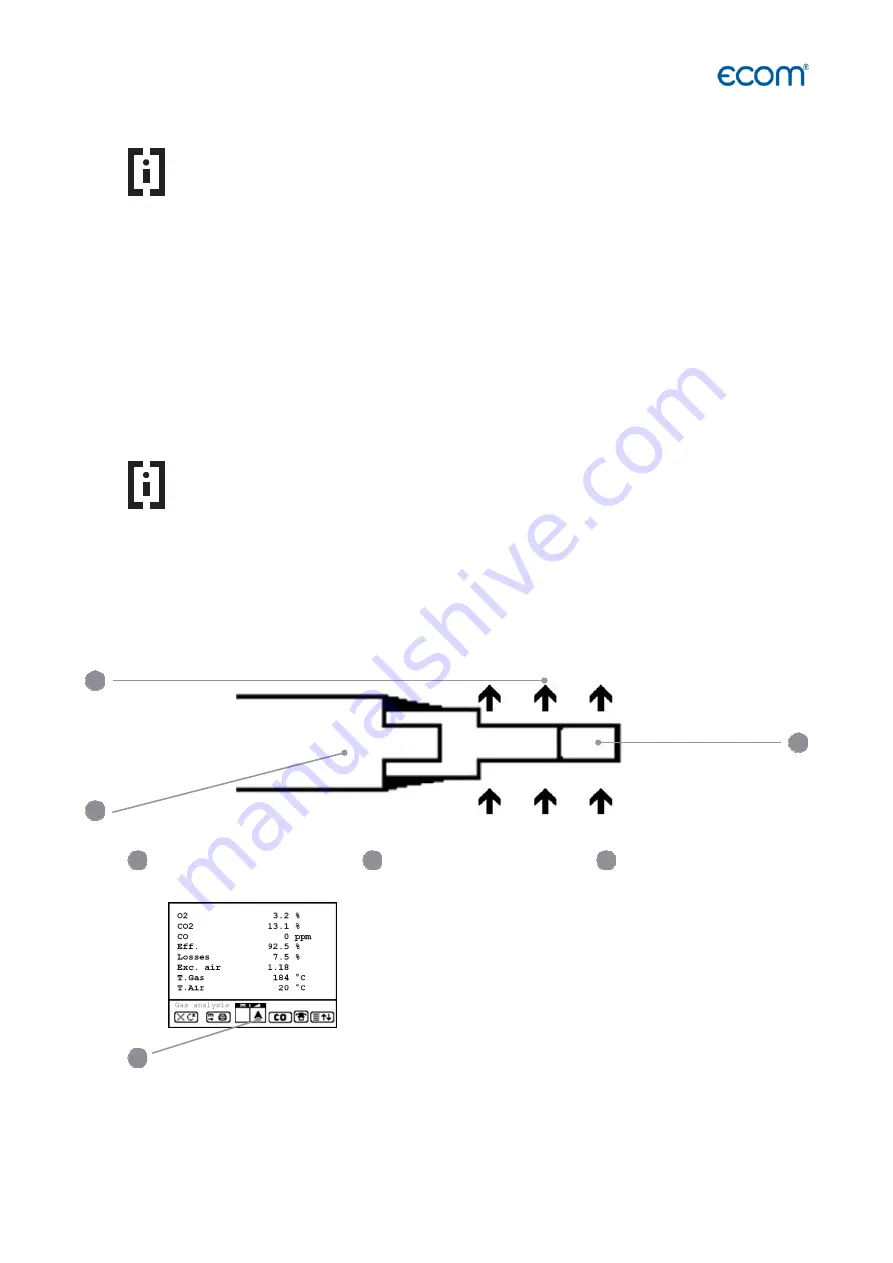

To correctly position the probe in the gas stream, proceed as follows:

- Connect the probe hose to the device "connection gas temperature"

- Position the sampling probe in the exhaust channel, so that the thermocouple is fully

surrounded with the gas (see drawing).

Gas stream

Protection bow

Probe tip

4

Core stream search

Position the sampling probe in the exhaust channel

(Position in the hottest gas temperature area).

Observe trend for T.Gas in the measurement display.

As long as the display shows an arrow in upwards

direction, the measured temperature increases, it means

the probe tip moves towards the core stream center.

If an arrow in downwards direction is displayed, it means you move the probe away from the

core stream and the temperature sinks.

1

2

1

3

Summary of Contents for EN3

Page 1: ...Operating Instructions The ecom EN3 meets the requirements of the DIN EN 50379 Part 2 ...

Page 5: ...ecom EN3 Page 5 ...

Page 26: ......

Page 64: ......