7.0 SYSTeM OperaTING feaTUreS

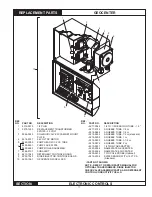

DETERGENT CONTROLLER P.C. BOARD

FeeD LIGHT

100% LIGHT

Figure 7-1

7.1 power Lights

The “POwER” light on the front of the unit is lit when the

unit is powered. If this light flashes, the power is below the

minimum 19 volts required for proper operation of the unit. If

this occurs, it may be necessary to locate an alternate power

source. The power light for the rinse injector is illuminated

whenever the rinse injector is operating.

7.2 feed Light

This light will be illuminated whenever the wash tank con-

centration is BELOw the control set point.

7.3 100% Light

This light will illuminate whenever the wash tank concentration

is at, or above, the control set point,

refer to Figure 7-1.

NOTE: This light will flash at the appropriate time the

wash solution should be titrated. This will verify the

desired control set point

.

7.4 Temperature compensation

The

concentration

of the dissolved detergent in the wash

tank remains the same at any water temperature. However,

the

conductivity

signal produced by a given concentration

varies noticeably with water temperature. In general, the

higher the wash tank temperature, the higher the conductiv-

ity signal. This can cause the detergent controller to feed

less detergent product when the wash tank temperature

increases and more when it decreases.

The S-2000 Sensor incorporates a thermistor that measures

the wash tank temperature. The detergent controller PC

board uses this temperature measurement to automatically

adjust the detergent feed to maintain a desired concentration

over a wide range of wash tank temperature.

Due to limitations in sensor technology, the thermistor in the

S-2000 sensor responds slowly to changes in wash tank

temperature. under certain conditions this slow response

can cause the detergent controller to respond improperly to

changes in wash tank temperature and feed erratically.

If erratic detergent feed is occurring, the temperature

compensation feature of the S-2000 sensor can be re

-

moved by disconnecting the sensor brown wire from

terminal #15 on the detergent controller PC board.

NOTE - This will cause the desired detergent concentra-

tion to drop significantly, which will require resetting the

TITRATION DIP switch according to Section 6.2.

NOTE - When using a two-pole cell, temperature com

-

pensation is not functional, so detergent concentration

will vary with wash tank temperature. For this reason,

it is important to adjust titration using a two-pole cell

ONLY when the wash tank is at the correct operation

temperature.

7.5 Optional Jumper Settings

There are two additional jumper settings on the detergent

controller PC board that are not normally used in standard

installations. The function of these additional jumpers is

explained here when a specific application requires them.

JP1 - FEED OFF - Installing this jumper will stop deter

-

gent feed when the empty product alarm is active. To

start the unit feeding again the product container must

be refilled and power to the unit must be turned OFF

and back ON again.

JP2 - HI (left two pins of JP2) - Installing this jumper will

multiply the TITRATION DIP switch position settings by

a factor of 10 times. This allows the use of very high

detergent concentrations that exceed the maximum

setting of 63 drops. For example, turning ON position 3

and 4 with this jumper installed will result in a desired

titration of about 120 drops.