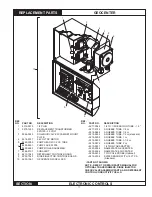

6" MIN (uS)

30 cm (INT'L)

w

AT

ER FLOw

Visual Flow

Indicator

1/8"

TuBE

1" x 1/4" OD

TuBE

TuBE CLAMP

INDICATOR TuBE

TuBE CLAMP

1" x 1/4" OD

TuBE

1/8"

TuBE

Figure 4-3

4.7 Geosystem rinse Dispenser

1. Install the Geosystem Rinse Dispenser following the

installation instructions provided for that unit.

4.8 rinse Injector connections

Identify the point at which rinse additive will be injected into

the final rinse line,

refer to Figure 4-3.

NOTE: The injection point has to be installed a minimum

of 6" (15.2 cm.) below the vacuum breaker with the cabinet

mounted at or below that point. In many International

accounts the minimum distance beneath the vacuum

breaker is 30 cm. (11.8"). Install fitting using Teflon tape

or pipe sealant to prevent leakage.

4.9 Hydraulic connections and Visual flow

Indicator

1. Connect 1/8" product discharge tubing between the outlet

of the pump squeeze tube and visual flow indicator,

refer

to Figure 4-3.

Note: The visual flow indicator is required for NSF

listing.

2.

Assemble the Visual Flow Indicator by inserting the 1/8"

tube fully into one of the two 1" sections of 1/4" OD x

1/8" ID PVC tubing provided.

3. Insert this injection tubing assembly fully into the outlet

end of the Flow Indicator tube, also called the sight

tube.

4. Secure all connections with the clamps provided.

5. Complete the outlet of the Visual Flow Indicator in the

same manner and extend the 1/8 tubing to the check

valve and injection fitting.

Refer to Figure 4-3.

IMPORTANT: When the product is being injected into

the final rinse line, movement of the product will be

visible in the flow indicator tube. The dishmachine

operator must be instructed to observe the Flow

Indicator periodically to insure that product is in

fact being dispensed.

6. Trim and connect the 1/8" product pick-up tubing supplied

with the rinse injector to the inlet side of the pump

.

7. Connect 1/4" O.D. copper tubing from the water source to

the inlet side of the solenoid valve located at the bottom

on the GeoCenter cabinet,

refer to Figure 4-4.

8. Connect 1/4" O.D. copper tubing from the outlet side of the

solenoid valve to the Geosystem Detergent Dispenser.

Refer to the Installation and Operation Manual

of the

Geosystem Detergent Dispenser used to determine

wATER IN

SOLENOID

VALVE

TO GEOSYSTEM

DETERGENT

DISPENSER

VACuuM

BReAKeR

INJECTION

FITTING

CHeCK

VALVE

PRESSuRE

SWITCH

TO

GEOSYSTEM

RINSE

DISPENSER

Figure 4-4