22

7058-206E

August 30, 2016

HEATILATOR ECO CHOICE

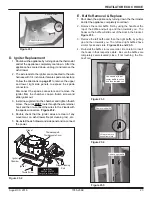

B. Exhaust Blower Replacement

1. Turn down the thermostat, let appliance completely cool

and then unplug appliance before servicing.

2. Remove both upper and lower right side curtains.

Figure

22.2. on page 22.

3. Disconnect 2 white wires from the white and blue wires of

the exhaust blower.

4. There is a removable plate on the exhaust blower.

Depending on the model, use a 1/4 inch socket, or 1/4

inch Nut Driver or #2 Phillips Head screw driver to loosen

the 6 screws in the keyhole shaped holes and rotate the

plate. It is only necessary to loosen screws.

Figure 22.1.

5. Remove the exhaust blower and gasket.

6. Check for degradation on the gasket and replace if nec-

essary using the gasket included in the kit.

7. Re-install in reverse order.

Figure 22.1

Exhaust Blower

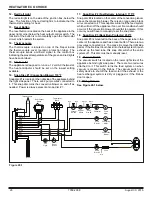

C. Snap Disc Replacements

Snap Disc #1 - Convection Blower

1. Turn down thermostat, let appliance cool completely if

running. Then unplug appliance before servicing.

2. Using #2 Phillips screwdriver, 3/8” wrench, or 3/8” socket

loosen the three screws that hold the right upper and

lower side panels in place. You do not need to remove

the screws. Remove side panels by lifting up and out.

3. Snap disc #1 is located on the convection plenum below

the feed motor.

Figure 22.1

.

4. It has two purple wires attached to it with 1/4 inch female

spade terminals.

5. Disconnect the two wires from the snap disc. Using a #2

Phillips screwdriver, remove the two screws securing the

snap disc to the appliance.

6. Re-install in reverse.

Snap Disc #2 - Fuel Delivery Interrupt

1. Turn down thermostat, let appliance cool completely if

running. Then unplug appliance before servicing.

2. Using #2 Phillips screwdriver, 3/8” wrench, or 3/8” socket

loosen the three screws that hold the right upper and

lower side panels in place. You do not need to remove

the screws. Remove side panels by lifting up and out.

3. Snap disc #2 is located on the convection plenum in the

center of the appliance above the convection blower.

Figure 22.2

.

4. It has a black wire and an orange wire attached to it with

1/4 inch female spade terminals.

5. Disconnect the two wires from the snap disc. Using a #2

Phillips screwdriver, remove the two screws securing the

snap disc to the appliance.

6. Re-install in reverse.

Snap Disc #3 - Feed Motor - Manual Reset

1. Turn down thermostat, let appliance cool completely if

running. Then unplug appliance before servicing.

2. Using #2 Phillips screwdriver, 3/8” wrench, or 3/8” socket

loosen the three screws that hold the right upper and

lower side panels in place. You do not need to remove

the screws. Remove side panels by lifting up and out.

3. Snap disc #3 is located on the bracket on the feed tube

near the feed motor.

Figure 22.1

.

4. It has a two gray wires attached to it with 1/4 inch female

spade terminals.

5. The locating bracket is attached to the feed tube with an 8

X 32 wing nut. Remove the wing nut to detach the bracket

from the feed tube.

5. Disconnect the two wires from the snap disc.

6. Using a #2 Philips screwdriver, remove the screw secur-

ing the snap disc to the bracket.

Figure 23.1 on page 23

.

7. Re-install in reverse.

Figure 22.2

Snap Disc #1

Snap Disc #3

Snap Disc #2