6

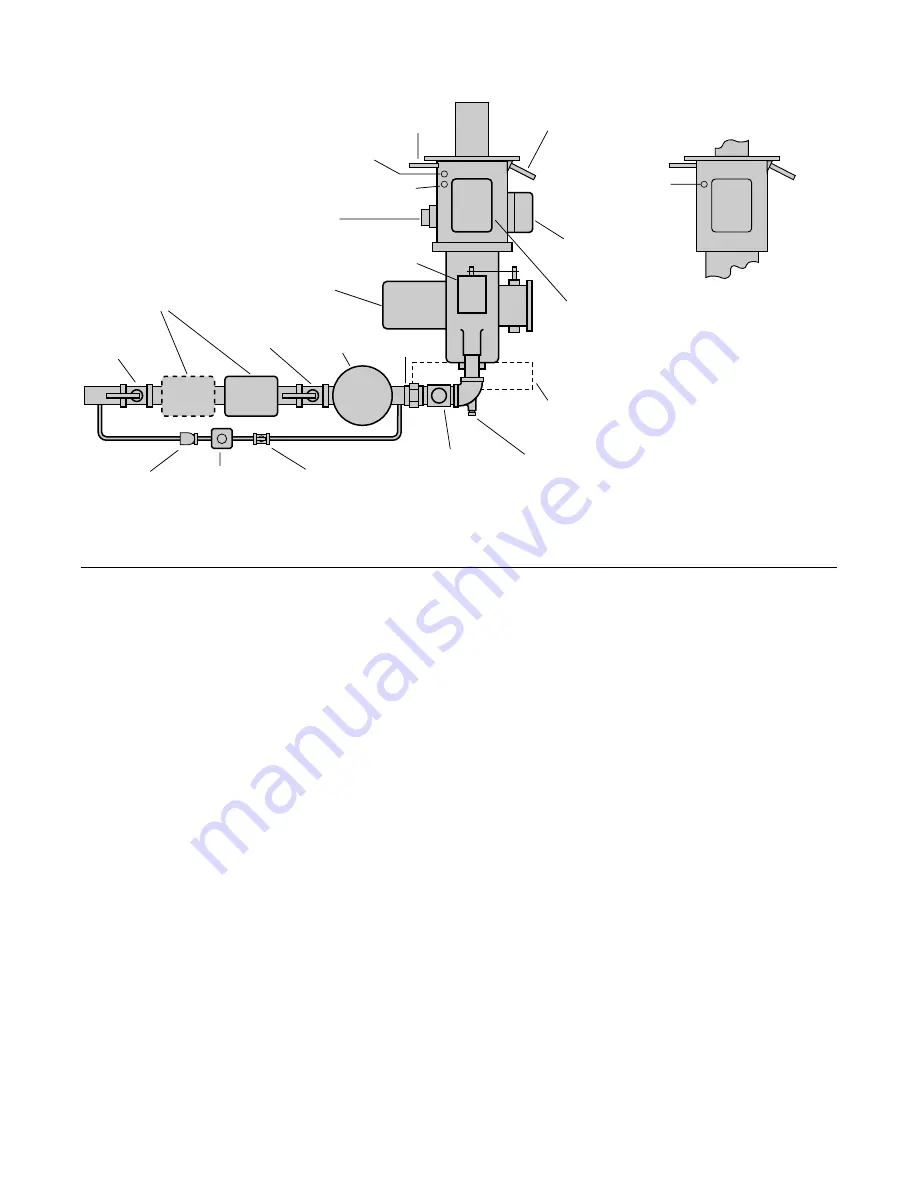

Figure 5 – Components Identification

5.0 Start-Up & Adjustment

Refer to the above illustration for component identification and location.

Initial Start-up Instructions

Close the manual main gas and pilot gas cocks.

Turn the burner on/off switch to “on.”

Open the manual main gas cock and then the pilot gas cock. Always open these two

valves in this sequence; reversing the sequence may blow out the pilot as the control

motor moves to the high fire position.

After the pilot gas cock is opened, the pilot should light, the automatic main gas valve

should open to establish a low fire flame, and the control motor should move the air

butterfly valve to the open—or high fire—position. Pilot gas flow is set at the Eclipse

factory during test firing and should be satisfactory for most applications. If pilot adjust-

ment is required, see the detailed instructions in Figure 7. Pilot gas flow should be the

minimum that will give reliable ignition and a steady flame signal.

Check Flue Gas

Drive the burner to high fire. Using a flue gas analyzer, measure the flue gas compo-

nents in the exit end of the immersion tube. Adjust the gas butterfly to produce 2 to

4% O

2

, or 10 to 10.5% CO

2

for natural gas.

Adjust High Fire Gas Flow

Using Tag Settings: Each burner is test fired at Eclipse before shipment and supplied

with a tag (Figure 6) showing the differential gas pressure that corresponds to maxi-

mum rated input. Attach a manometer as shown in Figure 6, and, if necessary, adjust

the air butterfly linkage until the gas differential pressure matches the pressure drop re-

corded on the tag. The differential pressure on the tag is for natural gas. For propane,

multiply this pressure by 0.4.

Using A Gas Metering Orifice: If a gas metering orifice was installed to provide more

accurate gas flow measurements, use a manometer to measure the pressure drop

across the orifice. If necessary, adjust the air butterfly linkage to produce the pressure

drop that corresponds to the desired high fire gas flow.

Ignition

Transformer

Flame Monitor

(Standard

Burner Only)

Wiring Box

IRI Only

Ignition Plug

#18193

Air Flow Switch

Control Motor

Blower Motor

Pilot

Solenoid

Pilot

Regulator

Pilot

Adjusting Cock

Peepsight

Union

Flame Rod Port,

1/2" N.P.T.

Use Rod

#16946-1**

U.V. Scanner,

124 IP*

U.V. Scanner,

132 IP*

U.V. Scanner,

140, 148 & 156 IP*

* All U.V. scanner ports are 1/2"

N.P.T. Install the scanner in these

ports when it is substituted for a

flame rod.

** Cut the electrode length to 4-1/2"

(114mm) for the 124 & 132 IP, and

5" (127mm) for the 140, 148 & 156 IP

Gas Adjusting

Valve

Manual

Main

Gas Cock

Automatic Gas

Shut-Off Valve(s)

Manual

Main

Gas Cock

Proportionator